SNVS118F december 1999 – may 2023 LM2594 , LM2594HV

PRODUCTION DATA

- 1

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Description (continued)

- 6 Pin Configuration and Functions

-

7 Specifications

- 7.1 Absolute Maximum Ratings

- 7.2 ESD Ratings

- 7.3 Recommended Operating Conditions

- 7.4 Thermal Information

- 7.5 Electrical Characteristics – 3.3 V

- 7.6 Electrical Characteristics – 5 V

- 7.7 Electrical Characteristics – 12 V

- 7.8 Electrical Characteristics – Adjustable

- 7.9 Electrical Characteristics – All Output Voltage Versions

- 7.10 Typical Characteristics

- 8 Detailed Description

- 9 Application and Implementation

- 10Device and Documentation Support

- 11Mechanical, Packaging, and Orderable Information

9.1.4 Inductor Selection

All switching regulators have two basic modes of operation: continuous and discontinuous. The difference between the two types relates to the inductor current, whether it is flowing continuously, or if it drops to zero for a period of time in the normal switching cycle. Each mode has distinctively different operating characteristics, which can affect the regulators performance and requirements. Most switcher designs operates in the discontinuous mode when the load current is low.

The LM2594 (or any of the SIMPLE SWITCHER power converter family) can be used for both continuous or discontinuous modes of operation.

In many cases the preferred mode of operation is the continuous mode. This mode offers greater output power, lower peak switch, inductor, and diode currents, and can have lower output ripple voltage. However, the continuous mode requires larger inductor values to keep the inductor current flowing continuously, especially at low output load currents and high input voltages.

