SPRUJ64 September 2022

- Abstract

- Trademarks

- 1Key Features

- 2AM64x SKEVM Overview

- 3Functional Block Diagram

-

4System Description

- 4.1 Clocking

- 4.2 Reset

- 4.3 Power Requirements

- 4.4 Configuration

- 4.5 JTAG

- 4.6 Test Automation

- 4.7 UART Interface

- 4.8 Memory Interfaces

- 4.9 Ethernet Interface

- 4.10 USB 3.0 Interface

- 4.11 PRU Connector

- 4.12 User Expansion Connector

- 4.13 MCU Connector

- 4.14 Interrupt

- 4.15 I2C Interface

- 4.16 IO Expander (GPIOs)

- 5Known Issues and Modifications

- 6Revision History

4.6 Test Automation

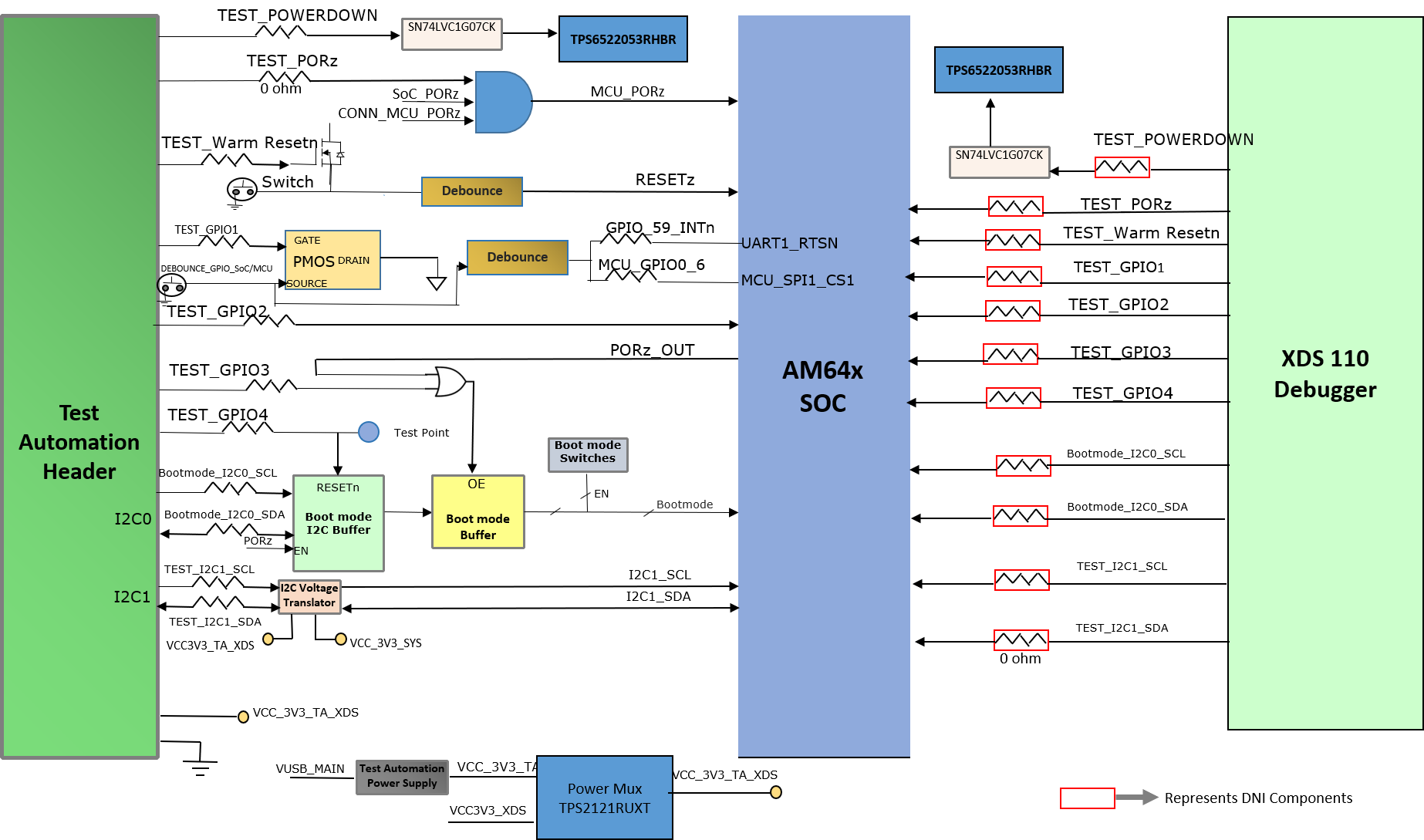

The SKEVM has a 40-pin test automation header (J16) to allow an external controller to manipulate some basic operations such as Power Down, POR, Warm Reset, Boot Mode control, and so forth. The test automation header includes four GPIOs and two I2C interfaces (I2C1, Boot mode I2C0).

The test automation circuit has voltage translation circuits so that the controller is isolated from the IO voltages used by the AM64x. Boot mode for the AM64x must be controlled by either the user using DIP Switches or the test automation header through the I2C IO Expander.

