SSZTBA2 may 2016 AM5706 , AM5708 , AM5716 , AM5718 , AM5726 , AM5728 , AM5746 , AM5748

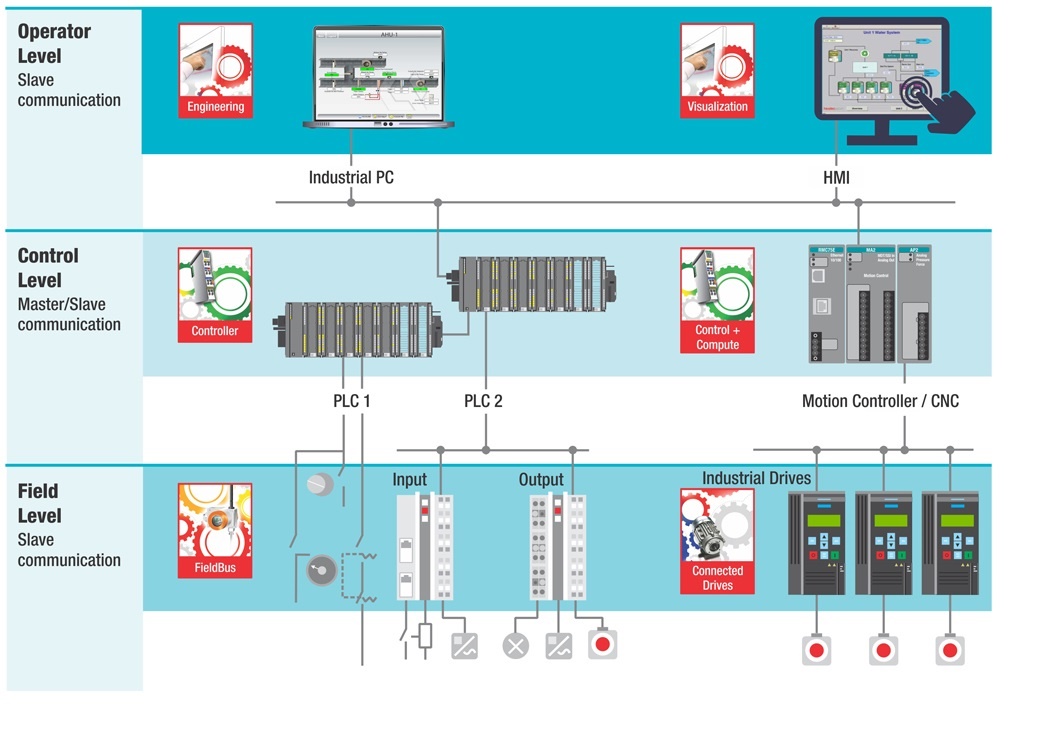

Factory automation systems designed for Industry 4.0 typically contain three main levels of equipment that drive real-time communications and control:

- The field level where I/O modules, actuators, and drives are engaged in the physical operation of the factory,

- The control level where PLCs or CNCs collect information from and issue commands to the field level,

- The operator level where HMI devices communicate information with operators and where operators can issue commands.

Each of these levels has its own set of taxing design challenges that require optimized hardware and software solutions. The challenges related to the control level are particularly difficult to meet.

In addition to the challenges with all industrial automation designs (power consumption, long supply lifetimes, reliability requirements), designers of equipment for the control level face certain challenges that arise from the increasing number of nodes that one controller can support. A larger number of supported nodes means that fewer controllers are needed in the overall factory solution to create a less expensive automation solution or that more nodes can be supported in the factory for higher levels of automation. However, with the increase in the number of supported nodes, the processor performance must also increase while still consuming low enough power as to not force an increase in the size of enclosure. Additionally, most PLCs are designed to not require a fan so power dissipation is a key design aspect.

With PLCs and CNCs concurrently controlling a high number of nodes or functions in the factory, the real-time aspects of their operation is critical. Two components are needed for a solution to the tight timing requirements: real time operating systems and flexible time-aware peripherals for industrial communications. Real Time Operating Systems (RTOSes) are used in these equipment for their determinism and ability to control latency in order to meet the critical timing needs. Commercial RTOSes have been widely used in industrial control applications for many years, and there is also growing interest in RT Linux® solutions which have all the advantages of the large open source community around Linux while adding the time-awareness and determinism required for industrial automation applications.

For the communications peripherals portion of the real-time solution, the main need is to support industrial fieldbus protocols in a way that allows for low latencies and reduced protocol cycle times even when there is the demand for an increased number of nodes. It becomes an even more complex challenge when it is considered that that multiple fieldbus standards must be supported from a single design. Multi-protocol support is necessary in order to make the end products compatible with the multiple standards that may be found already in use in a factory- such as EtherCAT, PROFINET, Ethernet/IP, and more. Support for multiple protocols is complex to solve with hardware (ASICs) as different board designs will be needed for each supported fieldbus since each protocol may require its own specific ASIC. It is a smaller challenge if a programmable approach is taken where a software or firmware change is all that is needed to change the fieldbus protocol.

To facilitate this real-time communication solution, controllers need a large number of peripheral interfaces since they communicate on multiple levels- with the fieldbus networks in the factory, with the backplane for the connected I/Os, actuators, drives, or with other controllers, and with servers for data collection for factory diagnostic concerns using protocols such as OPC UA. All of this together drives a need to have a large number of peripheral interfaces, especially Ethernet, and to also have a flexible, programmable communications solution.

Image: Programmable Logic Controller and I/O Cards

The TMDSIDK574 industrial development kit (IDK) for Sitara™ AM574x processors is now available to evaluate control level factory automation solutions. The AM574x dual-core Arm® processor is well-suited to industrial applications due to its support for industrial temperature ranges, ability to achieve long lifetimes of up to 100,000 power-on hours, real-time software support, ECC for external DDR memory and extensive peripheral set, such as the dual PRU-ICSS (Processor Real-Time Unit-Industrial Communication Subsystem) for programmable industrial communications. The TMDSIDK574 provides four ports for Ethernet, either two from the Gigabit switch + two from the PRU-ICSS (default configuration) or four from the PRU-ICSS. The TMDSIDK574 can be used to evaluate TI’s newly released solutions for industrial fieldbus protocols on AM57x which are delivered through PRU-ICSS-INDUSTRIAL-SW on top of Processor-SDK-RTOS. Additionally, TMDSIDK574 can run the Processor-SDK-Linux-RT package which provides optimized RT Preempt patches on top of TI’s mainline Linux kernel for the development of real-time industrial automation applications.