SNIS128D August 2002 – June 2014 LM89

UNLESS OTHERWISE NOTED, this document contains ADVANCE INFORMATION for pre-production products; subject to change without notice.

- 1 Features

- 2 Applications

- 3 Description

- 4 Remote Diode Temperature Sensor System Diagram

- 5 Revision History

- 6 Device Comparison Table

- 7 Pin Configuration And Functions

- 8 Specifications

-

9 Detailed Description

- 9.1 Overview

- 9.2 Functional Block Diagram

- 9.3

Feature Description

- 9.3.1 Conversion Sequence

- 9.3.2 The ALERT Output

- 9.3.3 T_CRIT_A Output And T_CRIT Limit

- 9.3.4 Smbus Interface

- 9.3.5 Temperature Data Format

- 9.3.6 Open-Drain Outputs

- 9.3.7 Diode Fault Detection

- 9.3.8 Communicating With The LM89

- 9.3.9 Serial Interface Reset

- 9.3.10 Digital Filter

- 9.3.11 Fault Queue

- 9.3.12 One-Shot Register

- 9.4 Device Functional Modes

- 9.5 Programming

- 9.6

Register Maps

- 9.6.1 Command Register

- 9.6.2 Local And Remote Temperature Registers (LT, RTHB, RTLB)

- 9.6.3 Status Register (SR)

- 9.6.4 Configuration Register

- 9.6.5 Conversion Rate Register

- 9.6.6 Local And Remote High Setpoint Registers (LHS, RHSHB, And RHSLB)

- 9.6.7 Local And Remote Low Setpoint Registers (LLS, RLSHB, And RLSLB)

- 9.6.8 Remote Temperature Offset Registers (RTOHB And RTOLB)

- 9.6.9 Local And Remote T_crit Registers (RCS And LCS)

- 9.6.10 T_CRIT Hysteresis Register (TH)

- 9.6.11 Filter And Alert Configure Register

- 9.6.12 Manufacturers Id Register

- 9.6.13 Die Revision Code Register

- 10Application and Implementation

- 11Power Supply Recommendations

- 12Layout

- 13Device and Documentation Support

- 14Mechanical, Packaging, and Orderable Information

10 Application and Implementation

10.1 Application Information

The LM89 can be applied easily in the same way as other integrated-circuit temperature sensors, and its remote diode sensing capability allows it to be used in new ways as well. It can be soldered to a printed circuit board, and because the path of best thermal conductivity is between the die and the pins, its temperature will effectively be that of the printed circuit board lands and traces soldered to the LM89's pins. This presumes that the ambient air temperature is almost the same as the surface temperature of the printed circuit board; if the air temperature is much higher or lower than the surface temperature, the actual temperature of the LM89 die will be at an intermediate temperature between the surface and air temperatures. Again, the primary thermal conduction path is through the leads, so the circuit board temperature will contribute to the die temperature much more strongly than will the air temperature.

To measure temperature external to the LM89's die, use a remote diode. This diode can be located on the die of a target IC, allowing measurement of the IC's temperature, independent of the LM89's temperature.

10.2 Typical Application

The LM89 has been optimized to measure the remote thermal diode of a 0.13 micron Pentium 4, a Mobile Pentium 4 Processor-M processor or other embedded thermal diodes that have similar characteristics. A discrete diode can also be used to sense the temperature of external objects or ambient air. Remember that a discrete diode's temperature will be affected, and often dominated, by the temperature of its leads. Most silicon diodes do not lend themselves well to this application. It is recommended that a MMBT3904 transistor base emitter junction be used with the collector tied to the base (diode-connected).

An LM89 with a diode-connected MMBT3904 will have a typical -1°C offset.

