SPRUHW1A June 2014 – October 2021 TMS320F28052-Q1 , TMS320F28052M , TMS320F28052M-Q1 , TMS320F28054-Q1 , TMS320F28054M , TMS320F28054M-Q1

- 1Read This First

- 1 F2805xM InstaSPIN-MOTION Enabled MCUs

- 2InstaSPIN-MOTION Key Capabilities and Benefits

- 3InstaSPIN-MOTION Block Diagrams

- 4Application Examples

- 5Evaluating InstaSPIN-MOTION Performance

- 6Microcontroller Resources

5.1 Overview

Large original equipment manufacturers (OEMs) may work with external design houses to optimize their tuning parameters. However, many small and medium size OEMs are challenged by tuning their own PI controls. With InstaSPIN-MOTION, OEMs can save weeks of tuning time.

While PI controls are versatile and applicable to numerous control systems, the tuning process can be complex and time-intensive. Similarly, performance of PI loops can be unpredictable over a wide operating range and as system dynamics change over time. While the use of advanced control techniques, such as model-based compensation, can address these challenges, they require significant time for implementation and testing. They also add complexity to the system, and can result in performance degradation when the system dynamics vary.

InstaSPIN-MOTION addresses these challenges by replacing traditional PI controls. The advantages are highlighted in Table 6-1. InstaSPIN-MOTION incorporates advanced control features, such as feed-forward, an observer, and can be tuned in a fraction of the time required to tuned PI control. Instead of having to tune multiple control parameters, the SpinTAC controller can be tuned by adjusting a single parameter for both position and speed. Once tuned, it performs across a wide-operating range.

| Topic | PI Controllers | InstaSPIN-MOTION |

|---|---|---|

| Performance | Unpredictable across varying speeds and loads. | Compensates for disturbance across the operating range. |

| Tuning Parameters | Multiple sets required for different speed and load points. | Single setting typically effective over the entire operating range. |

| Tuning Process | Complex and underestimated. | Simple - the identification process takes a few minutes. |

| Startup | Difficult - requires control expertise. | Simple - embeds the expertise. |

| Disturbance Recovery | Overshoot and undershoot when disturbances are introduced and during transitions. | Advanced disturbance rejection holds set points more closely. |

InstaSPIN-MOTION is designed to perform in all kinds of systems. In systems that remain unaffected by outside influences, the InstaSPIN-MOTION controller demonstrates its performance benefits by eliminating overshoot and undershoot during transitions.

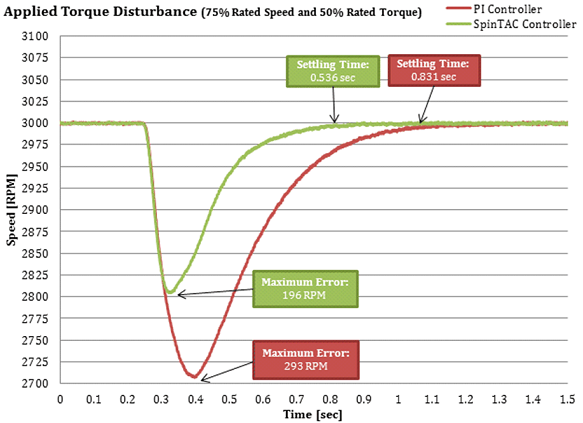

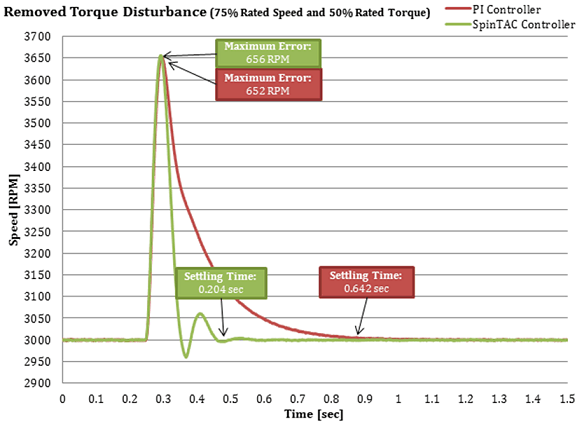

In systems that are affected by outside disturbances, the InstaSPIN-MOTION controller provides advanced disturbance rejection, holding set points more closely than is achievable with standard PI control, as shown in Figure 6-1 and Figure 6-2.

Getting the best possible performance out of your motion system is important. A poorly tuned regulator can result in wasted energy, wasted material, or an unstable system. It is important that speed and position controller performance be evaluated at many different speed and load operating points in order to determine how well it works in your application.

Speed and position controllers can be compared on a number of different factors. However, two metrics — disturbance rejection and profile tracking — can be used to test performance and determine how well your controller is tuned for your application.

Figure 5-1 Applied

Torque Disturbance Comparison

Figure 5-1 Applied

Torque Disturbance Comparison

Figure 5-2 Removed

Torque Disturbance Comparison

Figure 5-2 Removed

Torque Disturbance Comparison