ZHCSO18A december 2022 – june 2023 TPS281C30

PRODUCTION DATA

- 1

- 1 特性

- 2 应用

- 3 说明

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Parameter Measurement Information

- 9 Detailed Description

- 10Application and Implementation

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

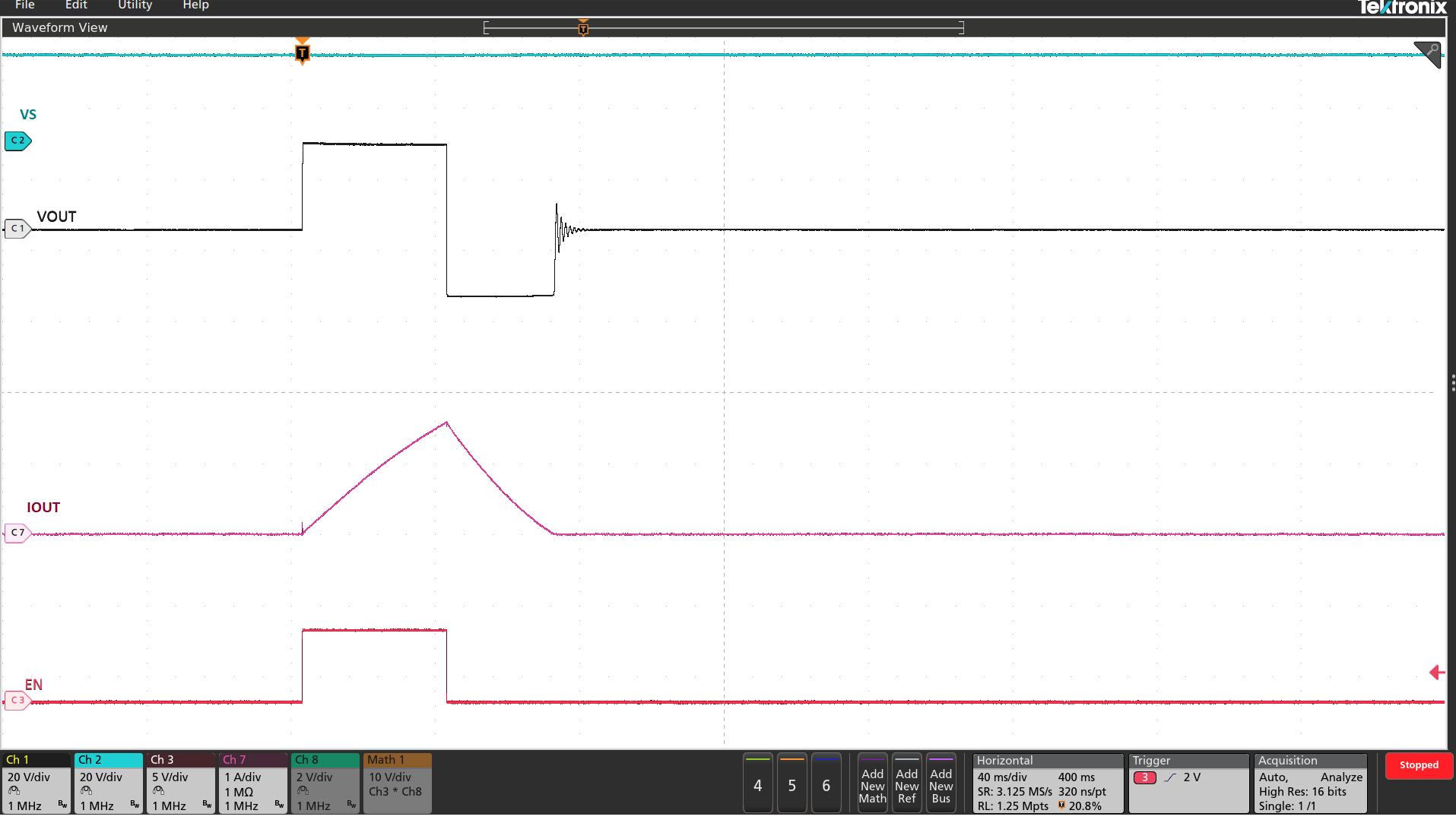

9.4.4 Inductive Load Demagnetization

When switching off an inductive load, the inductor can impose a negative voltage on the output of the switch. The TPS281C30 includes voltage clamps between VS and VOUT to limit the voltage across the FETs and demagnetize load inductance if there is any. The negative voltage applied at the OUT pin drives the discharge of inductor current. Figure 10-14 shows the device discharging a 400-mH load.

Figure 9-13 TPS281C30 Inductive Discharge (400 mH).

Figure 9-13 TPS281C30 Inductive Discharge (400 mH).  Figure 9-14 TPS281C30 Inductive Load Discharge Energy Capability at 125°C.

Figure 9-14 TPS281C30 Inductive Load Discharge Energy Capability at 125°C.