10.2.1 Design Requirements

10.2.1.1 Diode Nonideality

10.2.1.1.1 Diode Nonideality Factor Effect On Accuracy

When a transistor is connected as a diode, the following relationship holds for variables VBE, T and If:

where

where

- q = 1.6×10−19 Coulombs (the electron charge),

- T = Absolute Temperature in Kelvin

- k = 1.38×10−23joules/K (Boltzmann's constant),

- η is the nonideality factor of the process the diode is manufactured on,

- IS = Saturation Current and is process dependent,

- If= Forward Current through the base emitter junction

- VBE = Base Emitter Voltage drop

In the active region, the -1 term is negligible and may be eliminated, yielding the following equation

In the above equation, η and IS are dependant upon the process that was used in the fabrication of the particular diode. By forcing two currents with a very controlled ratio (N) and measuring the resulting voltage difference, it is possible to eliminate the IS term. Solving for the forward voltage difference yields the relationship:

The voltage seen by the LM89 also includes the IFRS voltage drop of the series resistance. The nonideality factor, η, is the only other parameter not accounted for and depends on the diode that is used for measurement. Since ΔVBE is proportional to both η and T, the variations in η cannot be distinguished from variations in temperature. Since the nonideality factor is not controlled by the temperature sensor, it will directly add to the inaccuracy of the sensor. For the Pentium 4 and Mobile Pentium Processor-M Intel specifies a ±0.1% variation in η from part to part. As an example, assume a temperature sensor has an accuracy specification of ±1°C at room temperature of 25 °C and the process used to manufacture the diode has a nonideality variation of ±0.1%. The resulting accuracy of the temperature sensor at room temperature will be:

The additional inaccuracy in the temperature measurement caused by η, can be eliminated if each temperature sensor is calibrated with the remote diode that it will be paired with.

| Processor Family | η, nonideality | ||

|---|---|---|---|

| MIN | TYP | MAX | |

| Pentium III CPUID 67h | 1 | 1.0065 | 1.0125 |

| Pentium III CPUID 68h/PGA370Socket/Celeron | 1.0057 | 1.008 | 1.0125 |

| Pentium 4, 423 pin | 0.9933 | 1.0045 | 1.0368 |

| Pentium 4, 478 pin | 0.9933 | 1.0045 | 1.0368 |

| 0.13 micron, Pentium 4 | 1.0011 | 1.0021 | 1.0030 |

| MMBT3904 | 1.003 | ||

| AMD Athlon MP model 6 | 1.002 | 1.008 | 1.016 |

10.2.2 Detailed Design Procedure

10.2.2.1 Compensating For Diode Nonideality

In order to compensate for the errors introduced by nonideality, the temperature sensor is calibrated for a particular processor. The LM89 is calibrated for the nonideality of a 0.13 micron, Mobile Pentium 4, 1.0021. When a temperature sensor calibrated for a particular processor type is used with a different processor type or a given processor type has a nonideality that strays from the typical, errors are introduced.

Temperature errors associated with nonideality may be reduced in a specific temperature range of concern through use of the offset registers (11h and 12h).