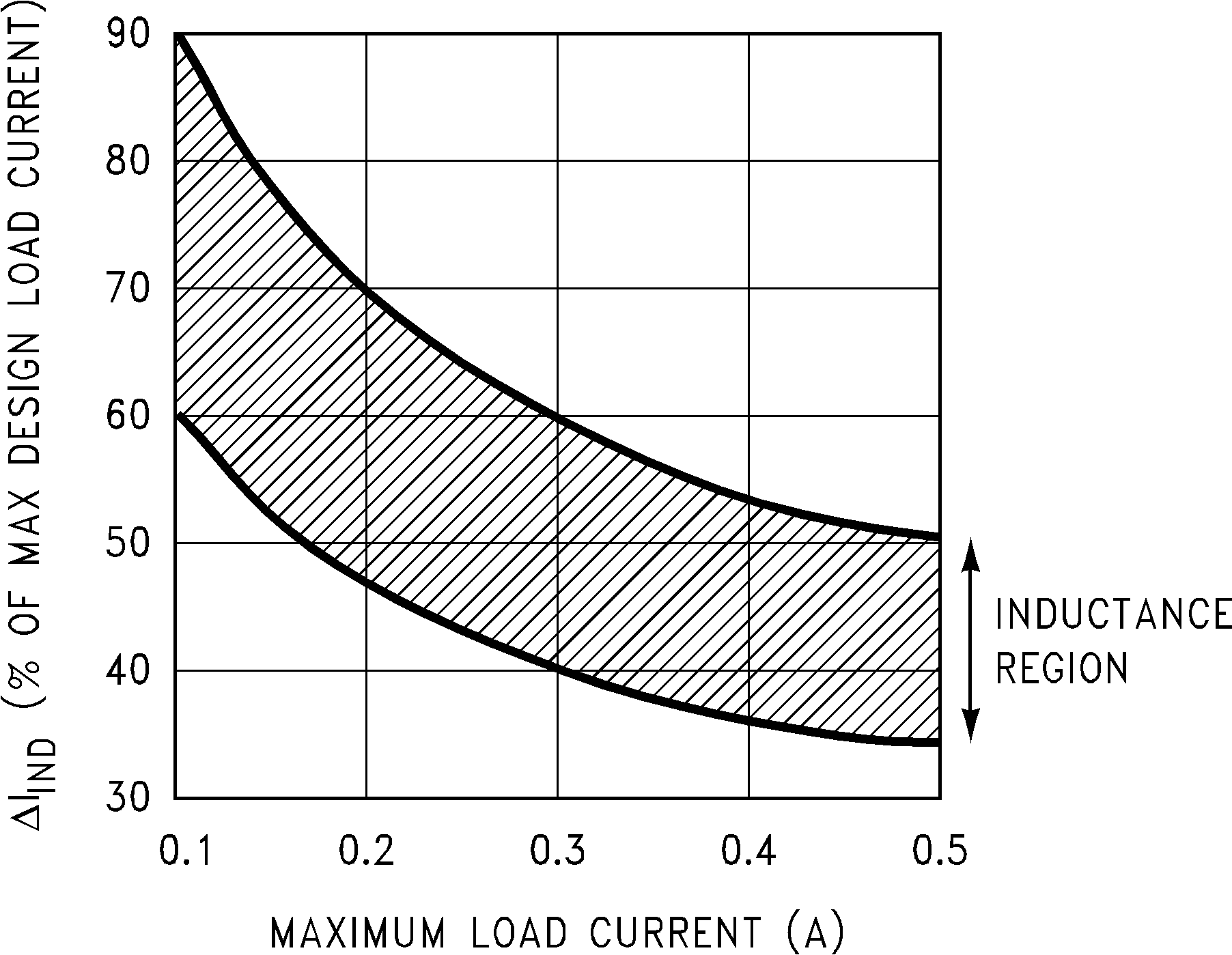

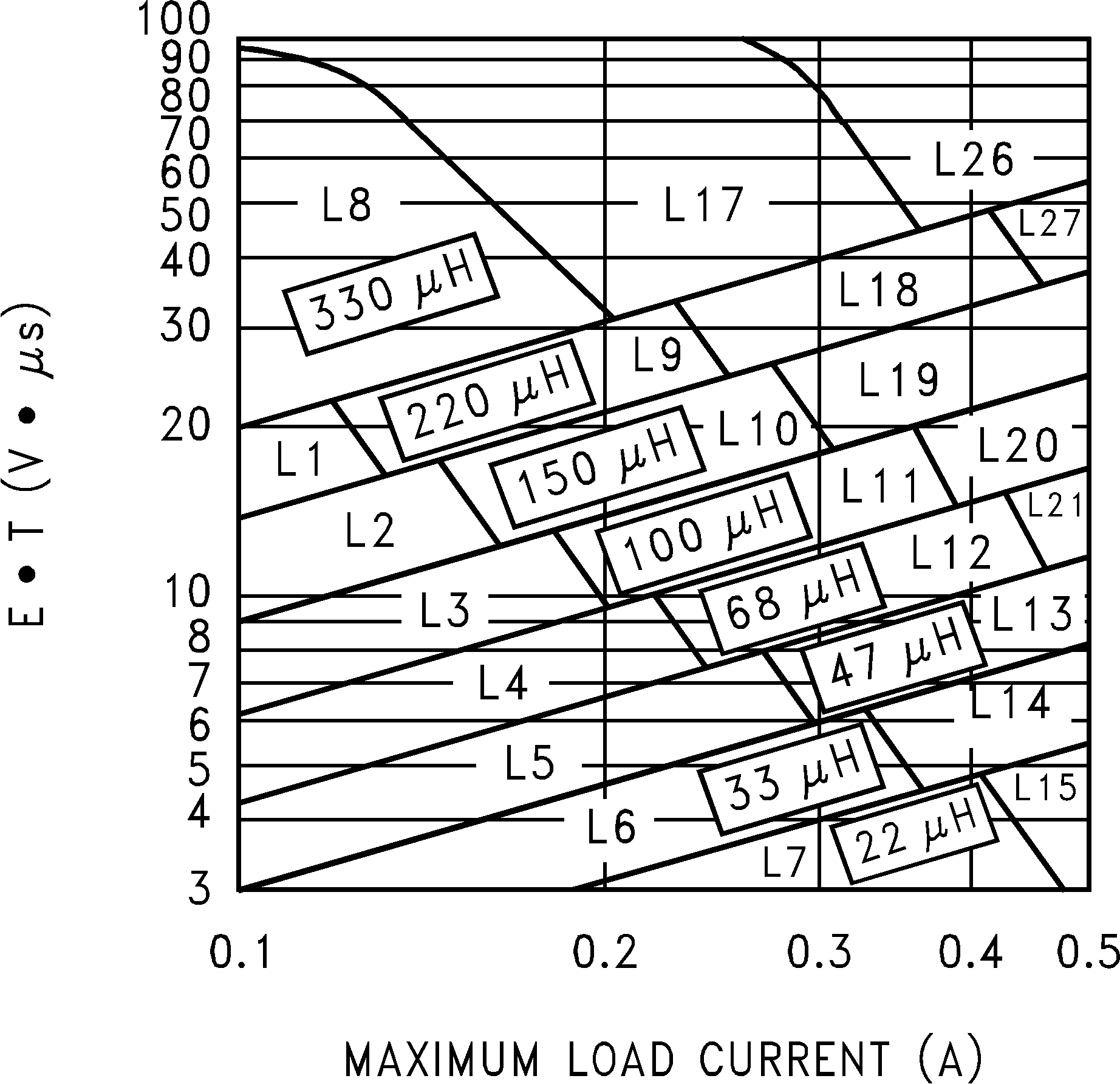

To simplify the inductor selection process, an inductor selection guide (nomograph) was designed (see Figure 9-5 through Figure 9-8). This guide assumes that the regulator is operating in the continuous mode, and selects an inductor that allows a peak-to-peak inductor ripple current to be a certain percentage of the maximum design load current. This peak-to-peak inductor ripple current percentage is not fixed, but is allowed to change as different design load currents are selected. (See Figure 9-4).

Figure 9-4 (ΔIIND) Peak-to-Peak Inductor Ripple Current (as a Percentage of the Load Current) versus Load Current

Figure 9-4 (ΔIIND) Peak-to-Peak Inductor Ripple Current (as a Percentage of the Load Current) versus Load CurrentBy allowing the percentage of inductor ripple current to increase for low load currents, the inductor value and size can be kept relatively low.

When operating in the continuous mode, the inductor current waveform ranges from a triangular to a sawtooth type of waveform (depending on the input voltage), with the average value of this current waveform equal to the DC output load current.

Inductors are available in different styles such as pot core, toroid, E-core, bobbin core, and so forth, as well as different core materials, such as ferrites and powdered iron. The least expensive, the bobbin, rod or stick core, consists of wire wrapped on a ferrite bobbin. This type of construction makes for a inexpensive inductor; however, because the magnetic flux is not completely contained within the core, it generates more Electro-Magnetic Interference (EMl). This magnetic flux can induce voltages into nearby printed-circuit traces, thus causing problems with both the switching regulator operation and nearby sensitive circuitry, and can give incorrect scope readings because of induced voltages in the scope probe (see Section 9.1.6).

The inductors listed in the selection chart include ferrite E-core construction for Schott ferrite bobbin core for Renco and Coilcraft, and powdered iron toroid for Pulse Engineering.

Exceeding the maximum current rating of the inductor can cause the inductor to overheat because of the copper wire losses, or the core can saturate. If the inductor begins to saturate, the inductance decreases rapidly and the inductor begins to look mainly resistive (the DC resistance of the winding). This can cause the switch current to rise very rapidly and force the switch into a cycle-by-cycle current limit, thus reducing the DC output load current. This can also result in overheating of the inductor and the LM2594. Different inductor types have different saturation characteristics, and this must be kept in mind when selecting an inductor.

The inductor manufacturers data sheets include current and energy limits to avoid inductor saturation.

