SLAU857A May 2021 – July 2021 MSP430FR2476 , MSP430FR2512 , MSP430FR2522 , MSP430FR2532 , MSP430FR2533 , MSP430FR2632 , MSP430FR2633 , MSP430FR2672 , MSP430FR2673 , MSP430FR2675 , MSP430FR2676

5.1.3 Relationships of Parameters in CapTIvate Technology

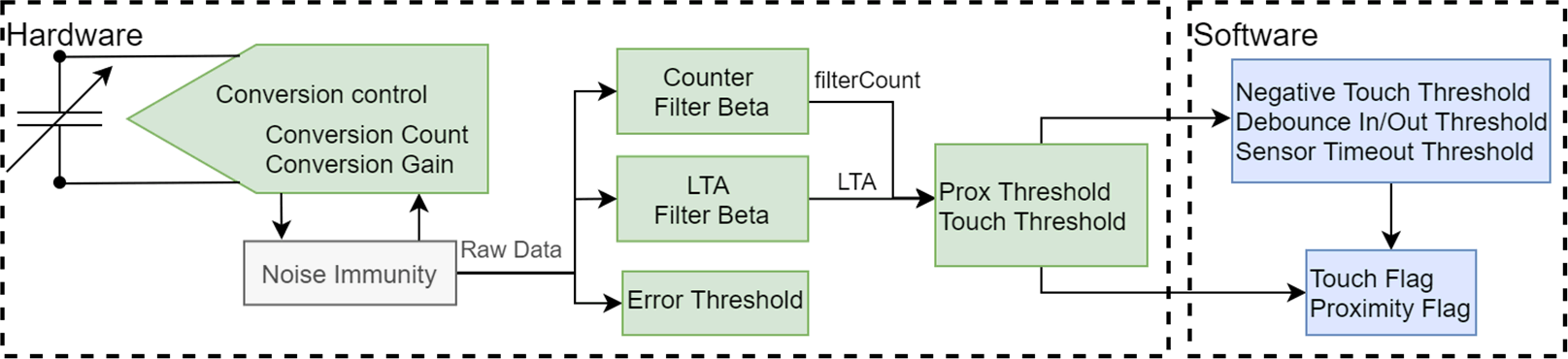

The parameter structure of CapTIvate technology is shown in Figure 5-5. The parameters are divided into hardware configuration parameters and software configuration parameters, all of which are configured in the sensor widget. From this, you can also know which parameters can be automatically updated when the CPU is not working and the CapTIvate MCU is in Wake-on-Prox mode.

Figure 5-5 Parameter Relationships

Figure 5-5 Parameter RelationshipsFirst, the sampling module generates raw data by detecting the external capacitance. Conversion Count and Conversion Gain determine the gain of the sampling module. Then the data passes through the optional anti-noise module (sampling frequency spread spectrum, oversampling, and other functions) to achieve noise filtering. For GEN1, part of the anti-noise function is implemented by software.

The output data is first compared to the Error Threshold. Then filterCount (default is 1) is generated through IIR filtering of different intensities, which is used to characterize real-time capacitance changes, and LTA (Long time average, default is 7) is used to characterize the base capacitance of the environment. Here filterCount corresponds to "Count" in the GUI data monitoring module, and LTA corresponds to "LTA". The Delta between the two is used to characterize the change of capacitance generated by a touch. The relationship between the capacitance change percentage caused by the touch and the filterCount and LTA is shown in Equation 8. For self-capacitance detection, Delta is a positive value, and for mutual-capacitance detection, Delta is a negative value.

The entire signal change process is: when power is on, the calibration function calibrates the equivalent value of the environmental base capacitance to Conversion Count. That is, LTA = Conversion Count. Therefore, Conversion Count can also be understood as a parameter that determines the resolution of the system. At this time, because there is no touch, filterCount=LTA. When touched by a human hand, due to the different filter strengths of the LTA Filter and the Counter Filter, the filterCount changes rapidly, and the Delta increases from 0. When the Prox Threshold is triggered, the LTA Filter is closed and the LTA value remains unchanged. filterCount continues to change, Delta continues to increase, which triggers Touch Threshold. When the hand leaves, if the signal is weaker than the Prox Threshold, the LTA Filter opens and the LTA value starts to refresh. Therefore, the Prox Threshold must be smaller than the Touch Threshold to ensure the normal working mechanism of LTA. In addition, if the Prox Threshold is set too large, human touch causes the LTA to change significantly, and the LTA drifts after multiple consecutive touches, and the system cannot correctly respond to subsequent touches.

Strictly speaking, both Prox Threshold and Touch Threshold are thresholds set for Delta. When triggered, the corresponding global variable of the system is set, and the signal is sent to the subsequent program logic. It should be noted that Prox Threshold is an absolute threshold, while Touch Threshold is a relative threshold. The direct relationship between the two and LTA is shown in Equation 9 and Equation 10. In addition, it can be seen from Equation 8 that Delta has a parallel relationship with ΔCtouch. This is also the reason why Prox/Touch Threshold and Prox/Touch Threshold Percentage are different, because the latter directly characterizes the change in touch capacitance.

Other Thresholds determines the setting events of the Touch flag and Proximity flag of the entire Sensor. For example, the MCU is powered on when a human hand touches. Then, the touch signal of the human hand is counted as the base capacitance of the environment. At this time, removing the finger generates a negative signal. When the negative signal reaches the Negative Threshold, system calibration is triggered. The debounce in and out threshold introduces a signal anti-jitter mechanism to combat noise, which delays the response of the button to a certain extent. The Sensor Timeout Threshold is used to prevent environmental changes from triggering the Prox Threshold situation. After the threshold is triggered, the system recalibrates the environmental base capacitance.