ZHCS904I May 2012 – March 2017 TRF7964A

PRODUCTION DATA.

- 1器件概述

- 2修订历史记录

- 3Device Characteristics

- 4Terminal Configuration and Functions

- 5Specifications

-

6Detailed Description

- 6.1 Overview

- 6.2 System Block Diagram

- 6.3 Power Supplies

- 6.4 Receiver - Analog Section

- 6.5 Receiver - Digital Section

- 6.6 Oscillator Section

- 6.7 Transmitter - Analog Section

- 6.8 Transmitter - Digital Section

- 6.9 Transmitter - External Power Amplifier and Subcarrier Detector

- 6.10 TRF7964A IC Communication Interface

- 6.11 TRF7964A Initialization

- 6.12 Special Direct Mode for Improved MIFARE Compatibility

- 6.13

Direct Commands from MCU to Reader

- 6.13.1

Command Codes

- 6.13.1.1 Idle (0x00)

- 6.13.1.2 Software Initialization (0x03)

- 6.13.1.3 Reset FIFO (0x0F)

- 6.13.1.4 Transmission With CRC (0x11)

- 6.13.1.5 Transmission Without CRC (0x10)

- 6.13.1.6 Delayed Transmission With CRC (0x13)

- 6.13.1.7 Delayed Transmission Without CRC (0x12)

- 6.13.1.8 Transmit Next Time Slot (0x14)

- 6.13.1.9 Block Receiver (0x16)

- 6.13.1.10 Enable Receiver (0x17)

- 6.13.1.11 Test Internal RF (RSSI at RX Input With TX ON) (0x18)

- 6.13.1.12 Test External RF (RSSI at RX Input with TX OFF) (0x19)

- 6.13.1

Command Codes

- 6.14

Register Description

- 6.14.1 Register Preset

- 6.14.2 Register Overview

- 6.14.3

Detailed Register Description

- 6.14.3.1 Main Configuration Registers

- 6.14.3.2

Control Registers - Sublevel Configuration Registers

- 6.14.3.2.1 ISO/IEC 14443 TX Options Register (0x02)

- 6.14.3.2.2 ISO/IEC 14443 High-Bit-Rate and Parity Options Register (0x03)

- 6.14.3.2.3 TX Timer High Byte Control Register (0x04)

- 6.14.3.2.4 TX Timer Low Byte Control Register (0x05)

- 6.14.3.2.5 TX Pulse Length Control Register (0x06)

- 6.14.3.2.6 RX No Response Wait Time Register (0x07)

- 6.14.3.2.7 RX Wait Time Register (0x08)

- 6.14.3.2.8 Modulator and SYS_CLK Control Register (0x09)

- 6.14.3.2.9 RX Special Setting Register (0x0A)

- 6.14.3.2.10 Regulator and I/O Control Register (0x0B)

- 6.14.3.3

Status Registers

- 6.14.3.3.1 IRQ Status Register (0x0C)

- 6.14.3.3.2 Interrupt Mask Register (0x0D) and Collision Position Register (0x0E)

- 6.14.3.3.3 RSSI Levels and Oscillator Status Register (0x0F)

- 6.14.3.3.4 Special Functions Register (0x10)

- 6.14.3.3.5 Special Functions Register (0x11)

- 6.14.3.3.6 Adjustable FIFO IRQ Levels Register (0x14)

- 6.14.3.4 Test Registers

- 6.14.3.5 FIFO Control Registers

- 7Applications, Implementation, and Layout

- 8器件和文档支持

- 9机械、封装和可订购信息

6 Detailed Description

6.1 Overview

6.1.1 RFID – Reader and Writer

The is a high-performance 13.56-MHz HF RFID transceiver IC composed of an integrated analog front end (AFE) and a built-in data framing engine for ISO/IEC 15693, ISO/IEC 14443 A and B, and FeliCa. This includes data rates up to 848 kbps for ISO/IEC 14443 with all framing and synchronization tasks on board (in default mode). This architecture lets the customer build a complete cost-effective yet high-performance multiprotocol 13.56-MHz RFID system together with a low-cost microcontroller.

Other standards and even custom protocols can be implemented by using either of the direct modes that the device offers. These direct modes (0 and 1) allow the user to fully control the analog front end (AFE) and also gain access to the raw subcarrier data or the unframed but already ISO formatted data and the associated (extracted) clock signal.

The receiver system has a dual input receiver architecture. The receivers also include various automatic and manual gain control options. The received input bandwidth can be selected to cover a broad range of input subcarrier signal options.

The received signal strength from transponders, ambient sources, or internal levels is available through the RSSI register. The receiver output is selectable among a digitized subcarrier signal and any of the integrated subcarrier decoders. The selected subcarrier decoder delivers the data bit stream and the data clock as outputs.

The TRF7964A also includes a receiver framing engine. This receiver framing engine performs the CRC or parity check, removes the EOF and SOF settings, and organizes the data in bytes for ISO/IEC 14443 A and B, ISO/IEC 15693, and FeliCa protocols. Framed data is then accessible to the microcontroller (MCU) through a 127-byte FIFO register.

Figure 6-1 Application Block Diagram

Figure 6-1 Application Block Diagram

A parallel or serial interface (SPI) can be used for the communication between the MCU and the TRF7964A reader. When the built-in hardware encoders and decoders are used, transmit and receive functions use a 127-byte FIFO register. For direct transmit or receive functions, the encoders and decoders can be bypassed so that the MCU can process the data in real time. The TRF7964A supports data communication voltage levels from 1.8 V to 5.5 V for the MCU I/O interface. The transmitter has selectable output-power levels of 100 mW (+20 dBm) or 200 mW (+23 dBm) equivalent into a 50-Ω load when using a 5-V supply.

The transmitter supports OOK and ASK modulation with selectable modulation depth. The TRF7964A also includes a data transmission engine that comprises low-level encoding for ISO/IEC 15693, ISO/IEC 14443 A and B, and FeliCa. Included with the transmit data coding is the automatic generation of Start Of Frame (SOF), End Of Frame (EOF), Cyclic Redundancy Check (CRC), and parity bits.

Several integrated voltage regulators ensure a proper power-supply noise rejection for the complete reader system. The built-in programmable auxiliary voltage regulator VDD_X (pin 32), is able to deliver up to 20 mA to supply a microcontroller and additional external circuits within the reader system.

6.2 System Block Diagram

Figure 6-2 shows a block diagram of the TRF7964A.

Figure 6-2 System Block Diagram

Figure 6-2 System Block Diagram

6.3 Power Supplies

The TRF7964A positive supply input VIN (pin 2) sources three internal regulators with output voltages VDD_RF, VDD_A and VDD_X. All regulators use external bypass capacitors for supply noise filtering and must be connected as indicated in reference schematics. These regulators provide a high power supply reject ratio (PSRR) as required for RFID reader systems. All regulators are supplied by VIN (pin 2).

