SNAS747 June 2017 ADC081S101-MIL

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Typical Characteristics

- 8 Detailed Description

- 9 Applications Information

- 10Power Supply Recommendations

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

8 Detailed Description

8.1 Overview

The ADC081S101-MIL is a successive-approximation analog-to-digital converter designed around a charge-redistribution digital-to-analog converter core. Simplified schematics of the ADC081S101-MIL in both track and hold operation are shown in Figure 17 and Figure 18, respectively. In Figure 17, the device is in track mode: switch SW1 connects the sampling capacitor to the input, and SW2 balances the comparator inputs. The device is in this state until CS is brought low, at which point the device moves to hold mode.

8.2 Functional Block Diagram

8.3 Feature Description

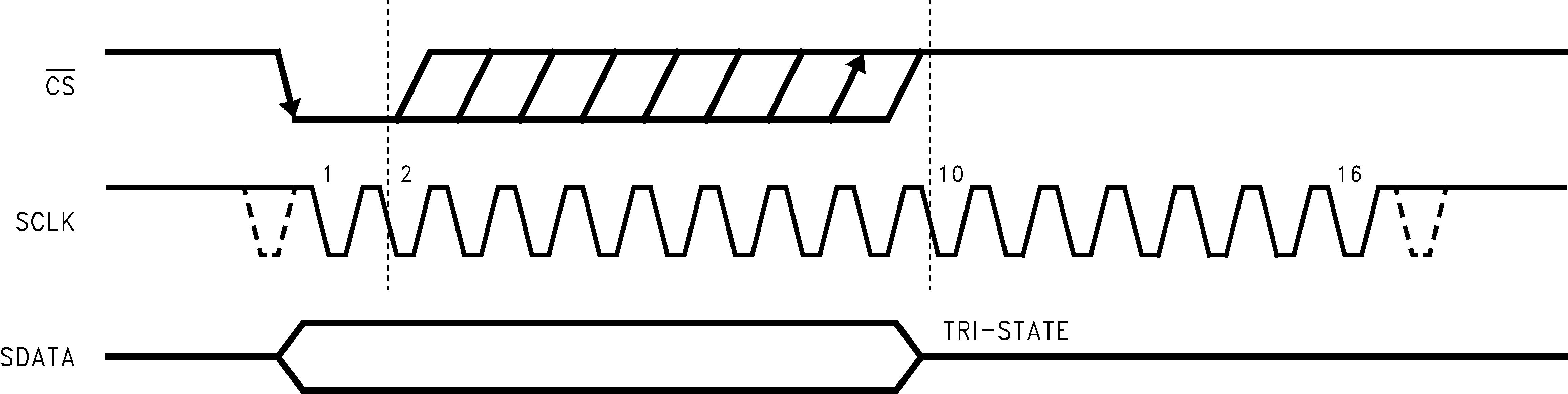

The serial interface timing diagram for the ADC is shown in Figure 2. CS is chip select, which initiates conversions on the ADC and frames the serial data transfers. SCLK (serial clock) controls both the conversion process and the timing of serial data. SDATA is the serial data out pin, where a conversion result is found as a serial data stream.

Basic operation of the ADC begins with CS going low, which initiates a conversion process and data transfer. Subsequent rising and falling edges of SCLK will be labeled with reference to the falling edge of CS; for example, "the third falling edge of SCLK" shall refer to the third falling edge of SCLK after CS goes low.

At the fall of CS, the SDATA pin comes out of TRI-STATE, and the converter moves from track mode to hold mode. The input signal is sampled and held for conversion on the falling edge of CS. The converter moves from hold mode to track mode on the 13th rising edge of SCLK (see Figure 2). It is at this point that the interval for the TACQ specification begins. At least 350ns must pass between the 13th rising edge of SCLK and the next falling edge of CS. The SDATA pin will be placed back into TRI-STATE after the 16th falling edge of SCLK, or at the rising edge of CS, whichever occurs first. After a conversion is completed, the quiet time tQUIET must be satisfied before bringing CS low again to begin another conversion.

Sixteen SCLK cycles are required to read a complete sample from the ADC. The sample bits (including leading or trailing zeroes) are clocked out on falling edges of SCLK, and are intended to be clocked in by a receiver on subsequent falling edges of SCLK. The ADC will produce three leading zero bits on SDATA, followed by eight data bits, most significant first. After the data bits, the ADC will clock out four trailing zeros.

If CS goes low before the rising edge of SCLK, an additional (fourth) zero bit may be captured by the next falling edge of SCLK.

8.3.1 Determining Throughput

Throughput depends on the frequency of SCLK and how much time is allowed to elapse between the end of one conversion and the start of another. At the maximum specified SCLK frequency, the maximum ensured throughput is obtained by using a 20 SCLK frame. As shown in Figure 2, the minimum allowed time between CS falling edges is determined by 1) 12.5 SCLKs for Hold mode, 2) the larger of two quantities: either the minimum required time for Track mode (tACQ) or 2.5 SCLKs to finish reading the result and 3) 0, 1/2 or 1 SCLK padding to ensure an even number of SCLK cycles so there is a falling SCLK edge when CS next falls. For example, at the fastest rate for this family of parts, SCLK is 20MHz and 2.5 SCLKs are 125ns, so the minimum time between CS falling edges is calculated by:

(12.5 SCLKs + tACQ + 1/2 SCLK) which corresponds to a maximum throughput of 1MSPS. At the slowest rate for this family, SCLK is 1MHz. Using a 20-cycle conversion frame as shown in Figure 2 yields a 20μs time between CS falling edges for a throughput of 50KSPS.