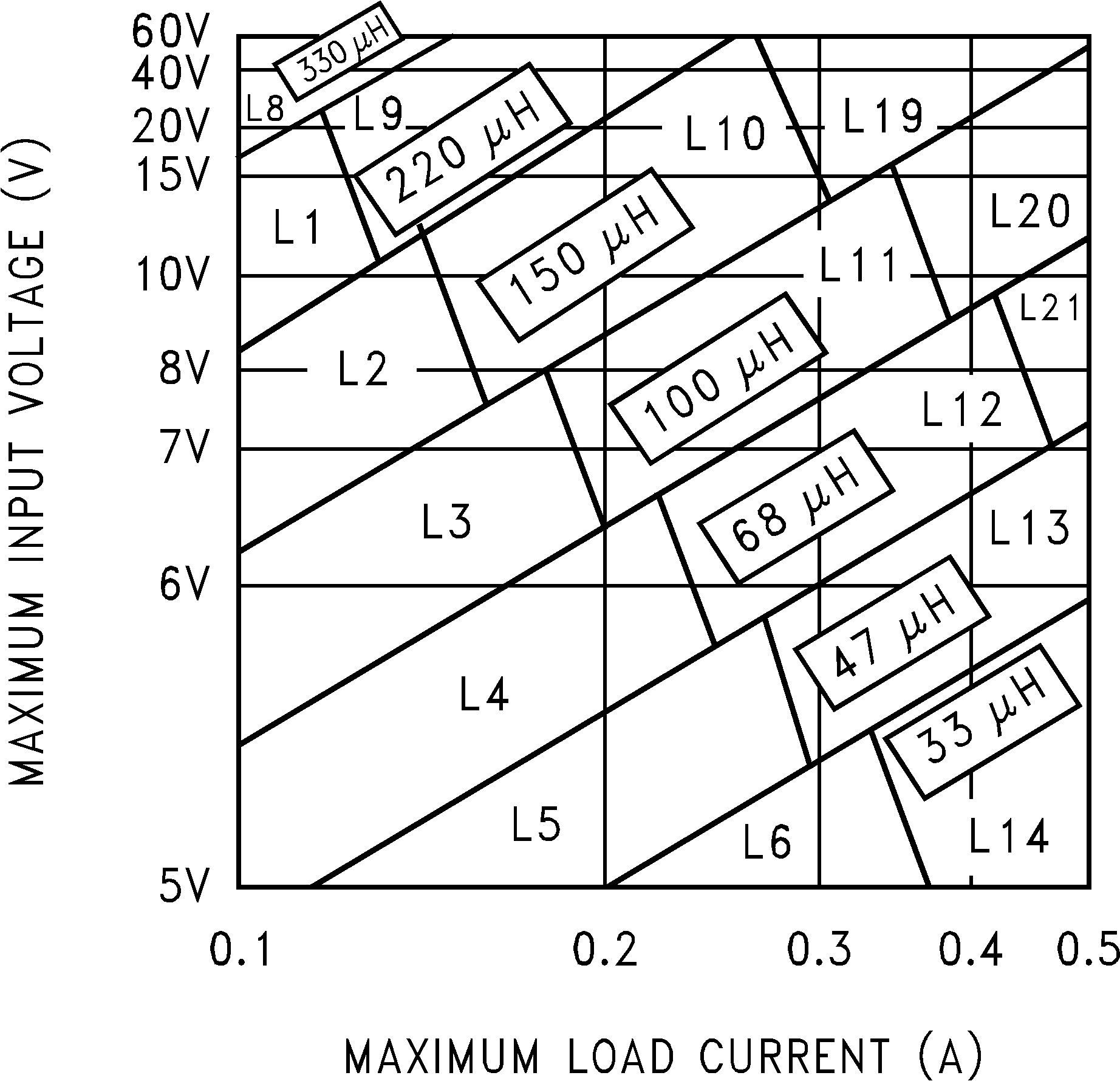

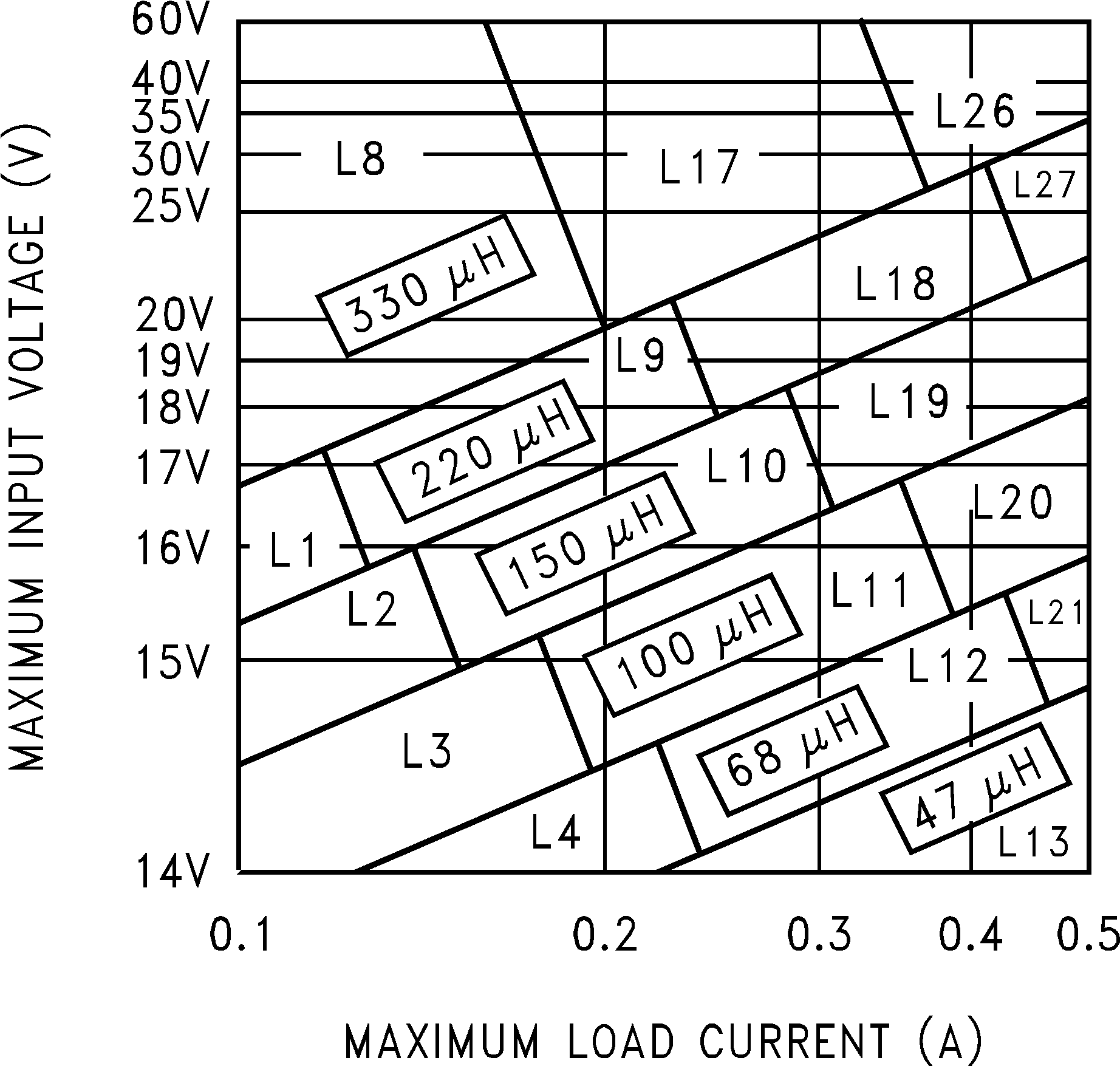

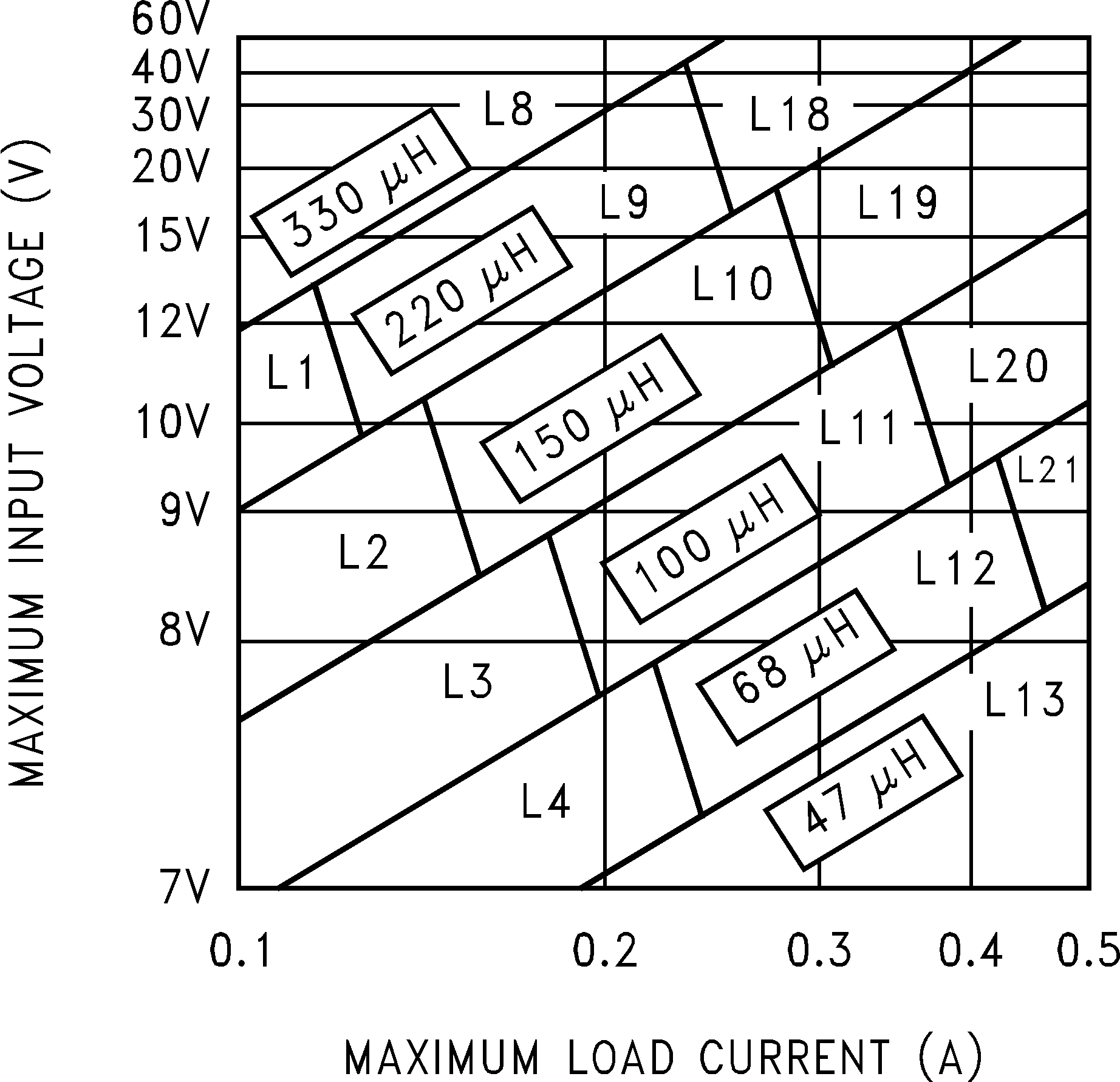

For continuous mode operation, see the inductor selection graphs in Figure 9-5 through Figure 9-8.

Figure 9-5 LM2594xx 3.3-V

Figure 9-5 LM2594xx 3.3-V Figure 9-7 LM2594xx 12-V

Figure 9-7 LM2594xx 12-V Figure 9-6 LM2594xx 5-V

Figure 9-6 LM2594xx 5-V Figure 9-8 LM2594xx Adjustable Voltage

Figure 9-8 LM2594xx Adjustable Voltage| INDUCTANCE (μH) | CURRENT (A) | SCHOTTKY | RENCO | PULSE ENGINEERING | COILCRAFT | ||||

