ZHCSKX0 February 2020 TPS59632-Q1

PRODUCTION DATA.

- 1 特性

- 2 应用

- 3 说明

- 4 修订历史记录

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3

Feature Description

- 7.3.1 PWM Operation

- 7.3.2 Current Sensing

- 7.3.3 Load-line (Droop)

- 7.3.4 Load Transients

- 7.3.5 Overshoot Reduction (OSR)

- 7.3.6 Undershoot Reduction (USR)

- 7.3.7 Autobalance Current Sharing

- 7.3.8 PWM And SKIP Signals

- 7.3.9 Bias Power (V5A, VDD, And VINTF) UVLO

- 7.3.10 Start-Up Sequence

- 7.3.11 Power Good Operation

- 7.3.12 Analog Current Monitor, IMON, And Corresponding Digital Output Current

- 7.3.13 Fault Behavior

- 7.3.14 Output Under Voltage Protection (UVP)

- 7.3.15 Output Over Voltage Protection (OVP)

- 7.3.16 Over Current Protection (OCP)

- 7.3.17 Over Current Warning

- 7.3.18 Input Voltage Limits

- 7.3.19 VID Table

- 7.4 User Selections

- 7.5 I2C Interface Operation

- 7.6 I2C Register Maps

-

8 Applications and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1

3-Phase D-CAP+™, Step-Down Application

- 8.2.1.1 Design Requirements

- 8.2.1.2

Detailed Design Procedure

- 8.2.1.2.1 Step 1: Select Switching Frequency

- 8.2.1.2.2 Step 2: Set The Slew Rate

- 8.2.1.2.3 Step 3: Set The I2C Address

- 8.2.1.2.4 Step 4: Determine Inductor Value And Choose Inductor

- 8.2.1.2.5 Step 5: Current Sensing Resistance

- 8.2.1.2.6 Step 6: Select Over Current Protection (OCP) Setting

- 8.2.1.2.7 Step 7: Current Monitor (IMON) Setting

- 8.2.1.2.8 Step 8: Set the Load-Line Slope

- 8.2.1.2.9 Step 9: Voltage Feedback Resistor Calculation

- 8.2.1.2.10 Step 10: Ramp Compensation Selection

- 8.2.1.2.11 Step 11 Overshoot Reduction (OSR) selection

- 8.2.1.2.12 Step 12: Undershoot Reduction (USR) selection

- 8.2.1.2.13 Step 13: Loop Compensation

- 8.2.1.3 Application Performance Plots

- 8.2.1

3-Phase D-CAP+™, Step-Down Application

- 9 Power Supply Recommendations

- 10Layout

- 11器件和文档支持

- 12机械、封装和可订购信息

8.2.1.2.8 Step 8: Set the Load-Line Slope

Setting a load line slope is effective in significantly reducing the output capacitors. Therefore, although the design requirement does not call for a load-line, we use the output voltage tolerance specification to determine an appropriate load-line. Figure 23 shows how we first determine the load-line window.

Figure 23. Determination of Nominal DC Load-line window

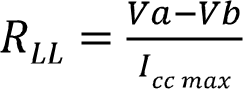

Figure 23. Determination of Nominal DC Load-line window This nominal DC load-line window is now used to set the load-line slope across the range of load current from 0 to Icc,max as shown in Figure 24.

Figure 24. Determination of the Slope of the Load-line

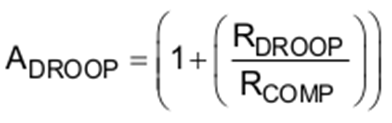

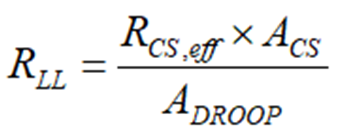

Figure 24. Determination of the Slope of the Load-line The load-line slope RLL is first determined as shown in Figure 24 using the equation in Equation 6. In the device, TPS59632-Q1, the load-line is determined by the current sense resistance, RCS, the current sense amplifier gain, ACS, and the gain of the droop amplifier (ADROOP) as shown in Equation 7.

The gain of the droop amplifier, (ADROOP can therefore be determined by Equation 7. This gain is set by the external resistors RDROOP (between the DROOP pin and the COMP pin) and resistor RCOMP (between the COMP pin and the VREF pin) as shown in Equation 8. We fix the value of RDROOP to 19.6 kΩ, and thereby RCOMP is calculated to 1.87 kΩ.