Boot Mode Buffers are used to isolate the Boot Mode controls driven through DIP Switches or the I2C IO Expanders. Power to Test Automation Circuit is provided from a Power Mux (TPS2121RUXT), which has the input supplies VCC3V3_TA supply generated from a dedicated regulator and VCC3V3_XDS generated from an LDO (it is the supply for XDS110 Debugger section). The basic controls of test automation header J16 are as follows. Table 4-14 gives details about test automation header signals.

Optionally, the Test Automation header functionality can be implemented by the XDS110 controller. Hence resistor options (R420, R421, R422, R423, R424, R425, R426, R427, R436, R437, R438, and R439) are provided for Power Down, POR, Warm Reset, Boot Mode controls, and GPIO signals. By default, these resistors are made as DNI so that an external controller controls the basic operations through the Automation header. When the firmware for the XDS110 is developed, mount the above mentioned resistors and DNI the resistors R380, R381, R382, R383, R384, R385, R386, R432, R433, R434, and R435 to control the basic operations through the XDS110 microcontroller.

Proper Isolation to be provided on Boot Mode signals to allow normal operation. Two I2Cs are available on the test automation header. SoC _I2C [1] is connected to test automation header to communicate with external controller, and the other I2C is connected to Boot mode buffer to control boot mode of AM64x.

Table 4-14 lists the reset signals routed from test automation header. The boot mode for the AM64x can be controlled by either the user or the test automation header.

| Signal | Signal Type | Function |

|---|---|---|

| POWER_DOWN | GPIO | Used to Power down the Board |

| PORZn | GPIO | Used to Reset the SoC PORz |

| WARM_RESETn | GPIO | Used to Reset the SoC Warmreset |

| GPIO1 | GPIO |

Used to Generate the interrupt on GPIO1_59_INTn Pin |

| GPIO2 | GPIO | GPIO for communication with AM64X |

| GPIO3 | GPIO | Used to Enable the BOOTMODE Buffer |

| GPIO4 | GPIO | Used to Reset the Boot mode IO Expander |

| Bootmode I2C0 | I2C | Communicates with boot mode I2C buffer |

| I2C1 | I2C | Communicates with AM64x |

If the test automation circuit is going to control the boot mode, all the switches must be manually be set to the off position. The pins used for boot mode also have other functions which are isolated by disabling the boot mode buffer during normal operation. Figure 4-6 shows the test automation signal connection with AM64x.

Figure 4-6 Test Automation Header

Figure 4-6 Test Automation HeaderTest Automation Header signals are optionally connected to the XDS110 microcontroller through zero ohm resistors. By default, those resistors are made as DNI.

| TM4C1294 PIN Name | Signal Name |

|---|---|

| PM0 | TEST_POWERDOWN |

| PM1 | TEST_PORZn |

| PM2 | TEST_WARMRESETn |

| PM3 | TEST_GPIO1 |

| PM4 | TEST_GPIO2 |

| PM5 | TEST_GPIO3 |

| PM6 | TEST_GPIO4 |

| PM7 | TEST_POWERDOWN |

| PG0 | TEST_PORZn |

| PG1 | TEST_WARMRESETn |

Table 4-16 lists test automation header’s pin-out and IO direction.

| Pin No. | Signal Name | IO Direction (wrt SoC) |

|---|---|---|

| 1 | VCC3V3_TA | Power (out) |

| 2 | VCC3V3_TA | Power (out) |

| 3 | VCC3V3_TA | Power (out) |

| 4 | NC | NA |

| 5 | NC | NA |

| 6 | NC | NA |

| 7 | DGND | Ground |

| 8 | NC | NA |

| 9 | NC | NA |

| 10 | NC | NA |

| 11 | NC | NA |

| 12 | NC | NA |

| 13 | NC | NA |

| 14 | NC | NA |

| 15 | NC | NA |

| 16 | DGND | Ground |

| 17 | NC | NA |

| 18 | NC | NA |

| 19 | NC | NA |

| 20 | NC | NA |

| 21 | NC | NA |

| 22 | NC | NA |

| 23 | NC | NA |

| 24 | NC | NA |

| 25 | DGND | Ground |

| 26 | TEST_POWERDOWN | Input |

| 27 | TEST_PORZn | Input |

| 28 | TEST_WARMRESETn | Input |

| 29 | NC | NA |

| 30 | TEST_GPIO1 | Bidirectional |

| 31 | TEST_GPIO2 | Bidirectional |

| 32 | TEST_GPIO3 | Input |

| 33 | TEST_GPIO4 | Input |

| 34 | DGND | Ground |

| 35 | NC | NA |

| 36 | SOC_I2C1_TA_SCL | Bidirectional |

| 37 | BOOTMODE_I2C_SCL | Bidirectional |

| 38 | SOC_I2C1_TA_SDA | Bidirectional |

| 39 | BOOTMODE_I2C_SDA | Bidirectional |

| 40 | DGND | Ground |

| 41 | DGND | Ground |

| 42 | DGND | Ground |