The regulators are not independent and have common control bits in register 0x0B for output voltage setting. The regulators can be configured to operate in either automatic or manual mode (register 0x0B, bit 7). The automatic regulator setting mode ensures an optimal compromise between PSRR and the highest possible supply voltage for RF output (to ensure maximum RF power output). The manual mode allows the user to manually configure the regulator settings. For applications in which the TRF7964A may be subjected to external noise, manually reducing the regulator settings can improve RF performance.

6.3.1 Supply Arrangements

Regulator Supply Input: VIN

The positive supply at VIN (pin 2) has an input voltage range of 2.7 V to 5.5 V. VIN provides the supply input sources for three internal regulators with the output voltages VDD_RF, VDD_A, and VDD_X. External bypass capacitors for supply noise filtering must be used (per reference schematics).

NOTE

VIN must be the highest voltage supplied to the TRF7964A.

RF Power Amplifier Regulator: VDD_RF

The VDD_RF (pin 3) regulator is supplying the RF power amplifier. The voltage regulator can be set for either 5-V or 3-V operation. External bypass capacitors for supply noise filtering must be used (per reference schematics). When configured for 5-V manual-operation, the VDD_RF output voltage can be set from 4.3 V to 5 V in 100-mV steps. In 3-V manual-operation, the output can be programmed from 2.7 V to 3.4 V in 100-mV steps. The maximum output current capability for 5-V operation is 150 mA and for 3-V operation is 100 mA.

Analog Supply Regulator: VDD_A

Regulator VDD_A (pin 1) supplies the analog circuits of the device. The output voltage setting depends on the input voltage and can be set for 5-V and 3-V operation. When configured for 5-V manual-operation, the output voltage is fixed at 3.4 V. External bypass capacitors for supply noise filtering must be used (per reference schematics). When configured for 3-V manual-operation, the VDD_A output can be set from 2.7 V to 3.4 V in 100-mV steps (see Table 6-2).

NOTE

The configuration of VDD_A and VDD_X regulators are not independent from each other. The VDD_X output current should not exceed 20 mA.

Digital Supply Regulator: VDD_X

The digital supply regulator VDD_X (pin 32) provides the power for the internal digital building blocks and can also be used to supply external electronics within the reader system. When configured for 3-V operation, the output voltage can be set from 2.7 to 3.4 V in 100-mV steps. External bypass capacitors for supply noise filtering must be used (per reference schematics).

NOTE

The configuration of the VDD_A and VDD_X regulators are not independent from each other. The VDD_X output current should not exceed 20 mA.

By default, the regulators are set in automatic regulator setting mode. In this mode, the regulators are automatically set every time the system is activated by setting EN input High or each time the automatic regulator setting bit, B7 in register 0x0B is set to a 1. The action is started on the 0 to 1 transition. This means that, if the user wants to rerun the automatic setting from a state in which the automatic setting bit is already high, the automatic setting bit (B7 in register 0x0B) should be changed: 1-0-1.

By default, the regulator setting algorithm sets the regulator outputs to a "Delta Voltage" of 400 mV below VIN, but not higher than 5 V for VDD_RF and 3.4 V for VDD_A and VDD_A.

Power Amplifier Supply: VDD_PA

The power amplifier of the TRF7964A is supplied through VDD_PA (pin 4). The positive supply pin for the RF power amplifier is externally connected to the regulator output VDD_RF (pin 3).

I/O Level Shifter Supply: VDD_I/O

The TRF7964A has a separate supply input VDD_I/O (pin 16) for the built-in I/O level shifter. The supported input voltage ranges from 1.8 V to VIN, not exceeding 5.5 V. Pin 16 is used to supply the I/O interface pins (I/O_0 to I/O_7), IRQ, SYS_CLK, and DATA_CLK pins of the reader. In typical applications, VDD_I/O is directly connected to VDD_X, while VDD_X also supplies the MCU. This ensures that the I/O signal levels of the MCU match the logic levels of the TRF7964A.

Negative Supply Connections: VSS, VSS_TX, VSS_RX, VSS_A, VSS_PA

The negative supply connections VSS_X of each functional block are all externally connected to GND.

The substrate connection is VSS (pin 10), the analog negative supply is VSS_A (pin 15), the logic negative supply is VSS_D (pin 29), the RF output stage negative supply is VSS_PA (pin 6), and the negative supply for the RF receiver VSS_RX (pin 7).

6.3.2 Supply Regulator Settings

The input supply voltage mode of the reader needs to be selected. This is done in the Chip Status Control register (0x00). Bit 0 in register 0x00 selects between 5-V or 3-V input supply voltage. The default configuration is 5 V, which reflects an operating supply voltage range of 4.3 V to 5.5 V. If the supply voltage is below 4.3 V, the 3-V configuration should be used.

As VDD_RF is increased, the system can become more susceptible to noise coupling on the RX lines. For minimum noise coupling, TI recommends using the value of 0x00. For improved range, higher VDD_RF voltages may be set, but complete system testing is required to determine the value which provides optimal performance.

The various regulators can be configured to operate in automatic or manual mode. This is done in the Regulator and I/O Control register (0x0B), as shown in Table 6-1 and Table 6-2.

Table 6-1 Supply Regulator Setting: 5-V System

| REGISTER ADDRESS (hex) |

OPTION BITS SETTING IN REGULATOR CONTROL REGISTER (1) | COMMENTS | |||||||

|---|---|---|---|---|---|---|---|---|---|

| B7 | B6 | B5 | B4 | B3 | B2 | B1 | B0 | ||

| Automatic Mode (default) | |||||||||

| 0B | 1 | x | x | x | x | x | 0 | 0 | Automatic regulator setting 400-mV difference |

| Manual Mode | |||||||||

| 0B | 0 | x | x | x | x | 1 | 1 | 1 | VDD_RF = 5 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 1 | 1 | 0 | VDD_RF = 4.9 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 1 | 0 | 1 | VDD_RF = 4.8 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 1 | 0 | 0 | VDD_RF = 4.7 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 0 | 1 | 1 | VDD_RF = 4.6 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 0 | 1 | 0 | VDD_RF = 4.5 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 0 | 0 | 1 | VDD_RF = 4.4 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 0 | 0 | 0 | VDD_RF = 4.3 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