It is possible, however, to use fewer than 20 clock cycles provided the timing parameters are met. With a 1MHz SCLK, there are 2500ns in 2.5 SCLK cycles, which is greater than tACQ. After the last data bit has come out, the clock will need one full cycle to return to a falling edge. Thus the total time between falling edges of CS is 12.5*1μs +2.5*1μs +1*1μs=16μs which is a throughput of 62.5KSPS.

8.4 Device Functional Modes

Figure 18 shows the device in hold mode: switch SW1 connects the sampling capacitor to ground, maintaining the sampled voltage, and switch SW2 unbalances the comparator. The control logic then instructs the charge-redistribution DAC to add or subtract fixed amounts of charge from the sampling capacitor until the comparator is balanced. When the comparator is balanced, the digital word supplied to the DAC is the digital representation of the analog input voltage. The device moves from hold mode to track mode on the 13th rising edge of SCLK.

Figure 17. ADC081S101-MIL In Track Mode

Figure 17. ADC081S101-MIL In Track Mode

Figure 18. ADC081S101-MIL In Hold Mode

Figure 18. ADC081S101-MIL In Hold Mode

8.4.1 ADC081S101-MIL Transfer Function

The output format of the ADC is straight binary. Code transitions occur midway between successive integer LSB values. The LSB width for the ADC is VA/256. The ideal transfer characteristic is shown in Figure 19. The transition from an output code of 0000 0000 to a code of 0000 0001 is at 1/2 LSB, or a voltage of VA/512. Other code transitions occur at steps of one LSB.

Figure 19. Ideal Transfer Characteristic

Figure 19. Ideal Transfer Characteristic

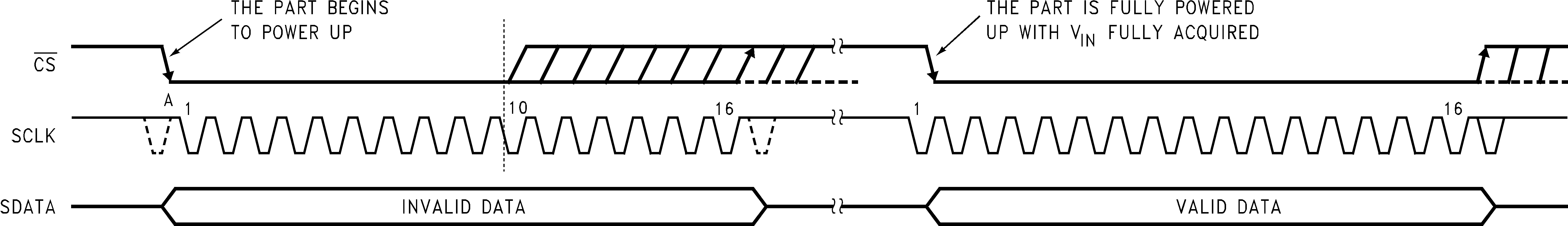

8.4.2 Modes Of Operation

The ADC has two possible modes of operation: normal mode, and shutdown mode. The ADC enters normal mode (and a conversion process is begun) when CS is pulled low. The device will enter shutdown mode if CS is pulled high before the tenth falling edge of SCLK after CS is pulled low, or will stay in normal mode if CS remains low. Once in shutdown mode, the device will stay there until CS is brought low again. By varying the ratio of time spent in the normal and shutdown modes, a system may trade-off throughput for power consumption, with a sample rate as low as zero.

8.4.2.1 Normal Mode

The fastest possible throughput is obtained by leaving the ADC in normal mode at all times, so there are no power-up delays. To keep the device in normal mode continuously, CS must be kept low until after the 10th falling edge of SCLK after the start of a conversion (remember that a conversion is initiated by bringing CS low).

If CS is brought high after the 10th falling edge, but before the 16th falling edge, the device will remain in normal mode, but the current conversion will be aborted, and SDATA will return to TRI-STATE (truncating the output word).

Sixteen SCLK cycles are required to read all of a conversion word from the device. After sixteen SCLK cycles have elapsed, CS may be idled either high or low until the next conversion. If CS is idled low, it must be brought high again before the start of the next conversion, which begins when CS is again brought low.

After sixteen SCLK cycles, SDATA returns to TRI-STATE. Another conversion may be started, after tQUIET has elapsed, by bringing CS low again.

8.4.2.2 Shutdown Mode

Shutdown mode is appropriate for applications that either do not sample continuously, or it is acceptable to trade throughput for power consumption. When the ADC is in shutdown mode, all of the analog circuitry is turned off.

To enter shutdown mode, a conversion must be interrupted by bringing CS back high anytime between the second and tenth falling edges of SCLK, as shown in Figure 20. Once CS has been brought high in this manner, the device will enter shutdown mode; the current conversion will be aborted and SDATA will enter TRI-STATE. If CS is brought high before the second falling edge of SCLK, the device will not change mode; this is to avoid accidentally changing mode as a result of noise on the CS line.

Figure 20. Entering Shutdown Mode

Figure 20. Entering Shutdown Mode

Figure 21. Entering Normal Mode

Figure 21. Entering Normal Mode

To exit shutdown mode, bring CS back low. Upon bringing CS low, the ADC will begin powering up (power-up time is specified in the Timing Requirements). This power-up delay results in the first conversion result being unusable. The second conversion performed after power-up, however, is valid, as shown in Figure 21.

If CS is brought back high before the 10th falling edge of SCLK, the device will return to shutdown mode. This is done to avoid accidentally entering normal mode as a result of noise on the CS line. To exit shutdown mode and remain in normal mode, CS must be kept low until after the 10th falling edge of SCLK. The ADC will be fully powered-up after 16 SCLK cycles.