SLUAA45 April 2020 BQ27Z561

-

End of Discharge SOC Jump Elimination

- Trademarks

- 1 Introduction

- 2 Improve Battery Modeling

- 3 Optimize Gauge Configurations

- 4 Achieve Successful Ra Table, Qmax and DOD0 Learning

- 5 References

1 Introduction

Battery fuel gauge is used to calculate the remaining capacity and full-charged capacity under any given load. It can tell the host side when the battery is going to be empty or full, what state of the battery right now, how much life time has left. This information will help the host side to do smarter power management for the whole system and also ensure safe charge/discharge. An accurate gauge is critical for the longer battery runtime and life span.

Impedance Track technology is a fuel-gauging algorithm developed by Texas Instruments. What makes it unique and more accurate than other solutions is the self-learning mechanism. IT algorithm continually measures and updates battery impedance and full chemical capacity. IT-based gauge can maintain its accuracy even as the battery ages. However, if the gauge was improperly configured, the gauge may perform badly in some applications. A possible issue encountering is the SOC jump issue.

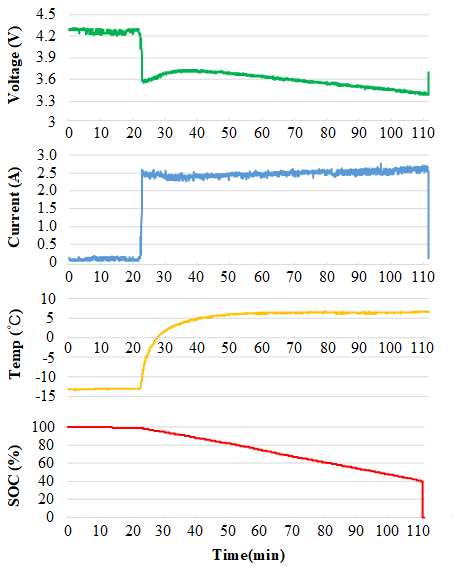

Figure 1(a) describes a low temperature discharge test of the portable device using TI gauge BQ27Z561-R1. There is a significant SOC drop from 40% to 0% that causing the device abruptly shut down. Essentially, SOC jump issue is an overestimation issue. Due to overestimation, the gauge ‘thinks’ there is still 40% of capacity left before the voltage reaches Termination Voltage (EDV). But gauge is forced to report SOC=0% once the voltage hits the EDV, causing a 40% drop of reported SOC at the EDV.

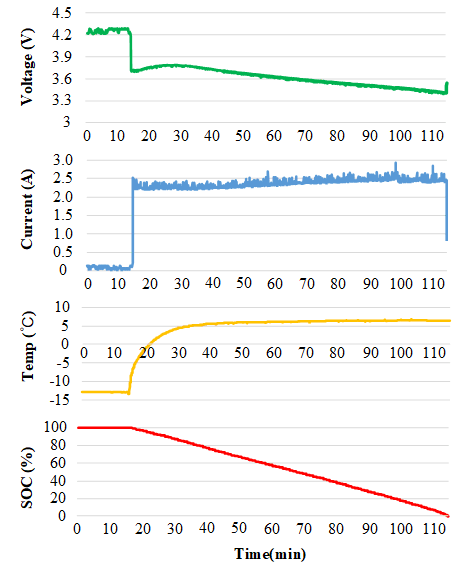

The undesired drop can be eliminated using following methods of this document, the optimization result is shown in Figure 1(b), which will surely improve the experience and prevent data loss due to abnormal shutdown.

| (a) 40% SOC Jump (before optimization) |

| (b) No SOC Jump (after optimization) |