Table 6-2 Supply Regulator Setting: 3-V System

| REGISTER ADDRESS (hex) |

OPTION BITS SETTING IN REGULATOR CONTROL REGISTER (1) | COMMENTS | |||||||

|---|---|---|---|---|---|---|---|---|---|

| B7 | B6 | B5 | B4 | B3 | B2 | B1 | B0 | ||

| Automatic Mode (default) | |||||||||

| 0B | 1 | x | x | x | x | x | 0 | 0 | Automatic regulator setting 400-mV difference |

| Manual Mode | |||||||||

| 0B | 0 | x | x | x | x | 1 | 1 | 1 | VDD_RF = 3.4 V, VDD_A = 3.4 V, VDD_X = 3.4 V |

| 0B | 0 | x | x | x | x | 1 | 1 | 0 | VDD_RF = 3.3 V, VDD_A = 3.3 V, VDD_X = 3.3 V |

| 0B | 0 | x | x | x | x | 1 | 0 | 1 | VDD_RF = 3.2 V, VDD_A = 3.2 V, VDD_X = 3.2 V |

| 0B | 0 | x | x | x | x | 1 | 0 | 0 | VDD_RF = 3.1 V, VDD_A = 3.1 V, VDD_X = 3.1 V |

| 0B | 0 | x | x | x | x | 0 | 1 | 1 | VDD_RF = 3.0 V, VDD_A = 3.0 V, VDD_X = 3.0 V |

| 0B | 0 | x | x | x | x | 0 | 1 | 0 | VDD_RF = 2.9 V, VDD_A = 2.9 V, VDD_X = 2.9 V |

| 0B | 0 | x | x | x | x | 0 | 0 | 1 | VDD_RF = 2.8 V, VDD_A = 2.8 V, VDD_X = 2.8 V |

| 0B | 0 | x | x | x | x | 0 | 0 | 0 | VDD_RF = 2.7 V, VDD_A = 2.7 V, VDD_X = 2.7 V |

The regulator configuration function adjusts the regulator outputs by default to 400 mV below VIN level, but not higher than 5 V for VDD_RF, 3.4 V for VDD_A and VDD_X. This ensures the highest possible supply voltage for the RF output stage while maintaining an adequate PSRR (power supply rejection ratio).

6.3.3 Power Modes

The chip has several power states, which are controlled by two input pins (EN and EN2) and several bits in the chip status control register (0x00) (see Table 6-3 and Table 6-4).

Table 6-3 3.3-V Operation Power Modes(1)

| MODE | EN2 | EN | CHIP STATUS CONTROL REGISTER (0x00) | REGULATOR CONTROL REGISTER (0x0B) | TRANSMITTER | RECEIVER | SYS_CLK (13.56 MHz) | SYS_CLK (60 kHz) | VDD_X | TYPICAL CURRENT (mA) | TYPICAL POWER OUT (dBm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Power down | 0 | 0 | XX | XX | OFF | OFF | OFF | OFF | OFF | <0.001 | - |

| Sleep mode | 1 | 0 | XX | XX | OFF | OFF | OFF | ON | ON | 0.120 | - |

| Standby mode at +3.3 VDC | X | 1 | 80 | 00 | OFF | OFF | ON | X | ON | 2 | - |

| Mode 1 at +3.3 VDC | X | 1 | 00 | 00 | OFF | OFF | ON | X | ON | 3 | - |

| Mode 2 at +3.3 VDC | X | 1 | 02 | 00 | OFF | ON | ON | X | ON | 9 | - |

| Mode 3 (half power) at +3.3 VDC | X | 1 | 30 | 07 | ON | ON | ON | X | ON | 53 | 14.5 |

| Mode 4 (full power) at +3.3 VDC | X | 1 | 20 | 07 | ON | ON | ON | X | ON | 67 | 17 |

Table 6-4 5-V Operation Power Modes(1)

| MODE | EN2 | EN | CHIP STATUS CONTROL REGISTER (0x00) | REGULATOR CONTROL REGISTER (0x0B) | TRANSMITTER | RECEIVER | SYS_CLK (13.56 MHz) | SYS_CLK (60 kHz) | VDD_X | TYPICAL CURRENT (mA) | TYPICAL POWER OUT (dBm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Power down | 0 | 0 | XX | XX | OFF | OFF | OFF | OFF | OFF | <0.001 | - |

| Sleep mode | 1 | 0 | XX | XX | OFF | OFF | OFF | ON | ON | 0.120 | - |

| Standby mode at +5 VDC | X | 1 | 81 | 07 | OFF | OFF | ON | X | ON | 3 | - |

| Mode 1 at +5 VDC | X | 1 | 01 | 07 | OFF | OFF | ON | X | ON | 5 | - |

| Mode 2 at +5 VDC | X | 1 | 03 | 07 | OFF | ON | ON | X | ON | 10.5 | - |

| Mode 3 (half power) at +5 VDC | X | 1 | 31 | 07 | ON | ON | ON | X | ON | 70 | 20 |

| Mode 4 (full power) at +5 VDC | X | 1 | 21 | 07 | ON | ON | ON | X | ON | 130 | 23 |

Table 6-3 and Table 6-4 show the configuration for the different power modes when using a 3.3-V or 5-V system supply, respectively. The main reader enable signal is pin EN. When EN is set high, all of the reader regulators are enabled, the 13.56-MHz oscillator is running and the SYS_CLK (output clock for external microcontroller) is also available.

The input pin EN2 has two functions:

- A direct connection from EN2 to VIN to ensure the availability of the regulated supply VDD_X and an auxiliary clock signal (60 kHz, SYS_CLK) for an external MCU. This mode (EN = 0, EN2 = 1) is intended for systems in which the MCU is also being supplied by the reader supply regulator (VDD_X) and the MCU clock is supplied by the SYS_CLK output of the reader. This allows the MCU supply and clock to be available during sleep mode.

- EN2 enables the start-up of the reader system from complete power down (EN = 0, EN2 = 0). In this case the EN input is being controlled by the MCU (or other system device) that is without supply voltage during complete power down (thus unable to control the EN input). A rising edge applied to the EN2 input (which has an approximately 1-V threshold level) starts the reader supply system and 13.56-MHz oscillator (identical to condition EN = 1).

When user MCU is controlling EN and EN2, a delay of 1 ms between EN and EN2 must be used. If the MCU controls only EN, TI recommends connecting EN2 to either VIN or GND, depending on the application MCU requirements for VDD_X and SYS_CLK.

This start-up mode lasts until all of the regulators have settled and the 13.56-MHz oscillator has stabilized. If the EN input is set high (EN = 1) by the MCU (or other system device), the reader stays active. If the EN input is not set high (EN = 0) within 100 µs after the SYS_CLK output is switched from auxiliary clock (60 kHz) to high-frequency clock (derived from the crystal oscillator), the reader system returns to complete Power-Down Mode 1. This option can be used to wake-up the reader system from complete Power Down (PD Mode 1) by using a pushbutton switch or by sending a single pulse.

