ZHCSNG8B February 2021 – September 2022 CC2652RSIP

PRODUCTION DATA

- 1 特性

- 2 应用

- 3 说明

- 4 Functional Block Diagram

- 5 Revision History

- 6 Device Comparison

- 7 Terminal Configuration and Functions

-

8 Specifications

- 8.1 Absolute Maximum Ratings

- 8.2 ESD Ratings

- 8.3 Recommended Operating Conditions

- 8.4 Power Supply and Modules

- 8.5 Power Consumption - Power Modes

- 8.6 Power Consumption - Radio Modes

- 8.7 Nonvolatile (Flash) Memory Characteristics

- 8.8 Thermal Resistance Characteristics

- 8.9 RF Frequency Bands

- 8.10 Bluetooth Low Energy - Receive (RX)

- 8.11 Bluetooth Low Energy - Transmit (TX)

- 8.12 Zigbee and Thread - IEEE 802.15.4-2006 2.4 GHz (OQPSK DSSS1:8, 250 kbps) - RX

- 8.13 Zigbee and Thread - IEEE 802.15.4-2006 2.4 GHz (OQPSK DSSS1:8, 250 kbps) - TX

- 8.14 Timing and Switching Characteristics

- 8.15 Peripheral Characteristics

- 8.16 Typical Characteristics

-

9 Detailed Description

- 9.1 Overview

- 9.2 System CPU

- 9.3 Radio (RF Core)

- 9.4 Memory

- 9.5 Sensor Controller

- 9.6 Cryptography

- 9.7 Timers

- 9.8 Serial Peripherals and I/O

- 9.9 Battery and Temperature Monitor

- 9.10 µDMA

- 9.11 Debug

- 9.12 Power Management

- 9.13 Clock Systems

- 9.14 Network Processor

- 9.15 Device Certification and Qualification

- 9.16 Module Markings

- 9.17 End Product Labeling

- 9.18 Manual Information to the End User

- 10Application, Implementation, and Layout

- 11Environmental Requirements and SMT Specifications

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

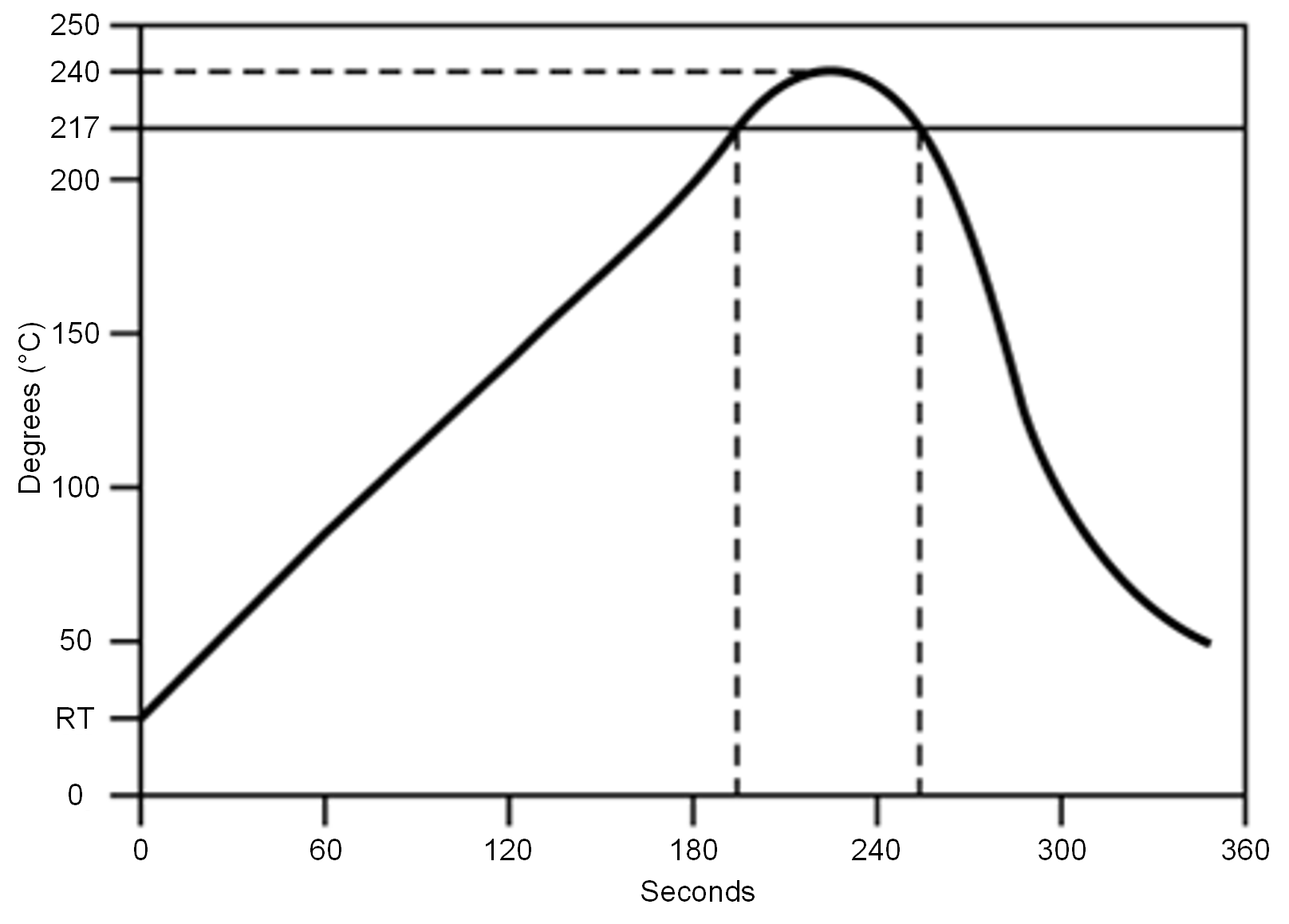

11.6 Soldering and Reflow Condition

- Heating method: Conventional convection or IR convection

- Temperature measurement: Thermocouple d = 0.1 mm to 0.2 mm CA (K) or CC (T) at soldering portion or equivalent method

- Solder paste composition: SAC305

- Allowable reflow soldering times: 2 times based on the reflow soldering profile (see Figure 11-1)

- Temperature profile: Reflow

soldering will be done according to the temperature profile (see

Figure 11-1) - Peak temperature: 260°C

Figure 11-1 Temperature Profile for Evaluation of Solder Heat Resistance of a Component (at

Solder Joint)

Figure 11-1 Temperature Profile for Evaluation of Solder Heat Resistance of a Component (at

Solder Joint)Table 11-1 Temperature Profile

| Profile Elements | Convection or IR(1) |

|---|---|

| Peak temperature range | 235 to 240°C typical (260°C maximum) |

| Pre-heat / soaking (150 to 200°C) | 60 to 120 seconds |

| Time above melting point | 60 to 90 seconds |

| Time with 5°C to peak | 30 seconds maximum |

| Ramp up | < 3°C / second |

| Ramp down | < -6°C / second |

(1) For details, refer to the solder paste manufacturer's

recommendation.

Note:

TI does not recommend the use of conformal coating or similar material on the SimpleLink™ module. This coating can lead to localized stress on the solder connections inside the module and impact the module reliability. Use caution during the module assembly process to the final PCB to avoid the presence of foreign material inside the module.