|---|---|---|---|---|---|---|---|---|---|

| THROUGH HOLE | SURFACE MOUNT | THROUGH HOLE | SURFACE MOUNT | THROUGH HOLE | SURFACE MOUNT | SURFACE MOUNT | |||

| L1 | 220 | 0.18 | 67143910 | 67144280 | RL-5470-3 | RL1500-220 | PE-53801 | PE-53801-S | DO1608-224 |

| L2 | 150 | 0.21 | 67143920 | 67144290 | RL-5470-4 | RL1500-150 | PE-53802 | PE-53802-S | DO1608-154 |

| L3 | 100 | 0.26 | 67143930 | 67144300 | RL-5470-5 | RL1500-100 | PE-53803 | PE-53803-S | DO1608-104 |

| L4 | 68 | 0.32 | 67143940 | 67144310 | RL-1284-68 | RL1500-68 | PE-53804 | PE-53804-S | DO1608-68 |

| L5 | 47 | 0.37 | 67148310 | 67148420 | RL-1284-47 | RL1500-47 | PE-53805 | PE-53805-S | DO1608-473 |

| L6 | 33 | 0.44 | 67148320 | 67148430 | RL-1284-33 | RL1500-33 | PE-53806 | PE-53806-S | DO1608-333 |

| L7 | 22 | 0.60 | 67148330 | 67148440 | RL-1284-22 | RL1500-22 | PE-53807 | PE-53807-S | DO1608-223 |

| L8 | 330 | 0.26 | 67143950 | 67144320 | RL-5470-2 | RL1500-330 | PE-53808 | PE-53808-S | DO3308-334 |

| L9 | 220 | 0.32 | 67143960 | 67144330 | RL-5470-3 | RL1500-220 | PE-53809 | PE-53809-S | DO3308-224 |

| L10 | 150 | 0.39 | 67143970 | 67144340 | RL-5470-4 | RL1500-150 | PE-53810 | PE-53810-S | DO3308-154 |

| L11 | 100 | 0.48 | 67143980 | 67144350 | RL-5470-5 | RL1500-100 | PE-53811 | PE-53811-S | DO3308-104 |

| L12 | 68 | 0.58 | 67143990 | 67144360 | RL-5470-6 | RL1500-68 | PE-53812 | PE-53812-S | DO1608-683 |

| L13 | 47 | 0.70 | 67144000 | 67144380 | RL-5470-7 | RL1500-47 | PE-53813 | PE-53813-S | DO3308-473 |

| L14 | 33 | 0.83 | 67148340 | 67148450 | RL-1284-33 | RL1500-33 | PE-53814 | PE-53814-S | DO1608-333 |

| L15 | 22 | 0.99 | 67148350 | 67148460 | RL-1284-22 | RL1500-22 | PE-53815 | PE-53815-S | DO1608-223 |

| L16 | 15 | 1.24 | 67148360 | 67148470 | RL-1284-15 | RL1500-15 | PE-53816 | PE-53816-S | DO1608-153 |

| L17 | 330 | 0.42 | 67144030 | 67144410 | RL-5471-1 | RL1500-330 | PE-53817 | PE-53817-S | DO3316-334 |

| L18 | 220 | 0.55 | 67144040 | 67144420 | RL-5471-2 | RL1500-220 | PE-53818 | PE-53818-S | DO3316-224 |

| L19 | 150 | 0.66 | 67144050 | 67144430 | RL-5471-3 | RL1500-150 | PE-53819 | PE-53819-S | DO3316-154 |

| L20 | 100 | 0.82 | 67144060 | 67144440 | RL-5471-4 | RL1500-100 | PE-53820 | PE-53820-S | DO3316-104 |

| L21 | 68 | 0.99 | 67144070 | 67144450 | RL-5471-5 | RL1500-68 | PE-53821 | PE-53821-S | DDO3316-683 |

| L26 | 330 | 0.80 | 67144100 | 67144480 | RL-5471-1 | — | PE-53826 | PE-53826-S | — |

| L27 | 220 | 1.00 | 67144110 | 67144490 | RL-5471-2 | — | PE-53827 | PE-53827-S | — |