SLDA021B March 2014 – February 2020 AM3892 , AM3894

8.6 Site Redressing

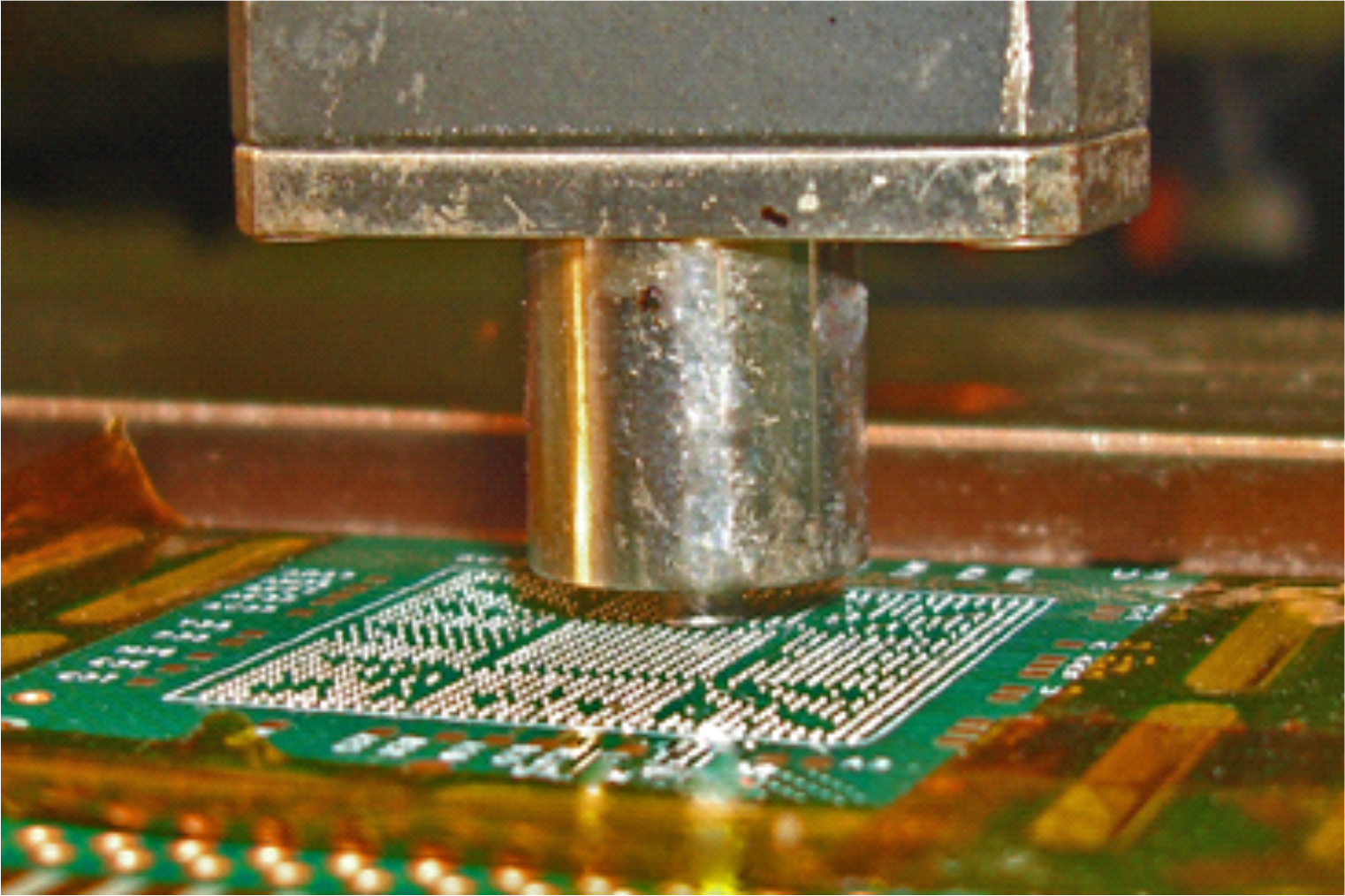

Excess solder that remains on the PCB pads should only be removed by automated vacuum scavenging, preferably with automatic height control, as shown in Figure 10.