After the reader EN line is high, the other power modes are selected by control bits within the chip status control register (0x00). The power mode options and states are listed in Table 6-3.

When EN is set high (or on rising edge of EN2 and then confirmed by EN = 1) the supply regulators are activated and the 13.56-MHz oscillator is started. When the supplies are settled and the oscillator frequency is stable, the SYS_CLK output is switched from the auxiliary frequency of 60 kHz to the 13.56-MHz frequency derived from the crystal oscillator. At this point, the reader is ready to communicate and perform the required tasks. When this occurs, osc_ok (B6) of the RSSI Level and Oscillator Status register is set. The MCU can then program the Chip Status Control register 0x00 and select the operation mode by programming the additional registers.

- Standby Mode (bit 7 = 1 of register 0x00), the reader is capable of recovering to full operation in 100 µs.

- Mode 1 (active mode with RF output disabled, bit 5 = 0 and bit 1 = 0 of register 0x00) is a low power mode which allows the reader to recover to full operation within 25 µs.

- Mode 2 (active mode with only the RF receiver active, bit 1 = 1 of register 0x00) can be used to measure the external RF field (as described in RSSI measurements paragraph) if reader-to-reader anticollision is implemented.

- Modes 3 and 4 (active modes with the entire RF section active, bit 5 = 1 of register 0x00) are the normal modes used for normal transmit and receive operations.

6.4 Receiver – Analog Section

6.4.1 Main and Auxiliary Receivers

The TRF7964A has two receiver inputs: RX_IN1 (pin 8) and RX_IN2 (pin 9). Each of the input is connected to an external capacitive voltage divider to ensure that the modulated signal from the tag is available on at least one of the two inputs. This architecture eliminates any possible communication holes that may occur from the tag to the reader.

The two RX inputs (RX_IN1 and RX_IN2) are multiplexed into two receivers - the main receiver and the auxiliary receiver. Only the main receiver is used for reception, the auxiliary receiver is used for signal quality monitoring. Receiver input multiplexing is controlled by bit B3 in the Chip Status Control register (address 0x00).

After start-up, RX_IN1 is multiplexed to the main receiver which is composed of an RF envelope detection, first gain and band-pass filtering stage, second gain and filtering stage with AGC. Only the main receiver is connected to the digitizing stage which output is connected to the digital processing block. The main receiver also has an RSSI measuring stage, which measures the strength of the demodulated signal (subcarrier signal).

The primary function of the auxiliary receiver is to monitor the RX signal quality by measuring the RSSI of the demodulated subcarrier signal (internal RSSI). After start-up, RX_IN2 is multiplexed to the auxiliary receiver. The auxiliary receiver has an RF envelope detection stage, first gain and filtering with AGC stage and finally the auxiliary RSSI block.

The default MUX setting is RX_IN1 connected to the main receiver and RX_IN2 connected to the auxiliary receiver. To determine the signal quality, the response from the tag is detected by the "main" (pin RX_IN1) and "auxiliary" (pin RX_IN2) RSSI. Both values measured and stored in the RSSI Levels and Oscillator Status register (address 0x0F). The MCU can read the RSSI values from the TRF7964A RSSI register and make the decision if swapping the input- signals is preferable or not. Setting B3 in Chip Status Control register (address 0x00) to 1 connects RX_IN1 (pin 8) to the auxiliary received and RX_IN2 (pin 9) to the main receiver.

The main and auxiliary receiver input stages are RF envelope detectors. The RF amplitude at RX_IN1 and RX_IN2 should be approximately 3 VPP for a VINsupply level greater than 3.3 V. If the VIN level is lower, the RF input peak-to-peak voltage level should not exceed the VINlevel.

6.4.2 Receiver Gain and Filter Stages

The first gain and filtering stage has a nominal gain of 15 dB with an adjustable band-pass filter. The band-pass filter has programmable 3-dB corner frequencies between 110 kHz to 450 kHz for the high-pass filter and 570 kHz to 1500 kHz for the low-pass filter. After the band-pass filter, there is another gain-and-filtering stage with a nominal gain of 8 dB and with frequency characteristics identical to the first band-pass stage.

The internal filters are configured automatically depending on the selected ISO communication standard in the ISO Control register (address 0x01). If required, additional fine tuning can be done by writing directly to the RX Special Setting registers (address 0x0A).

Table 6-5 shows the various settings for the receiver analog section. Setting B4, B5, B6, and B7 to 0 results in a band-pass characteristic of 240 kHz to 1.4 MHz, which is appropriate for ISO/IEC 14443 B 106 kbps, ISO/IEC 14443 A and B data rates of 212 kbps and 424 kbps, and FeliCa 424 kbps.

Table 6-5 RX Special Setting Register (0x0A)

| Function: Sets the gains and filters directly | |||

| Default: 0x40 at POR = H or EN = L, and at each write to the ISO Control register (0x01). When bits B7, B6, B5 and B4 are all zero, the filters are set for ISO/IEC 14443 B (240 kHz to 1.4 MHz). | |||

| Bit | Name | Function | Description |

| B7 | C212 | Band-pass 110 kHz to 570 kHz | Appropriate for 212-kHz subcarrier system (FeliCa) |

| B6 | C424 | Band-pass 200 kHz to 900 kHz | Appropriate for 424-kHz subcarrier used in ISO/IEC 15693 |

| B5 | M848 | Band-pass 450 kHz to 1.5 MHz | Appropriate for Manchester-coded 848-kHz subcarrier used in ISO/IEC 14443 A and B |

| B4 | hbt | Band-pass 100 kHz to 1.5 MHz Gain reduced for 18 dB |

Appropriate for highest bit rate (848 kbps) used in high-bit-rate ISO/IEC 14443 |

| B3 | gd1 | 00 = Gain reduction 0 dB 01 = Gain reduction for 5 dB 10 = Gain reduction for 10 dB 11 = Gain reduction for 15 dB |

Sets the RX gain reduction and reduces sensitivity |

| B2 | gd2 | ||

| B1 | Reserved | ||

| B0 | Reserved | ||

6.5 Receiver – Digital Section

The output of the TRF7964A analog receiver block is a digitized subcarrier signal and is the input to the digital receiver block, which consists of two sections that partly overlap. The digitized subcarrier signal is a digital representation of the modulation signal on the RF envelope. The two sections of the digital receiver block are the protocol bit decoder section and the framing logic section.

The protocol bit decoder section converts the subcarrier coded signal into a serial bit stream and a data clock. The decoder logic is designed for maximum error tolerance. This tolerance lets the decoder section successfully decode even partly corrupted subcarrier signals that would otherwise be lost due to noise or interference.

