TIDT196 September 2020 – MONTH

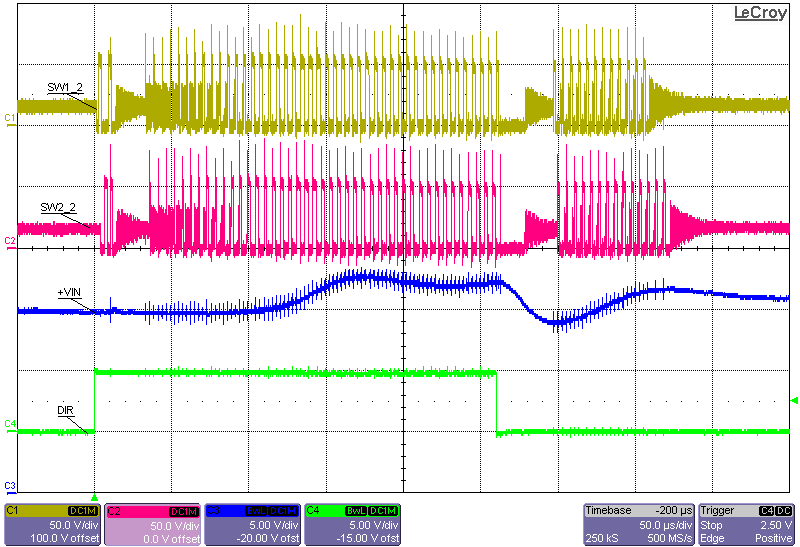

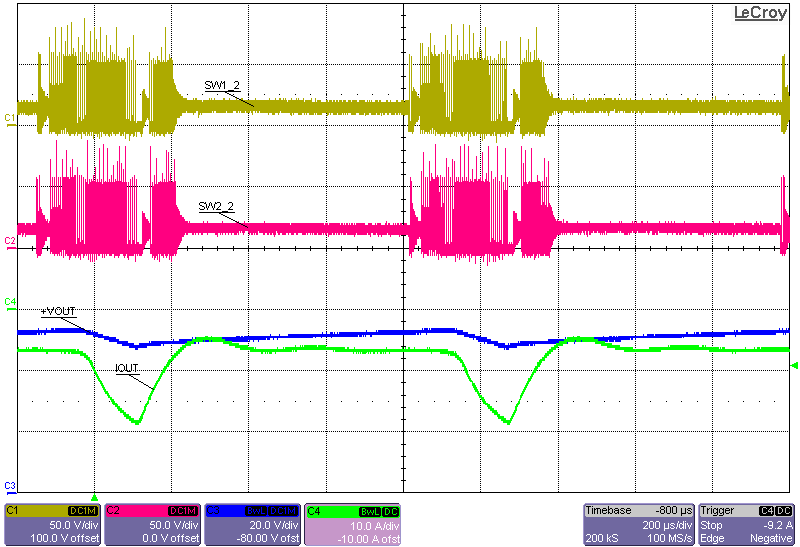

4.5 Reverse Switching

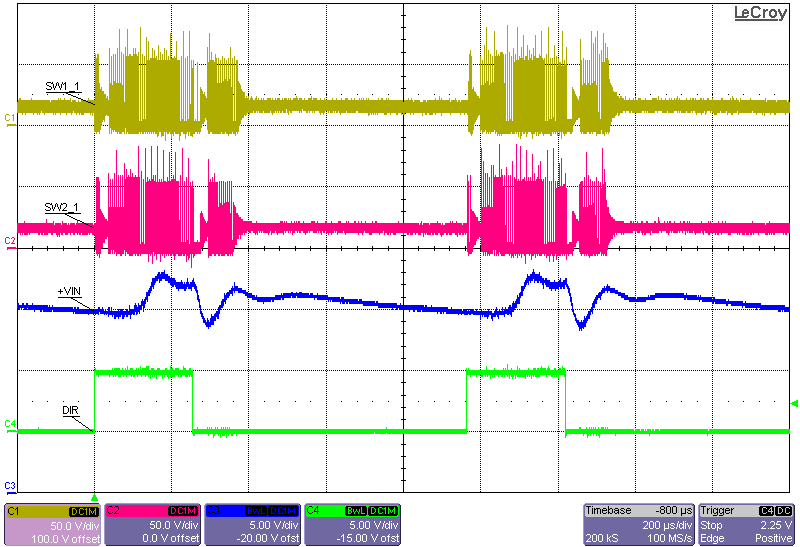

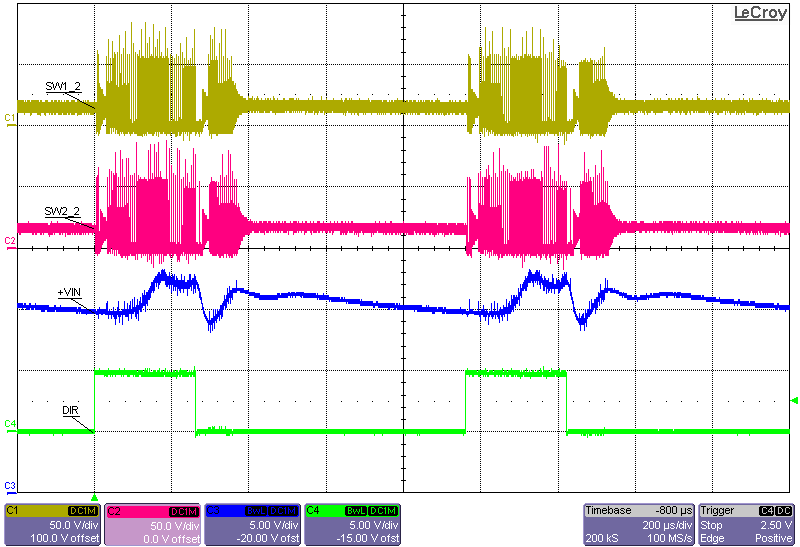

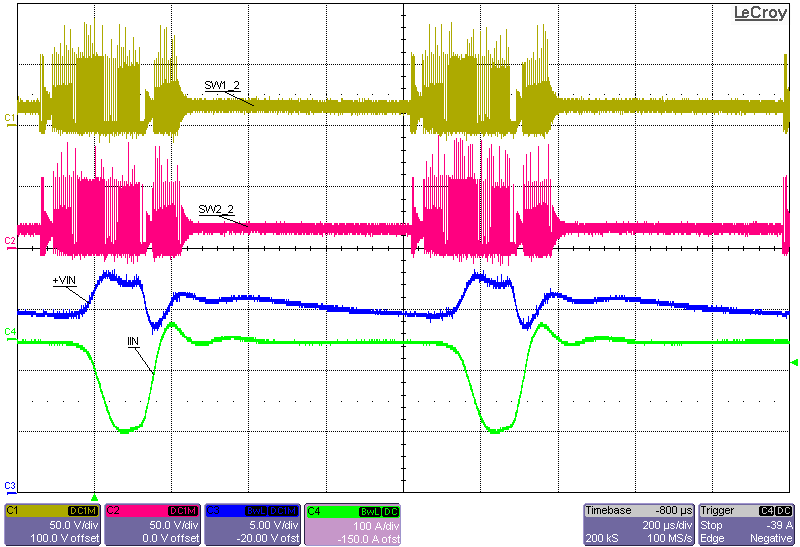

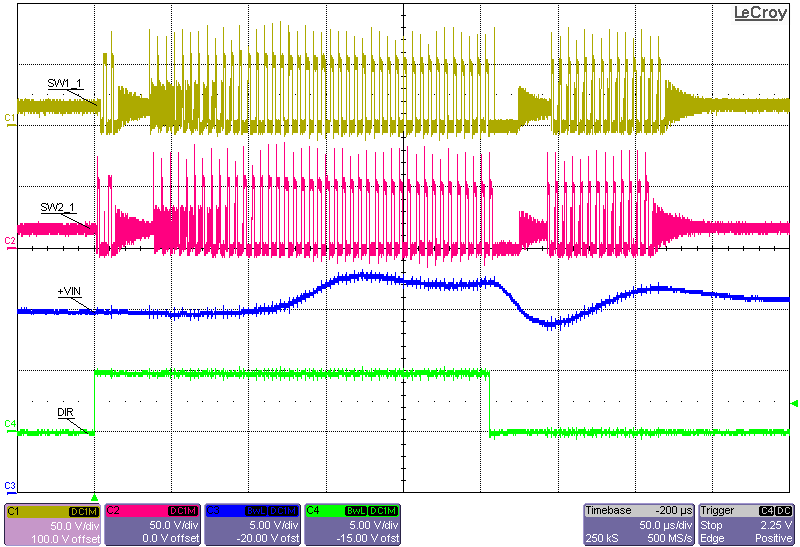

The following figures show reverse switching for two-phase operation. A 14-V constant voltage load is connected across the 12-V input voltage source. The output is powered at no load, and a 54-V 8-A source is connected to the output to test direction reversal. Average power from the 54-V source is 420 W; 12-V source is 56 W; 14-V load is 344 W.

Figure 4-23 Reverse Switching, Phase 1 & 2, Direction Control

Figure 4-23 Reverse Switching, Phase 1 & 2, Direction Control Figure 4-25 Reverse Switching, Phase 3 & 4, Direction Control

Figure 4-25 Reverse Switching, Phase 3 & 4, Direction Control Figure 4-27 Reverse Switching, Phase 3 & 4, Input Voltage and Current

Figure 4-27 Reverse Switching, Phase 3 & 4, Input Voltage and Current Figure 4-24 Reverse Switching, Phase 1 & 2, Direction Control

Figure 4-24 Reverse Switching, Phase 1 & 2, Direction Control Figure 4-26 Reverse Switching, Phase 3 & 4, Direction Control

Figure 4-26 Reverse Switching, Phase 3 & 4, Direction Control Figure 4-28 Reverse Switching, Phase 3 & 4, Output Voltage and Current

Figure 4-28 Reverse Switching, Phase 3 & 4, Output Voltage and Current