SLAA602A June 2013 – August 2017 AMC1100 , SM72295 , TMS320F2802-Q1 , TMS320F28027 , TMS320F28027-Q1 , TMS320F28027F , TMS320F28027F-Q1 , TPS54202 , TPS54231

3 Comparison of Low-Frequency vs. High-Frequency Inverter

There are two simple ways to accomplish the inversion from the energy stored inside the battery or taken from the Solar Panel to the AC power supply capable of running common loads. The prevalent topology has been referred to as the Sine Wave topology by leading manufacturers or technically low-frequency inverter (LF Inverter). The inversion happens as shown below:

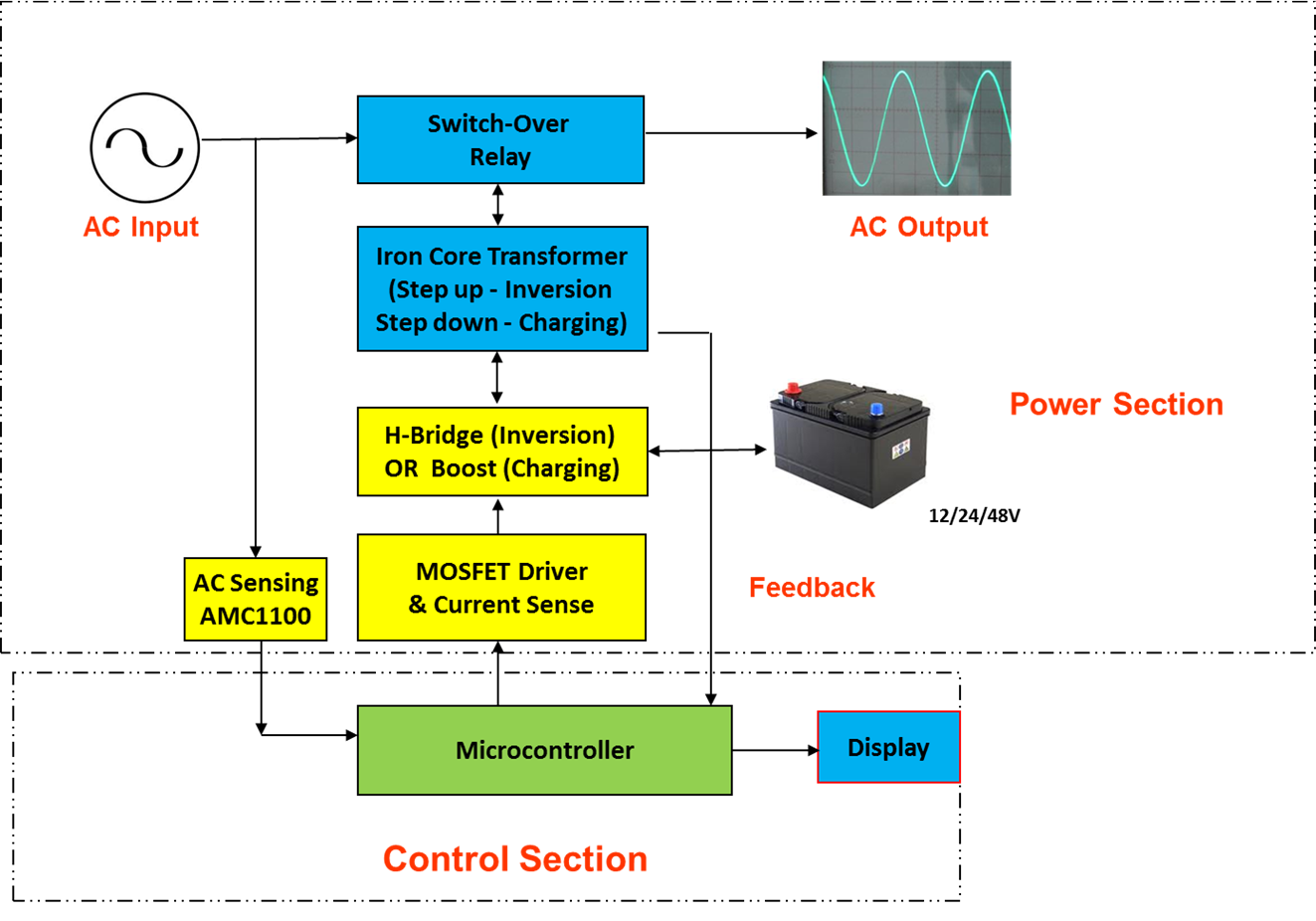

Figure 31. Bidirectional Low Frequency Inverter

Figure 31. Bidirectional Low Frequency Inverter In the LF inverter, the battery voltage is first chopped with the full bridge (using high-frequency PWM, generally 3 kHz to 20 kHz) to an AC waveform. The iron core transformer then boosts the 12-V chopped waveform to 220-V RMS output waveform at 50 Hz. At the output of the transformer, a capacitor helps filters the waveform to make a clean 50-Hz AC Sine Wave. Although this inversion method is widespread today, the iron core transformer is quite bulky and increases the cost of the overall solution. The LF inverters use SM72295 – a highly integrated gate driver with two high-side, current-sensing amplifiers – AMC1100 for AC mains current sensing, along with the LM5017 or TPS54231 for the power supply section.