The framing logic section formats the serial bit stream data from the protocol bit decoder stage into data bytes. During the formatting process, special signals such as the start of frame (SOF), end of frame (EOF), start of communication, and end of communication are automatically removed. The parity bits and CRC bytes are also checked and removed. The end result is "clean or raw" data that is sent to the 127-byte FIFO register where it can be read by the external microcontroller system. Providing the data this way, in conjunction with the timing register settings of the TRF7964A, means that the firmware developer does not need to know the finer details of the ISO protocols to create a very robust application, especially in low-cost platforms in which code space is at a premium and high performance is still required.

The start of the receive operation (successfully received SOF) sets the IRQ flags in the IRQ Status register (0x0C). The end of the receive operation is signaled to the external system MCU by setting pin 13 (IRQ) to high. When data is received in the FIFO, an interrupt is sent to the MCU to signal that there is data to be read from the FIFO. The FIFO Status register (0x1C) should be used to provide the number of bytes that should be clocked out during the actual FIFO read. Additionally, an interrupt is sent to the MCU when the received data occupies 75% of the FIFO capacity to signal that the data should be removed from the FIFO. By default, that interrupt is triggered once the received data packet is longer than 124 bytes. This setting can be modified in the Adjustable FIFO IRQ Levels register (0x14).

Any error in the data format, parity, or CRC is detected and notified to the external system by setting pin 13 (IRQ) to high. The source condition of the interrupt is available in the IRQ Status register (0x0C). Section 6.14.3.3.1 describes the bit coding description of this register.

The framing section also supports bit-collision detection as specified in ISO/IEC 14443 A and ISO/IEC 15693. When a bit collision is detected, an interrupt request is sent and a flag is set in the IRQ Status register (0x0C). For ISO/IEC 14443 A specifically, the position of the bit collision is written in two registers: partly in the Collision Position register (0x0E) and partly in the Collision Position and Interrupt Mask register (0x0D) (bits B6 and B7).

This collision position is presented as sequential bit number, where the count starts immediately after the start bit. This means a collision in the first bit of a UID would give the value 00 0001 0000 in these registers when their contents are combined after being read (the count starts with 0 and the first 16 bits are the command code and the number of valid bits [NVB] byte).

The receive section also contains two timers.

The RX wait time timer is controlled by the value in the RX Wait Time register (0x08). This timer defines the time interval after the end of the transmit operation during which the receive decoders are not active (held in reset state). This prevents false detections resulting from transients following the transmit operation. The value of the RX Wait Time register (0x08) defines the time in increments of 9.44 µs. This register is preset at every write to the ISO Control register (0x01) according to the minimum tag response time defined by each standard.

The RX no response timer is controlled by the RX No Response Wait Time register (0x07). This timer measures the time from the start of the slot in the anticollision sequence until the start of tag response. If there is no tag response in the defined time, an interrupt request is sent and a flag is set in the IRQ Status register (0x0C). This enables the external controller to be relieved of the task of detecting empty slots. The wait time is stored in the register in increments of 37.76 µs. This register is also preset automatically for every new protocol selection.

The main register controlling the digital part of the receiver is the ISO Control register (0x01). By writing to this register, the user selects the protocol to be used. With each new write in this register, all related registers are preset to their defaults for the protocol, so no further adjustments in other registers are needed for proper operation. Table 6-6 describes the bit fields of the ISO Control register (0x01).

NOTE

If changes to other registers are needed to fine-tune the system, those changes must be made after setting the ISO Control register (0x01).

Table 6-6 Coding of the ISO Control Register

| BIT | SIGNAL NAME | FUNCTION | COMMENTS |

|---|---|---|---|

| B7 | rx_crc_n | Receiving without CRC |

1 = No RX CRC 0 = RX CRC |

| B6 | dir_mode | Direct mode type |

0 = Output is subcarrier data 1 = Output is bit stream and clock from decoder selected by ISO bits |

| B5 | rfid | RFID mode |

0 = RFID reader mode 1 = Reserved (should be set to 0) |

| B4 | iso_4 | RFID |

See Table 6-7 for B0:B4 settings based on ISO protocol used by application. |

| B3 | iso_3 | RFID |

See Table 6-7 for B0:B4 settings based on ISO protocol used by application. |

| B2 | iso_2 | RFID |

See Table 6-7 for B0:B4 settings based on ISO protocol used by application. |

| B1 | iso_1 | RFID |

See Table 6-7 for B0:B4 settings based on ISO protocol used by application. |

| B0 | iso_0 | RFID |

See Table 6-7 for B0:B4 settings based on ISO protocol used by application. |

Table 6-7 Coding of the ISO Control Register For RFID Mode (B5 = 0)

| Iso_4 | Iso_3 | Iso_2 | Iso_1 | Iso_0 | PROTOCOL | REMARKS |

|---|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | ISO/IEC 15693 low bit rate, one subcarrier, 1 out of 4 | |

| 0 | 0 | 0 | 0 | 1 | ISO/IEC 15693 low bit rate, one subcarrier, 1 out of 256 | |

| 0 | 0 | 0 | 1 | 0 | ISO/IEC 15693 high bit rate, one subcarrier, 1 out of 4 | Default for RFID IC |

| 0 | 0 | 0 | 1 | 1 | ISO/IEC 15693 high bit rate, one subcarrier, 1 out of 256 | |

| 0 | 0 | 1 | 0 | 0 | ISO/IEC 15693 low bit rate, double subcarrier, 1 out of 4 | |

| 0 | 0 | 1 | 0 | 1 | ISO/IEC 15693 low bit rate, double subcarrier, 1 out of 256 | |

| 0 | 0 | 1 | 1 | 0 | ISO/IEC 15693 high bit rate, double subcarrier, 1 out of 4 | |

| 0 | 0 | 1 | 1 | 1 | ISO/IEC 15693 high bit rate, double subcarrier, 1 out of 256 | |

| 0 | 1 | 0 | 0 | 0 | ISO/IEC 14443 A, bit rate 106 kbps | |

| 0 | 1 | 0 | 0 | 1 | ISO/IEC 14443 A high bit rate 212 kbps | RX bit rate when TX rate different from RX rate (see register 0x03) |

| 0 | 1 | 0 | 1 | 0 | ISO/IEC 14443 A high bit rate 424 kbps | |

| 0 | 1 | 0 | 1 | 1 | ISO/IEC 14443 A high bit rate 848 kbps | |

| 0 | 1 | 1 | 0 | 0 | ISO/IEC 14443 B, bit rate 106 kbps | |

| 0 | 1 | 1 | 0 | 1 | ISO/IEC 14443 B high bit rate 212 kbps | RX bit rate when TX rate different from RX rate (see register 0x03) |

| 0 | 1 | 1 | 1 | 0 | ISO/IEC 14443 B high bit rate 424 kbps | |

| 0 | 1 | 1 | 1 | 1 | ISO/IEC 14443 B high bit rate 848 kbps | |

| 1 | 0 | 0 | 1 | 1 | Reserved | |

| 1 | 0 | 1 | 0 | 0 | Reserved | |

| 1 | 1 | 0 | 1 | 0 | FeliCa 212 kbps | |

| 1 | 1 | 0 | 1 | 1 | FeliCa 424 kbps |

6.5.1 Received Signal Strength Indicator (RSSI)

The TRF7964A incorporates in total three independent RSSI building blocks: Internal Main RSSI, Internal Auxiliary RSSI, and External RSSI. The internal RSSI blocks measure the amplitude of the subcarrier signal, and the external RSSI block measures the amplitude of the RF carrier signal at the receiver input.

