SLDA021B March 2014 – February 2020 AM3892 , AM3894

8.5 Device Removal and Inspection

A standard square nozzle matched to the package size is recommended for device removal and replacement. Air or nitrogen may be used as a gas medium. Once all the solder joints have reached liquidus temperatures, the device should be lifted directly off the board with the rework machine’s vacuum head. The component should be scrapped and replaced with a new device. Removing and re-using the component can impact its reliability.

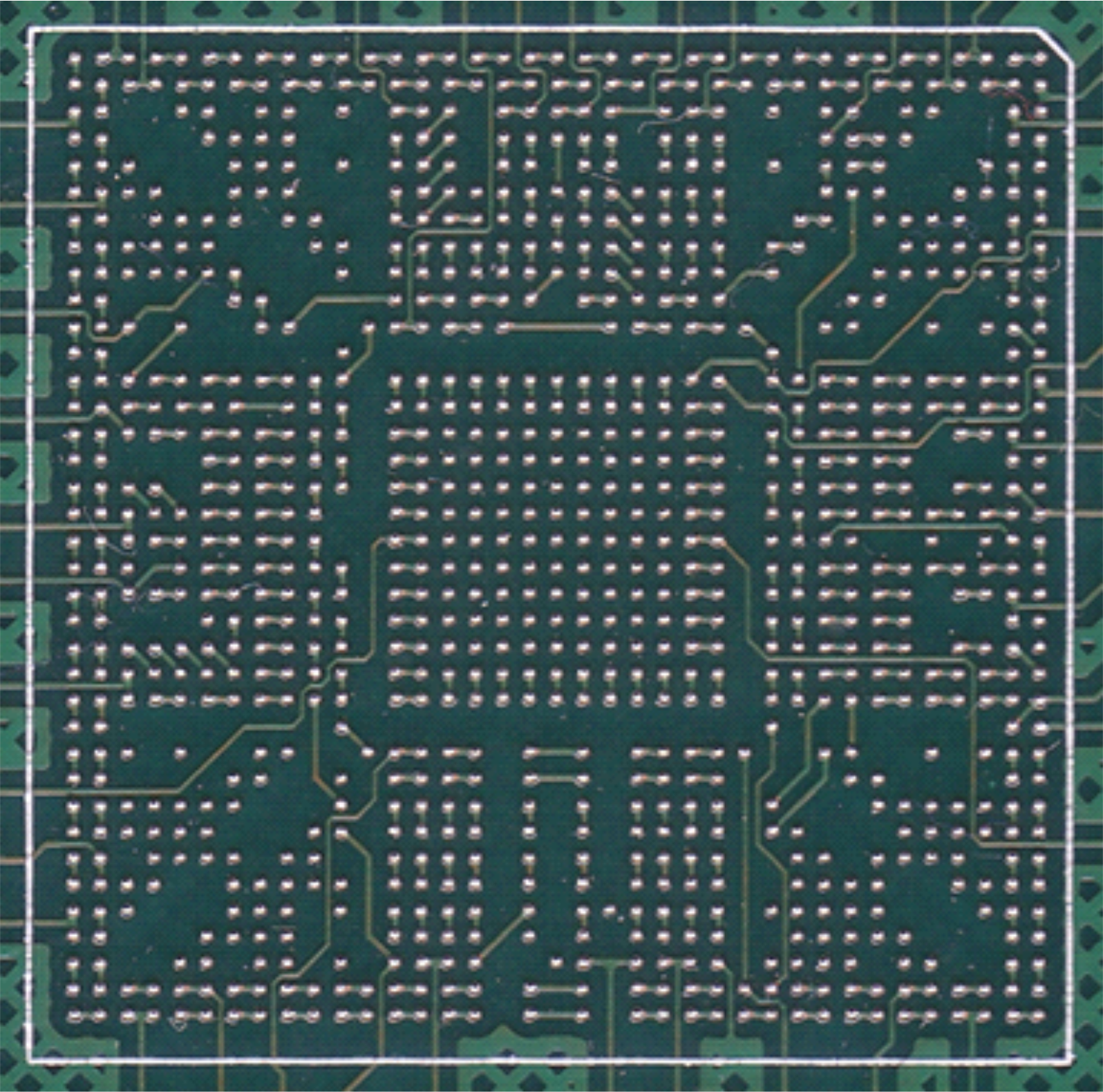

The PCB should also be inspected to insure no solder mask or pads have been lifted in the process, as seen in Figure 9. If pads are lifted, the PCB should be scrapped, as some of the pads contain microvias. If solder mask has been lifted, it may be repaired using standard mask repair supplies and techniques.

Figure 9. Example of PCB Inspection after Device Removal

Figure 9. Example of PCB Inspection after Device Removal