SLAU857A May 2021 – July 2021 MSP430FR2476 , MSP430FR2512 , MSP430FR2522 , MSP430FR2532 , MSP430FR2533 , MSP430FR2632 , MSP430FR2633 , MSP430FR2672 , MSP430FR2673 , MSP430FR2675 , MSP430FR2676

4.2.1 Schematic Design

The main concern of the schematic design is both to ensure that the MCU function is normal and to maximize EMC anti-noise performance. Table 4-3 is a checklist for schematic design. For specific design solutions, refer to the device-specific data sheet, or refer to the EVM schematic diagram in Section 3.3.

| Number | Classification | Component | Recommendation | |

|---|---|---|---|---|

| 1 | Smallest system | Reset and programming circuit | Add 47-kΩ pullup resistor and 1-nF pulldown capacitor to Reset pin. | |

| 2 | Power supply circuit | Add 10-µF and 0.1-µF capacitors to VCC and GND, and place them close to the MCU. | ||

| 3 | Capacitive touch | VREG filter circuit | Add 1-µF capacitance to ground close to VREG pin, ESR ≤200 mΩ. | |

| 4 | Series resistance on CAP I/O | Add a 470-Ω to 10-kΩ resistor close to the MCU pin for ESD protection and anti-noise filtering. | ||

| 5 | CAP I/O pin assignment (if possible) | It is recommended to use the “Auto-Assign” function of CapTIvate Design Center to assign CAP I/O pins. In addition to buttons and proximity sensors, scroll wheels, sliders, and touch panels have sequence requirements for scanning the CAP I/O pins. The Auto-Assign function includes this sequence to assign scroll wheels, sliders, and touch panel CAP I/O pins after configuring the buttons. | ||

| 6 | EMC anti-noise (Optional) | EMC filter capacitor | For mutual-capacitive applications, add 68 pF of capacitance to ground between the series resistance on the RX pin and the sensor electrode. | |

| 7 | TVS diode | Add a 3.3-V TVS tube with low leakage and low parasitic capacitance between the CAP I/O series resistance and the electrode. Add a general TVS tube to the power supply and external connection line. | ||

| 8 | Common mode inductors/magnetic beads | Add common mode inductance and magnetic beads to the power supply as needed. | ||

| 9 | Others | I2C communication line pullup resistor | Add 2.2-kΩ pullup resistor. | |

| 10 | I2C communication pins (GUI default configuration) | MSP430FR25x2: P2.4: IRQ (OPEN DRAIN) P2.5: UCB0 I2C SDA P2.6: UCB0 I2C SCL | MSP430FR263x, MSP430FR253x, MSP430FR267x: P1.1: IRQ (OPEN DRAIN) P1.2: UCB0 I2C SDA P1.3: UCB0 I2C SCL | |

| 11 | UART communication pin (GUI default configuration) | MSP430FR25x2: P2.0: UCA0 UART TXD P2.1: UCA0 UART RXD | MSP430FR263x, MSP430FR253x, MSP430FR267x: P1.4: UCA0 UART TXD P1.5: UCA0 UART RXD | |

| 12 | Boot Loader (BSL) | For BSL pin definition, refer to the Bootloader chapter in the corresponding device datasheet. | ||

| 13 | Button to MCU connector | Will increase the parasitic capacitance to the ground, it is not recommended to use. | ||

| 14 | Test point | Increase the related test points of VCC, GND, communication port. | ||

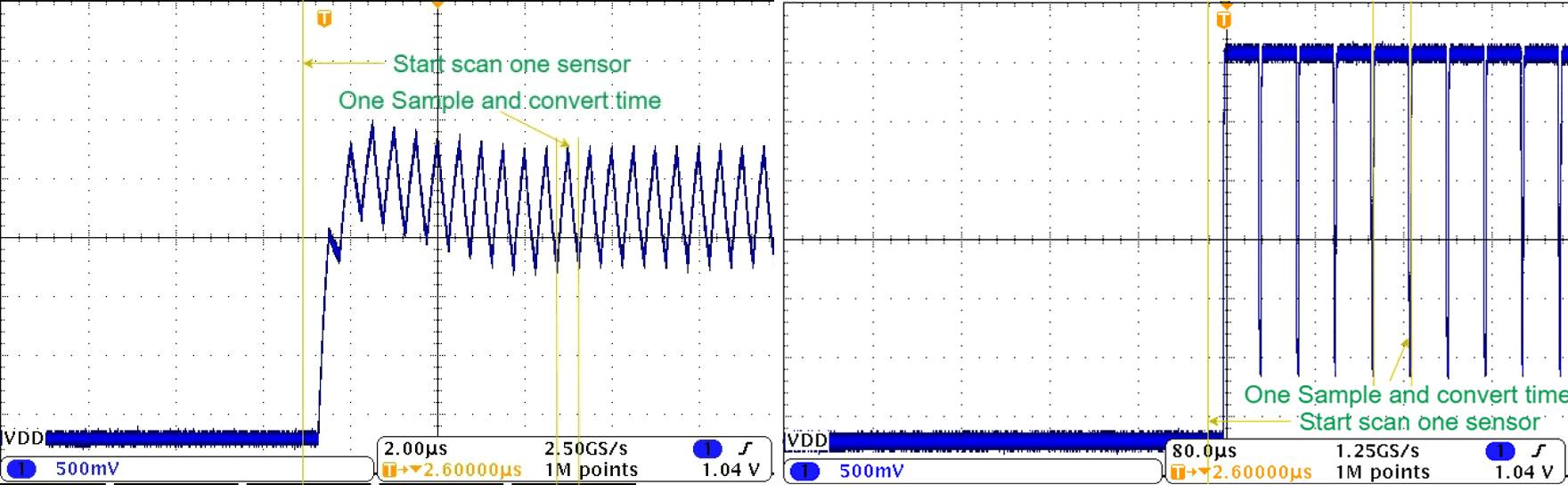

During preliminary evaluation of the EMC anti-noise design, TI recommends allowing for changes to components and layout and finalizing according to the test results. An important choice is the series resistance on the CAP I/O pins. Because the series resistance affects the base capacitance and the capacitance change caused by the touch at the same time, the series resistance itself does not affect the sensitivity of the button. Because it forms a low-pass filter with parasitic capacitance, a larger series resistance can increase the noise immunity of the button. However, too large a resistance affects the charge transfer time. The charge and discharge waveforms on the CAP I/O pins are shown in Figure 4-2. This change to the charge transfer time decreases the sensitivity of the button, which is especially obvious in a self-inductive solution with a larger base capacitance of the sensor. The charge transfer period can be extended and the Frequency Divider parameter in the GUI can be modified to solve the problem.

Figure 4-2 Incomplete and Complete Charge Transfer Cycle (GEN2)

Figure 4-2 Incomplete and Complete Charge Transfer Cycle (GEN2)