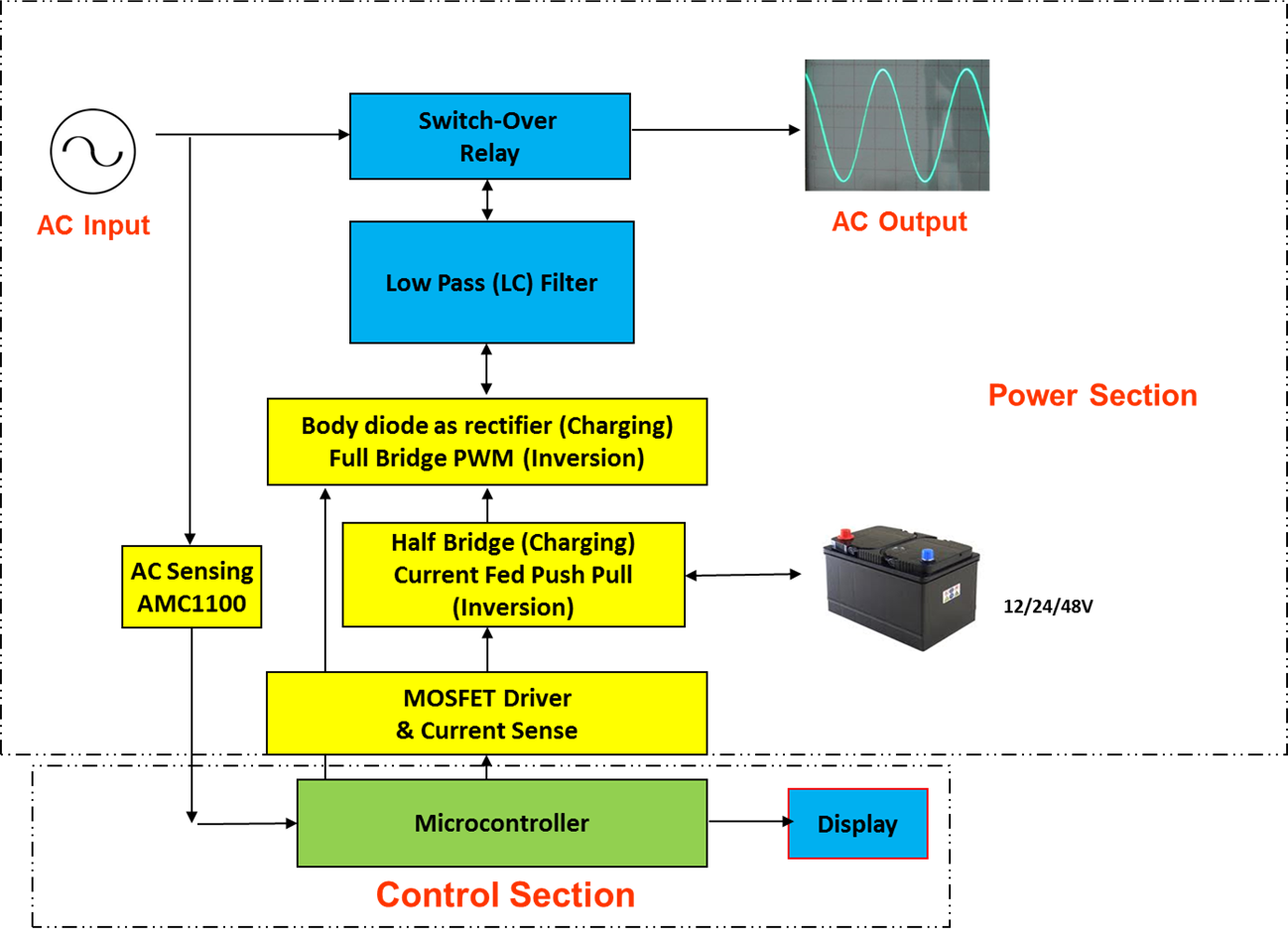

Figure 32. Bidirectional High-Frequency Inverter

Figure 32. Bidirectional High-Frequency Inverter The next advancement in inversion technology is the use of high frequency inverters, or HF inverters. This technology involves more processing complexity but can significantly increase overall system efficiency and eliminate the use of the bulky iron core transformer. In a high-frequency inverter, the battery voltage is converted to an intermediate high DC voltage before it’s converted to an AC waveform using Pulse Width modulation. Here, we demonstrate an example implementation using current fed push-pull topology. During the inverter stage (when the AC mains is not present), the push-pull stage converts the battery voltage to a high voltage in the range of 350 V, which is then chopped with the help of full bridge PWM driven by a microcontroller to form 220-V AC. During the charging stage, the AC main is rectified using the body diodes in the full bridge stage and the second stage acts as half bridge. Thus, bidirectional control is achieved without the need of any additional components.

Although the HF inverter is much higher efficiency that LF inverter, this technology is not very popular for two reasons. First, the use of push -ull stage presents some challenges in the form of voltage overshoots on the MOSFETs, making practice implementation difficult. The possible techniques to solve these issues are passive and active clamping. The passive clamping solves the problem however they lead to higher power dissipation. We employ active clamping in our designs with the help of which we can achieve zero voltage switching (ZVS).

The second challenge is more towards the adoption of this new technology. We see a need of consumer awareness on newer technologies. The implementation of standards, for example STAR rating, in inverters as in other appliances will help. The HF inverter is significantly lighter in weight than its counterpart – LF inverter. The unique challenge most sellers face is that people don’t think they are getting full bang for their buck when they pay for the lighter much-improved design.