ZHCSI22F October 2017 – December 2021 TPS2662

PRODUCTION DATA

- 1 特性

- 2 应用

- 3 说明

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Parameter Measurement Information

-

9 Detailed Description

- 9.1 Overview

- 9.2 Functional Block Diagram

- 9.3

Feature Description

- 9.3.1 Undervoltage Lockout (UVLO)

- 9.3.2 Overvoltage Protection (OVP)

- 9.3.3 Hot Plug-In and Inrush Current Control

- 9.3.4 Reverse Polarity Protection

- 9.3.5 Overload and Short-Circuit Protection

- 9.3.6 Reverse Current Protection

- 9.3.7 FAULT Response

- 9.3.8 IN, OUT, RTN, and GND Pins

- 9.3.9 Thermal Shutdown

- 9.4 Device Functional Modes

-

10Application and Implementation

- 10.1 Application Information

- 10.2 Typical Application

- 10.3 System Examples

- 10.4 Do's and Don'ts

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

10.2.2.4.1 Case 1: Start-Up Without Load—Only Output Capacitance C(OUT) Draws Current During Start-Up

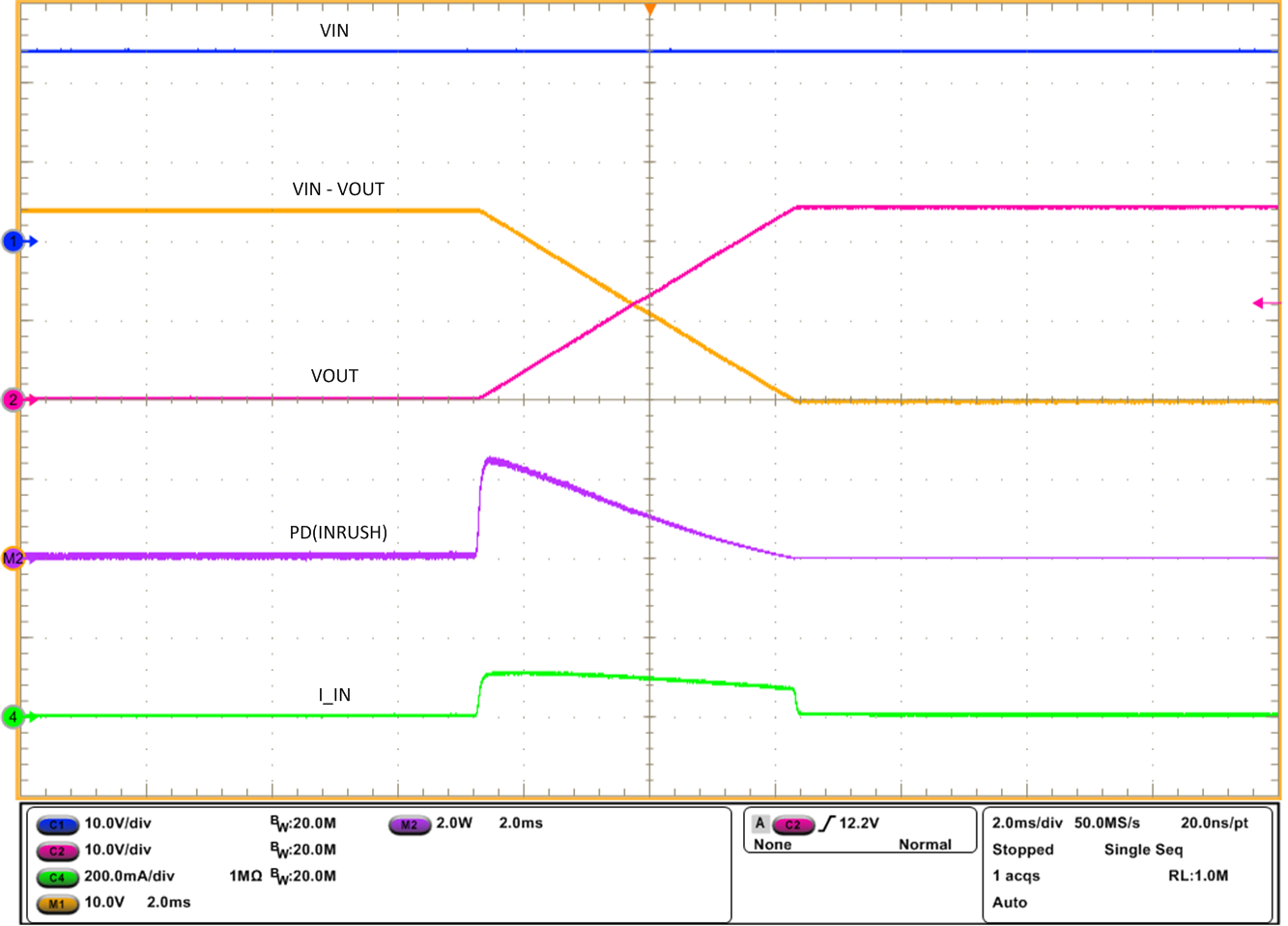

During start-up, as the output capacitor charges, the voltage difference across the internal FET decreases, and the power dissipation decreases. Typical ramp-up of the output voltage, inrush current and instantaneous power dissipated in the device during start-up are shown in Figure 10-2. The average power dissipated in the device during start-up is equal to the area of triangular plot (red curve in Figure 10-3) averaged over tdVdT.

| VIN = 24 V | CdVdT = 10 nF | COUT = 22 µF | |

| VIN = 24 V | CdVdT = 10 nF | COUT = 22 µF | |

The inrush current is determined as shown in Equation 8.

Average power dissipated during start-up is given by Equation 9.

Equation 9 assumes that the load does not draw any current until the output voltage reaches its final value.