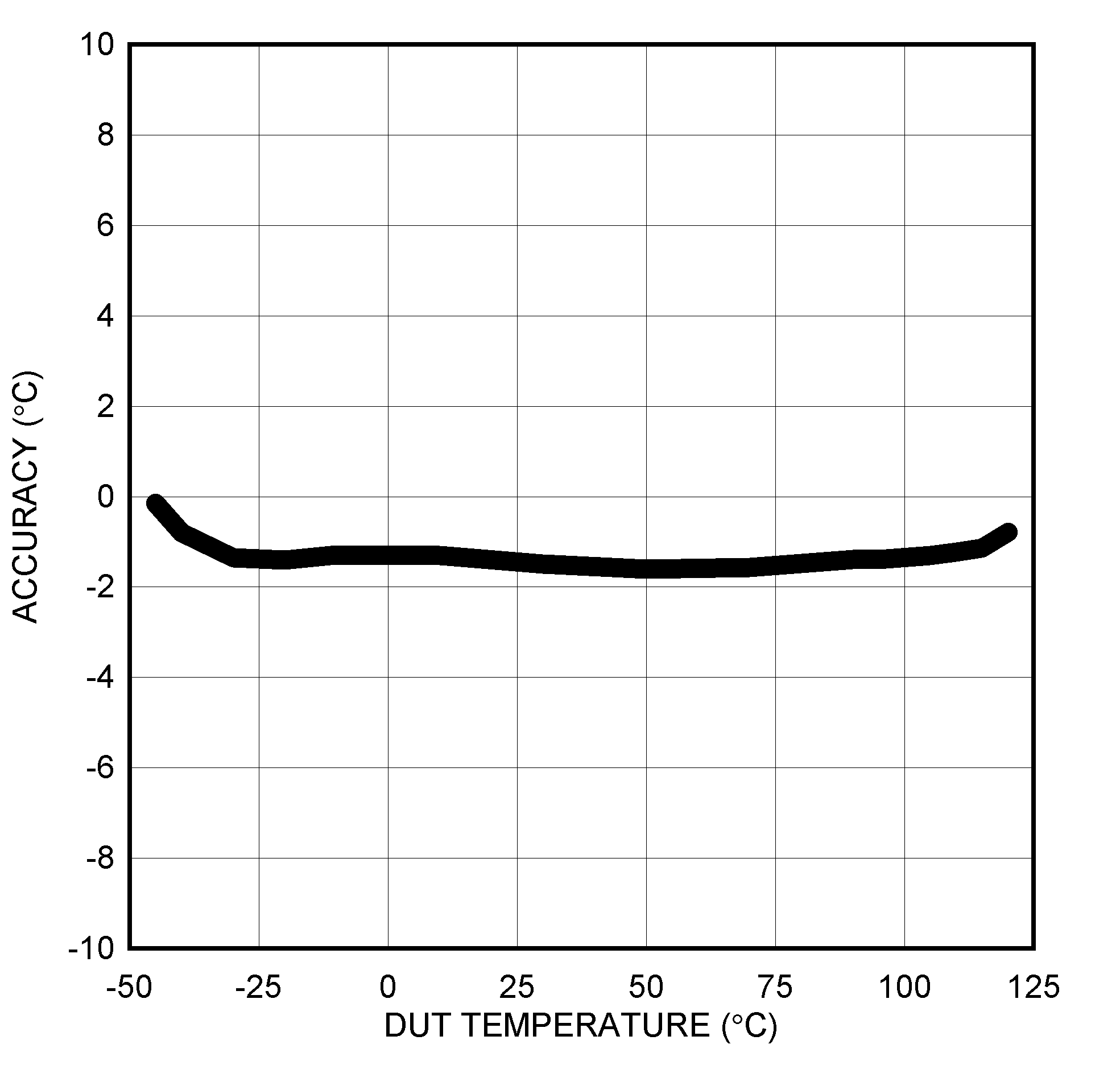

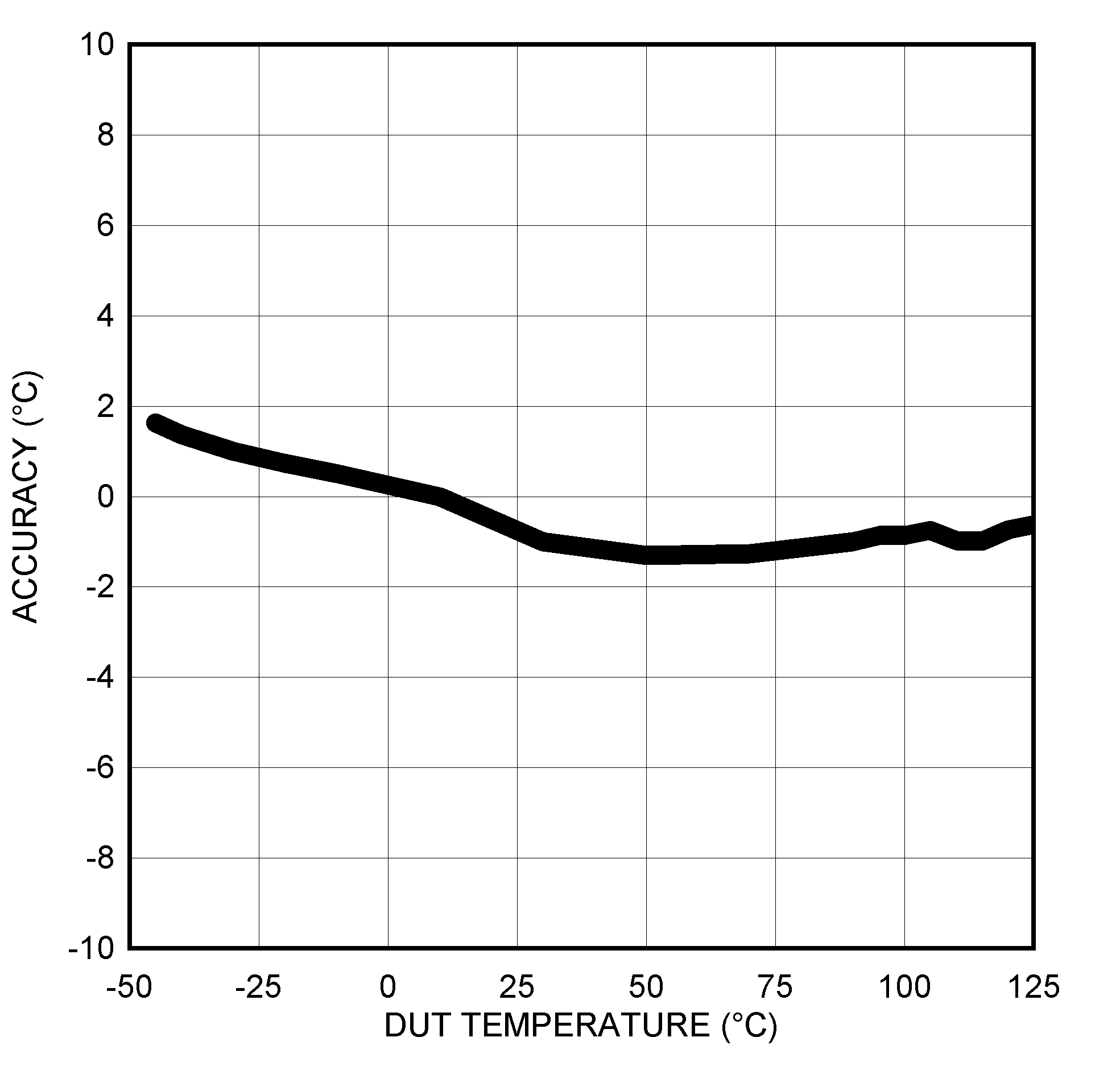

10.2.3 Application Curves

| LM89 is connected to diode-connected MMBT3904. | ||

| 2N3904 and LM89 junction temperatures are equivalent during test. |

10.3 Do's and Don'ts

Noise coupling into the digital lines greater than 400mVp-p (typical hysteresis) and undershoot less than 500mV below GND, may prevent successful SMBus communication with the LM89. SMBus no acknowledge is the most common symptom, causing unnecessary traffic on the bus. Although the SMBus maximum frequency of communication is rather low (100kHz max), care still needs to be taken to ensure proper termination within a system with multiple parts on the bus and long printed circuit board traces. An RC lowpass filter with a 3db corner frequency of about 40MHz is included on the LM89's SMBCLK input. Additional resistance can be added in series with the SMBData and SMBCLK lines to further help filter noise and ringing. Minimize noise coupling by keeping digital traces out of switching power supply areas as well as ensuring that digital lines containing high speed data communications cross at right angles to the SMBData and SMBCLK lines.