6.5.1.1 Internal RSSI – Main and Auxiliary Receivers

Each receiver path has its own RSSI block to measure the envelope of the demodulated RF signal (subcarrier). Internal Main RSSI and Internal Auxiliary RSSI are identical however connected to different RF input pins. The Internal RSSI is intended for diagnostic purposes to set the correct RX path conditions.

The internal RSSI values can be used to adjust the RX gain settings or determine which RX path (main or auxiliary) provides the greater amplitude and, hence, to determine if the MUX may need to be reprogrammed to swap the RX input signal. The measuring system latches the peak value, so the RSSI level can be read after the end of each receive packet. The RSSI register values are reset with every transmission (TX) by the reader. This ensures an updated RSSI measurement for each new tag response.

The Internal RSSI has 7 steps (3 bit) with a typical increment of approximately 4 dB. The operating range is between 600 mVPP and 4.2 VPP with a typical step size of approximately 600 mV. Both Internal Main and Internal Auxiliary RSSI values are stored in the RSSI Levels and Oscillator Status register (0x0F). The nominal relationship between the input RF peak level and the RSSI value is shown in Figure 6-5.

Figure 6-5 Digital Internal RSSI (Main and Auxiliary) Value vs RF Input Level in VPP (V)

Figure 6-5 Digital Internal RSSI (Main and Auxiliary) Value vs RF Input Level in VPP (V)

This RSSI measurement is done during the communication to the Tag; this means the TX must be on. Bit 1 in the Chip Status Control register (0x00) defines if Internal RSSI or the External RSSI value is stored in the RSSI Levels and Oscillator Status register (0x0F). Direct command 0x18 is used to trigger an Internal RSSI measurement.

6.5.1.2 External RSSI

The external RSSI is mainly used to check for any external 13.56-MHz signals at the receiver RX_IN1 input. The external RSSI measurement should be used before turning on the transmitter to prevent RF field collisions. This is especially important for active mode, when both devices emit their own RF field. The level of the RF signal received at the antenna is measured and stored in the RSSI Levels and Oscillator Status register (0x0F). Figure 6-6 shows the relationship between the voltage at the RX_IN1 input and the 3-bit code.

Figure 6-6 Digital External RSSI Value vs RF Input Level in VPP (mV)

Figure 6-6 Digital External RSSI Value vs RF Input Level in VPP (mV)

The relation between the 3-bit code and the external RF field strength (A/m) sensed by the antenna must be determined by calculation or by experiments for each antenna design. The antenna Q-factor and connection to the RF input influence the result. Direct command 0x19 is used to trigger an external RSSI measurement.

For clarity, to check the internal or external RSSI value independent of any other operation, the user must:

- Set transmitter to desired state (on or off) using Bit 5 of Chip Status Control register (0x00) and enable receiver using Bit 1.

- Check internal or external RSSI using direct commands 0x18 or 0x19, respectively. This action places the RSSI value in the RSSI register.

- Delay at least 50 µs.

- Read the RSSI register using direct command 0x0F; values range from 0x40 to 0x7F.

- Repeat steps 1 to 4 as needed. The register is reset when it is read.

6.6 Oscillator Section

The 13.56-MHz or 27.12-MHz crystal (or oscillator) is controlled by the Chip Status Control register (0x00) and the EN and EN2 terminals. The oscillator generates the RF frequency for the RF output stage as well as the clock source for the digital section. The buffered clock signal is available at pin 27 (SYS_CLK) for any other external circuits. B4 and B5 inside the Modulation and SYS_CLK register (0x09) can be used to divide the external SYS_CLK signal at pin 27 by 1, 2, or 4.

Typical start-up time from complete power down is in the range of 3.5 ms.

During Power Down Mode 2 (EN = 0, EN2 = 1) the frequency of SYS_CLK is switched to 60 kHz (typical).

The crystal needs to be connected between pin 30 and pin 31. The external shunt capacitors values for C1 and C2 must be calculated based on the specified load capacitance of the crystal being used. The external shunt capacitors are calculated as two identical capacitors in series plus the stray capacitance of the TRF7964A and parasitic PCB capacitance in parallel to the crystal.

The parasitic capacitance (CS, stray and parasitic PCB capacitance) can be estimated at 4 to 5 pF (typical).

As an example, using a crystal with a required load capacitance (CL) of 18 pF, the calculation is shown in Equation 1.

A 27-pF capacitor must be placed on pins 30 and 31 to ensure proper crystal oscillator operation.

Figure 6-7 Crystal Block Diagram

Figure 6-7 Crystal Block Diagram

Any crystal used with TRF7964A should meet the minimum characteristics in Table 6-8.

Table 6-8 Minimum Crystal Recommendations

| PARAMETER | SPECIFICATION |

|---|---|

| Frequency | 13.56 MHz or 27.12 MHz |

| Mode of operation | Fundamental |

| Type of resonance | Parallel |

| Frequency tolerance | ±20 ppm |

| Aging | < 5 ppm/year |

| Operation temperature range | –40°C to 85°C |

As an alternative, an external clock oscillator source can be connected to pin 31 to provide the system clock; pin 30 can be left open.

6.7 Transmitter – Analog Section

The 13.56-MHz oscillator generates the RF signal for the PA stage. The power amplifier consists of a driver with selectable output resistance of nominal 4 Ω or 8 Ω. The transmit power level is set by bit B4 in the Chip Status Control register (0x00). The transmit power levels are selectable between 100 mW (half power) or 200 mW (full power) when configured for 5-V automatic operation. The transmit power levels are selectable between 33 mW (half power) or 70 mW (full power) when configured for 3-V automatic operation.

The ASK modulation depth is controlled by bits B0, B1, and B2 in the Modulator and SYS_CLK Control register (0x09). The ASK modulation depth range can be adjusted between 7% to 30% or 100% (OOK).

