SLDA021B March 2014 – February 2020 AM3892 , AM3894

8.4 Reflow Profile Considerations

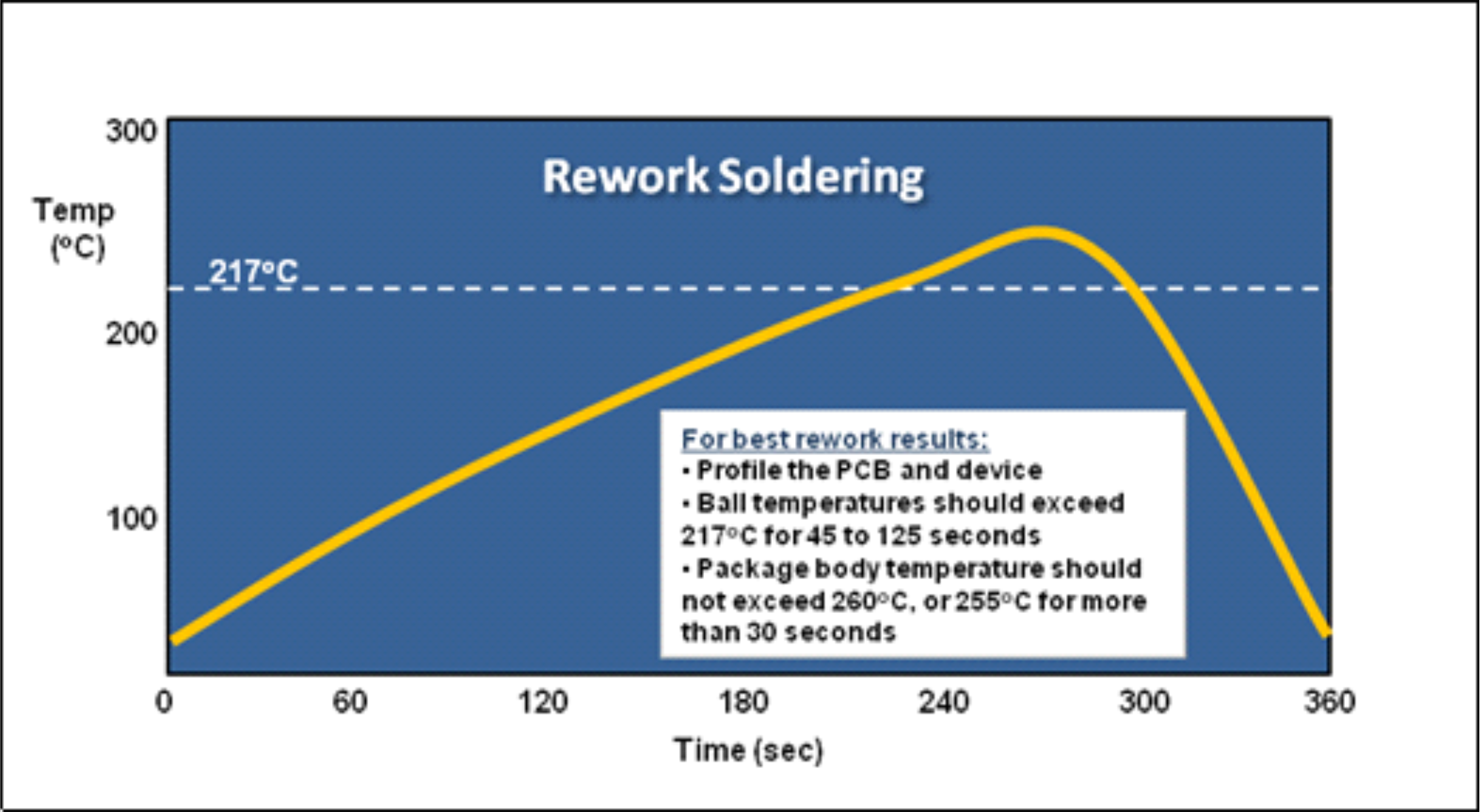

Thermal profile considerations are similar to those for the mass reflow of the PCB:

Preheat should be applied from both sides of the PCB.

Some rework stations offer optional body cooling. If the machine is equipped with this option, it should be used. If it is not equipped, care should be taken to insure the package body temperature does not exceed 260°C, and does not exceed 255°C for more than 30 seconds.

If small discrete components are located close enough to the edges of the package to get reflowed during the thermal process, they may be temporarily removed and resoldered after the rework is completed, or they can be covered with polyimide tape to maintain their position during the BGA removal and replacement process.

Figure 8 shows a typical rework profile.

Figure 8. Rework Profile Considerations

Figure 8. Rework Profile Considerations