TIDUES0E June 2019 – April 2024 TMS320F28P550SJ , TMS320F28P559SJ-Q1

- 1

- Description

- Resources

- Features

- Applications

- 6

- 1System Description

- 2System Overview

- 3Circuit Description

- 4Hardware, Software, Testing Requirements, and Test Results

- 5Design Files

- 6Related Documentation

- 7Terminology

- 8About the Author

- 9Revision History

4.1.2.1 Getting Started With Software

- Install Code Composer Studio (CSS)

- Download and install C2000WARE-DIGITALPOWER-SDK

- Open CCS, go to project → Import project and

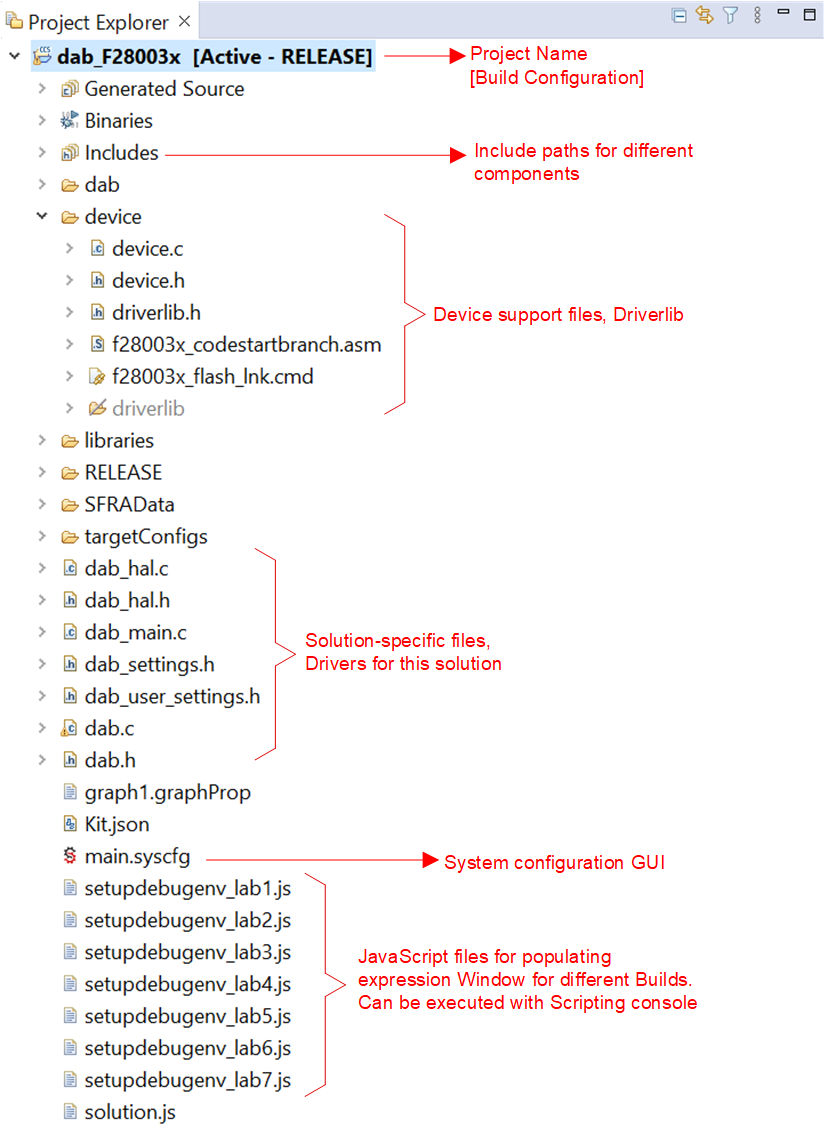

browse to the folder

C:\ti\c2000\C2000Ware_DigitalPower_SDK_5_02_00_00\solutions\tida_010054\f28003x\ccs. The DAB project is listed. Complete the steps to import the project. (For newer versions of C2000Ware the install path can differ) - The code is designed for the F28003x control card.Figure 4-1 shows the loaded project explorer view. Open main.syscfg in the Project Explorer window, choose lab and then compile, then program the device.

- Once loaded, enable real-time mode and run the code.

- To add the variables in the watch or expressions window, click View → Scripting Console to open the scripting console dialog box. On the upper right corner of this console, click on Open and then browse to the “setupdebugenv_lab1.js” script file located inside the project folder. This populates the watch window with appropriate variables needed to debug the system.

- Select the Continuous Refresh button on the watch window to enable continuous updates of values from the controller. Figure 4-13 illustrates the watch window.

Figure 4-1 Project Explorer View

Figure 4-1 Project Explorer View