External control of the transmit modulation depth is possible by setting the ISO Control register (0x01) to direct mode. While operating the TRF7964A in direct mode, the transmit modulation is made possible by selecting the modulation type ASK or OOK at pin 12. External control of the modulation type is made possible only if enabled by setting B6 in the Modulator and SYS_CLK Control register (0x09) to 1.

In normal operation mode, the length of the modulation pulse is defined by the protocol selected in the ISO Control register (0x01). With a high-Q antenna, the modulation pulse is typically prolonged, and the tag detects a longer pulse than intended. For such cases, the modulation pulse length needs to be corrected by using the TX Pulse Length Control register (0x06).

If the register contains all zeros, then the pulse length is governed by the protocol selection. If the register contains a value other than 0x00, the pulse length is equal to the value of the register multiplied by 73.7 ns; therefore, the pulse length can be adjusted between 73.7 ns and 18.8 µs in 73.7-ns increments.

6.8 Transmitter – Digital Section

The digital part of the transmitter is a mirror of the receiver. The settings controlled the ISO Control register (0x01) are applied to the transmitter just like the receiver. In the TRF7964A default mode the TRF7964A automatically adds these special signals: start of communication, end of communication, SOF, EOF, parity bits, and CRC bytes.

The data is then coded to modulation pulse levels and sent to the RF output stage modulation control unit. Similar to working with the receiver, this means that the external system MCU must only load the FIFO with data, and all the microcoding is done automatically, again saving the firmware developer code space and time. Additionally, all of the registers used for transmit parameter control are automatically preset to optimum values when a new selection is entered into the ISO Control register (0x01).

NOTE

The FIFO must be reset before starting any transmission with direct command 0x0F.

There are two ways to start the transmit operation:

- Send the transmit command and the number of bytes to be transmitted first, and then start to send the data to the FIFO. The transmission starts when first data byte is written into the FIFO.

- Load the number of bytes to be sent into registers 0x1D and 0x1E and load the data to be sent into the FIFO (address 0x1F), followed by sending a transmit command (see Direct Commands section). The transmission then starts when the transmit command is received.

NOTE

If the data length is longer than the FIFO, the TRF7964A notifies the external system MCU when most of the data from the FIFO has been transmitted by sending an interrupt request with a flag in the IRQ register to indicate a FIFO low or high status. The external system should respond by loading the next data packet into the FIFO.

At the end of a transmit operation, the external system MCU is notified by interrupt request (IRQ) with a flag in IRQ register (0x0C) indicating TX is complete (example value = 0x80).

The TX Length registers also support incomplete byte transmission. The high two nibbles in register 0x1D and the nibble composed of bits B4 through B7 in register 0x1E store the number of complete bytes to be transmitted. Bit B0 in register 0x1E is a flag indicating that there are also additional bits to be transmitted that do not form a complete byte. The number of bits is stored in bits B1 through B3 of the same register (0x1E).

Some protocols have options, and there are two sublevel configuration registers to select the TX protocol options.

- ISO/IEC 14443 B TX Options register (0x02). This register controls the SOF and EOF selection and EGT selection for the ISO/IEC 14443 B protocol.

- ISO/IEC 14443 A High Bit Rate Options and Parity register (0x03). This register enables the use of different bit rates for RX and TX operations in the ISO/IEC 14443 high bit rate protocol and also selects the parity method in the ISO/IEC 14443 A high bit rate protocol.

The digital section also has a timer. The timer can be used to start the transmit operation at a specified time in accordance with a selected event.

6.9 Transmitter – External Power Amplifier and Subcarrier Detector

The TRF7964A can be used in conjunction with an external TX power amplifier or external subcarrier detector for the receiver path. In this case, certain registers must be programmed as shown here:

- Bit B6 of the Regulator and I/O Control register (0x0B) must be set to 1. This setting has two functions: first, to provide a modulated signal for the transmitter if needed, and second, to configure the TRF7964A receiver inputs for an external demodulated subcarrier input.

- Bit B3 of the Modulation and SYS_CLK Control register (0x09) must be set to 1 (see Section 6.14.3.2.8). This function configures the ASK/OOK pin for either a digital or analog output (B3 = 0 enables a digital output, B3 = 1 enables an analog output). The design of an external power amplifier requires detailed RF knowledge. There are also readily designed and certified high-power HF reader modules on the market.

6.10 TRF7964A IC Communication Interface

6.10.1 General Introduction

The communication interface to the reader can be configured in two ways: with a eight line parallel interface (D0:D7) plus DATA_CLK, or with a 4-wire Serial Peripheral Interface (SPI). The SPI interface uses traditional Master Out/Slave In (MOSI), Master In/Slave Out (MISO), Slave Select, and DATA_CLK lines.

These communication modes are mutually exclusive; that is, only one mode can be used at a time in the application.

When the SPI interface is selected, the unused I/O_2, I/O_1, and I/O_0 pins must be hard-wired as shown in Table 6-9. At power up, the TRF7964A samples the status of these three pins and then enters one of the possible SPI modes.

The TRF7964A always behaves as the slave device, and the microcontroller (MCU) behaves as the master device. The MCU initiates all communications with the TRF7964A, and the TRF7964A makes use of the Interrupt Request (IRQ) pin in both parallel and SPI modes to prompt the MCU for servicing attention.

Table 6-9 Pin Assignment in Parallel and Serial Interface Connection or Direct Mode

| PIN | PARALLEL | PARALLEL (DIRECT MODE) | SPI WITH SS | SPI WITHOUT SS(5) |

|---|---|---|---|---|

| DATA_ CLK | DATA_CLK | DATA_CLK | DATA_CLK from master | DATA_CLK from master |

| I/O_7 | A/D[7] | Not used | MOSI(1) = data in (reader in) | MOSI(1) = data in (reader in) |

| I/O_6 | A/D[6] | Direct mode, data out (subcarrier or bit stream) | MISO(2) = data out (MCU out) | MISO(2) = data out (MCU out) |

| I/O_5(3) | A/D[5] | Direct mode, strobe – bit clock out | See (3). | See (3). |

| I/O_4 | A/D[4] | Not used | SS – slave select(4) | Not used |

| I/O_3 | A/D[3] | Not used | Not used | Not used |

| I/O_2 | A/D[2] | Not used | At VDD | At VDD |

| I/O_1 | A/D[1] | Not used | At VDD | At VSS |

| I/O_0 | A/D[0] | Not used | At VSS | At VSS |

| IRQ | IRQ interrupt | IRQ interrupt | IRQ interrupt | IRQ interrupt |

Communication is initialized by a start condition, which is expected to be followed by an Address/Command word (Adr/Cmd). The Adr/Cmd word is 8 bits long, and Table 6-10 shows its format.

