SLVAFB4 July 2022 TPS62902-Q1 , TPS62903 , TPS62903-Q1

1.2 Output Current Calculations

The average inductor current is affected in this topology. In the buck configuration, the average inductor current equals the average output current because the inductor always supplies current to the load during both the on and off times of the control MOSFET. However, in the inverting buck - boost configuration, the load is supplied with current only from the output capacitor and is completely disconnected from the inductor during the on time of the control MOSFET. During the off time, the inductor connects to both the output capacitor and the load (see Figure 1-3). Knowing that the off time is 1-D of the switching period, then the average inductor current is:

The duty cycle for the typical buck converter is simply VOUT / VIN but the duty cycle for an inverting buck - boost converter becomes:

The efficiency term in Equation 2 adjusts the equations in this section for power conversion losses and yields a more accurate maximum output current result. Where VOUT is a negative value. The peak to peak inductor ripple current is calculated as:

Where,

∆IL (A): Peak to peak inductor ripple current

D: Duty cycle

η: Efficiency

fS (MHz): Switching frequency

L (µH): Inductance

VIN (V): Input voltage with respect to ground, instead of IC ground or -VOUT.

Finally, the maximum inductor current becomes:

For an output voltage of –3.3 V, 2.5 MHz switching frequency, 1µH inductor, and an input voltage of 12 V, the following calculations produce the maximum allowable output current that can be delivered based on the 4A minimum current limit (ILIM) of TPS62903. The efficiency term is estimated at 70%.

Rearranging Equation 4 and setting IL(max) equal to the minimum value of ILIM, as specified in the data sheet, gives:

This result is then used in Equation 1 to calculate the maximum achievable output current:

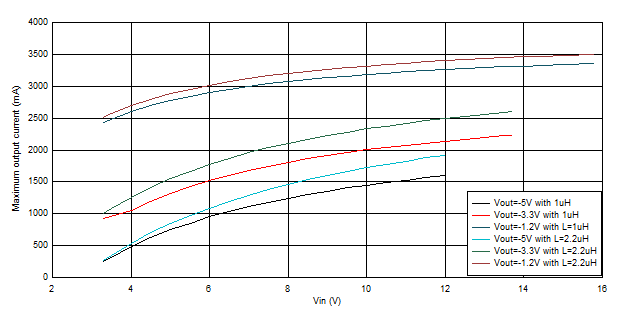

Increasing the inductance and/or input voltage allows higher output current in the inverting buck - boost topology. The maximum output current for the TPS62903 in the inverting buck - boost topology are frequently lower than 3A due to the fact that the average inductor current is higher than that of a typical buck. The output current for three output voltages (-1.2 V, -3.3 V, -5 V) with two inductors (1 µH, 2.2 µH) at FSW=2.5 MHz and different input voltages are displayed in Figure 1-4.

Figure 1-4 Maximum Output Current vs. Input Voltage

Figure 1-4 Maximum Output Current vs. Input Voltage