Figure 10. Example of Automated Vacuum Removal of Excess Solder from Pads

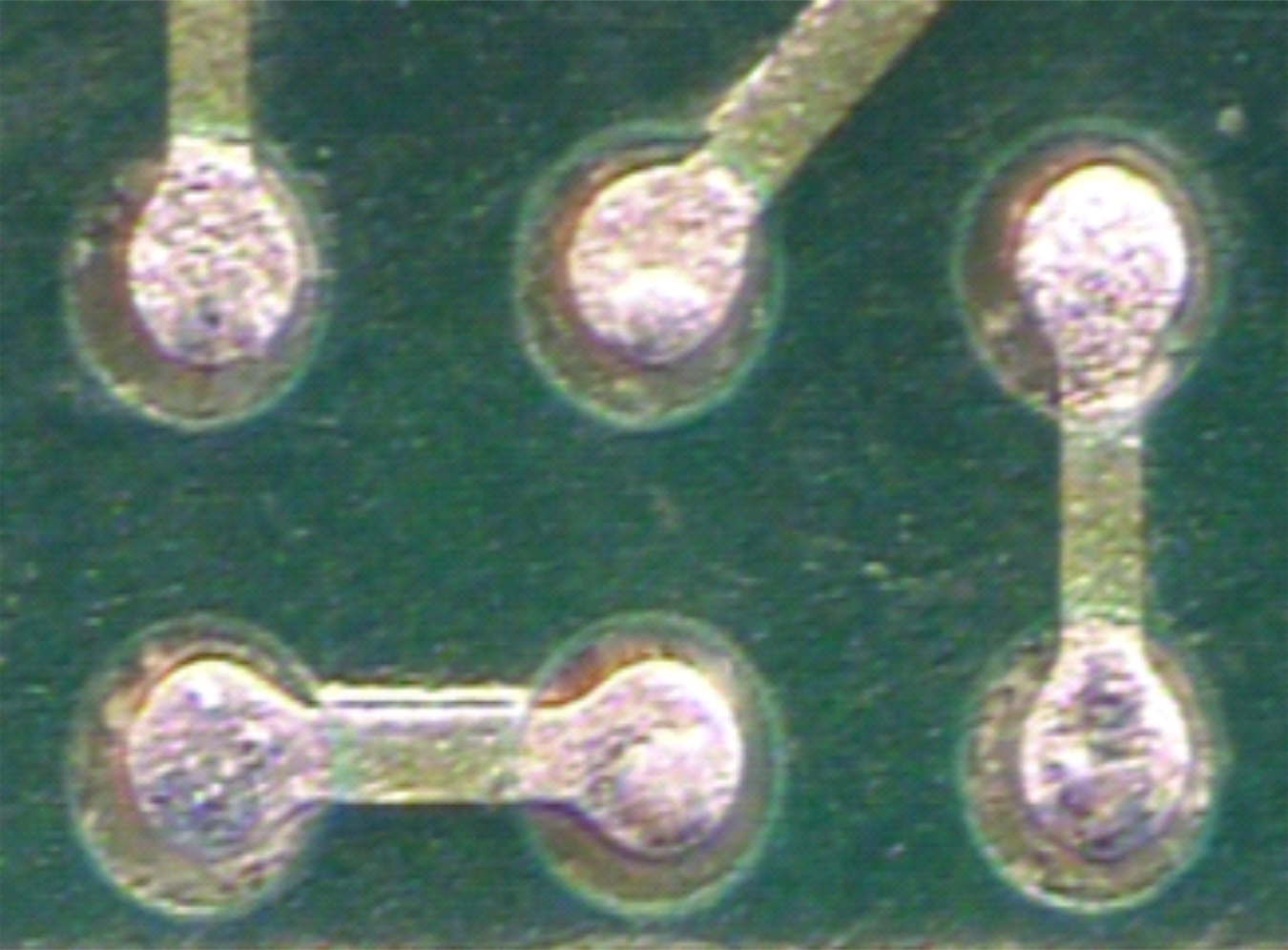

Figure 10. Example of Automated Vacuum Removal of Excess Solder from Pads After scavenging, some solder should remain on the pads, as shown in Figure 11.

Figure 11. Example of Cleaned PCB Pads Ready to Accept Fresh Solder Paste

Figure 11. Example of Cleaned PCB Pads Ready to Accept Fresh Solder Paste The pitch and population density 0.65mm devices preclude manual vacuum scavenging or solder wicking with braid. Both manual processes are likely to lift pads and/or damage solder mask, and therefore are not recommended.