SWRU598A June 2022 – April 2024 AWR1243 , AWR1642 , AWR1843 , AWR2243 , AWR2944 , AWR6443 , AWR6843 , AWRL1432 , AWRL6432 , IWR6843

2.5 Step-5: Certification

The FuSa certification is the final step of proposed FuSa design life cycle. The final system topology along with all the essential safety collaterals of the blocks is now ready for the FuSa certification process. A qualified Functional Safety Expert (FSE) plays a vital role in building the FuSa compliant sensor system by following the FuSa certified system development process.

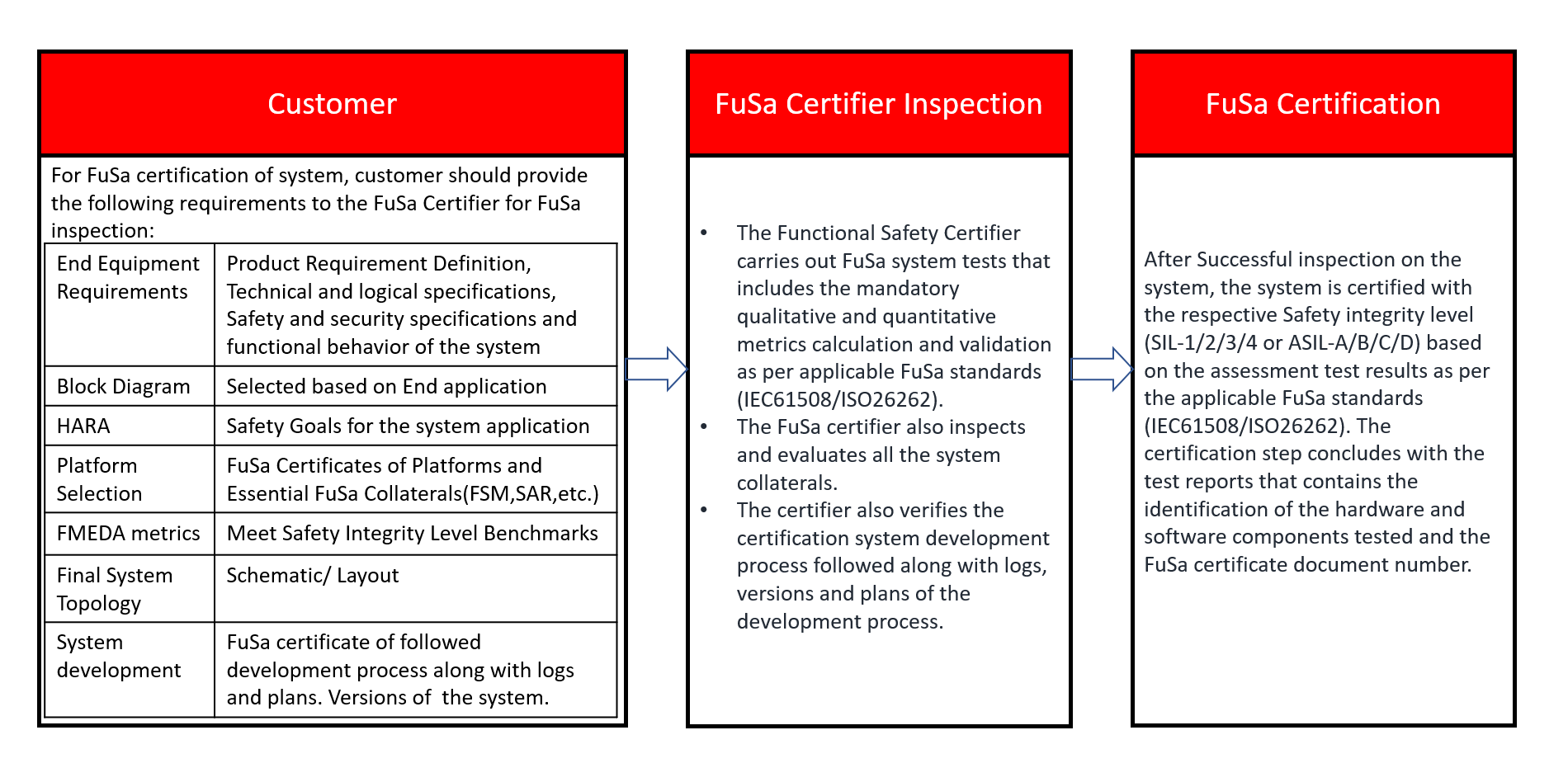

The adherence to safety goals as per applicable FuSa standards by the system will be assessed by the third-party certification bodies like Technischer Überwachungsverein (TÜV) for the FuSa compliance level certification. The essential collaterals, logs, versions, FuSa certificate of followed System development process(Hardware and Software) and safety plans of the system design ought to be shared with the FuSa certification body with evidences which are taken care by the system integrator's FSE. The FSE takes feedback from the certifier during the inspection for improving the safety of system until the targeted FuSa certification benchmarks are met. The certification body reviews the system documentation collaterals, verifies the system development process and evaluates the system design by performing FuSa system tests. After successful inspection by FuSa certifier, based on the assessment results, the system will be certified with respective safety integrity level as per FuSa standards and concludes with the report on certificate. Once the system is FuSa compliance certified, the sensor system is now ready to be used in Safety applications like Automotive and Industrial applications as per the FuSa certification safety integrity level. The following Figure 2-8 describes the flow of the certification step.

Figure 2-8 FuSa Certification step

flow

Figure 2-8 FuSa Certification step

flowFor ex., the FuSa certification of the corner radar system developed by the customer as per automotive FuSa standard ISO 26262 has to be certified by the Third party certifiers like TÜV. The essential collaterals of the system, versions, logs, followed system development process and safety plans of system must be readily available to share with certifier for FuSa compliance level certification. Similarly, for the FuSa certification of the Intelligent Robot sensing system of safer human presence detection as per industrial FuSa standard IEC 61508, the customer must provide the essential collaterals, versions, logs of system design, safety plans and the followed system development process to the certification body for assessing the system and certify safety integrity level(SIL-1/2/3/4) to the system.

- The role of TI or other companies whose component has also been used is in the system for safety is only to share the essential collaterals of that component which might support the customer. The customer possess the whole responsibility of the system design and its usage in safety applications.

- Sometimes as a feedback from the FuSa certifier, customer might be asked to add safety hooks to the system which might lead to hardware changes, not only software. After every update to the design at this stage, Design and Analysis flow must be repeated again.

Key Deliverables from the "Step-5: Certification" is the safety integrity level(ASIL-A/B/C/D or SIL-1/2/3/4) certification of the system's design from the FuSa certification body as per applicable FuSa standards. In this FuSa certification step, the FuSa certification body assesses the system by performing tests, evaluates all the collaterals and verifies system development process(logs, versions and plans). The FSE plays a crucial role by managing the system design process for FuSa certification of system. Once, the customer's system design is certified with safety integrity level compliance according to applicable FuSa standards, the FuSa certificate acts as license for system design usage in appropriate safety critical applications.