Table 6-10 Address and Command Word Bit Distribution

| BIT | DESCRIPTION | BIT FUNCTION | ADDRESS | COMMAND |

|---|---|---|---|---|

| B7 | Command control bit | 0 = Address 1 = Command |

0 | 1 |

| B6 | Read/Write | 0 = Write 1 = Read |

R/W | 0 |

| B5 | Continuous address mode | 1 = Continuous mode | R/W | 0 |

| B4 | Address/Command bit 4 | Adr 4 | Cmd 4 | |

| B3 | Address/Command bit 3 | Adr 3 | Cmd 3 | |

| B2 | Address/Command bit 2 | Adr 2 | Cmd 2 | |

| B1 | Address/Command bit 1 | Adr 1 | Cmd 1 | |

| B0 | Address/Command bit 0 | Adr 0 | Cmd 0 |

The MSB (bit 7) determines if the word is to be used as a command or as an address. The last two columns of Table 6-10 show the function of the separate bits if either address or command is written. Data is expected once the address word is sent. In continuous-address mode (Cont. mode = 1), the first data that follows the address is written (or read) to (from) the given address. For each additional data, the address is incremented by one. Continuous mode can be used to write to a block of control registers in a single stream without changing the address; for example, setup of the predefined standard control registers from the MCU nonvolatile memory to the reader. In noncontinuous address mode (simple addressed mode), only one data word is expected after the address.

Address Mode is used to write or read the configuration registers or the FIFO. When writing more than 12 bytes to the FIFO, the Continuous Address Mode should be set to 1.

Command Mode is used to enter a command resulting in reader action (for example, initialize transmission, enable reader, and turn reader on or off).

The following sections give examples of the expected communications between an MCU and the TRF7964A.

6.10.1.1 Continuous Address Mode

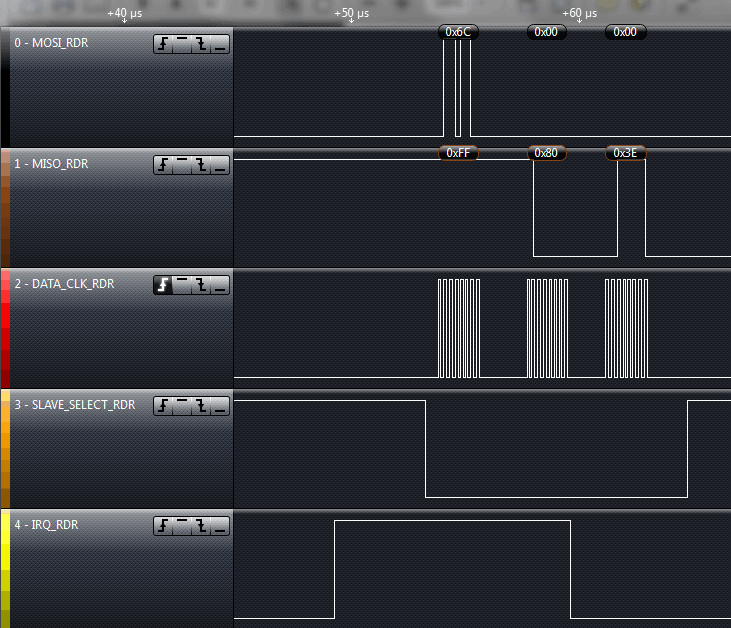

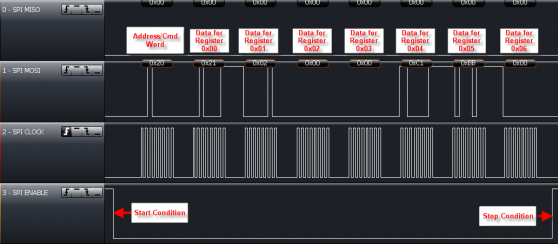

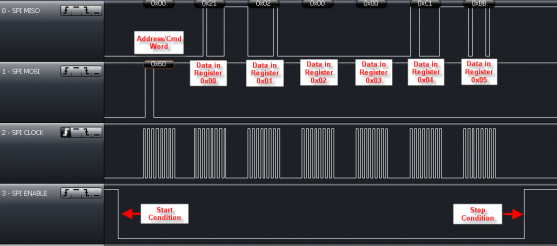

Figure 6-8 summarizes the continuous address mode communication. Figure 6-8 and Figure 6-9 show the signals between the MCU and the TRF7964A.

Table 6-11 Continuous Address Mode

| Start | Adr x | Data(x) | Data(x+1) | Data(x+2) | Data(x+3) | Data(x+4) | ... | Data(x+n) | StopCont |

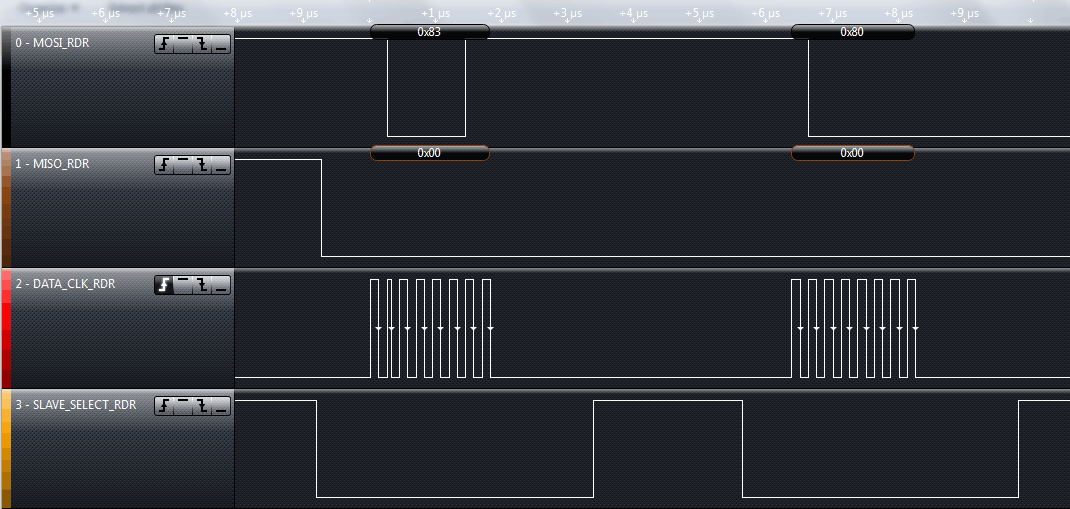

Figure 6-8 Continuous Address Register Write Example Starting With Register 0x00 Using SPI With SS

Figure 6-8 Continuous Address Register Write Example Starting With Register 0x00 Using SPI With SS

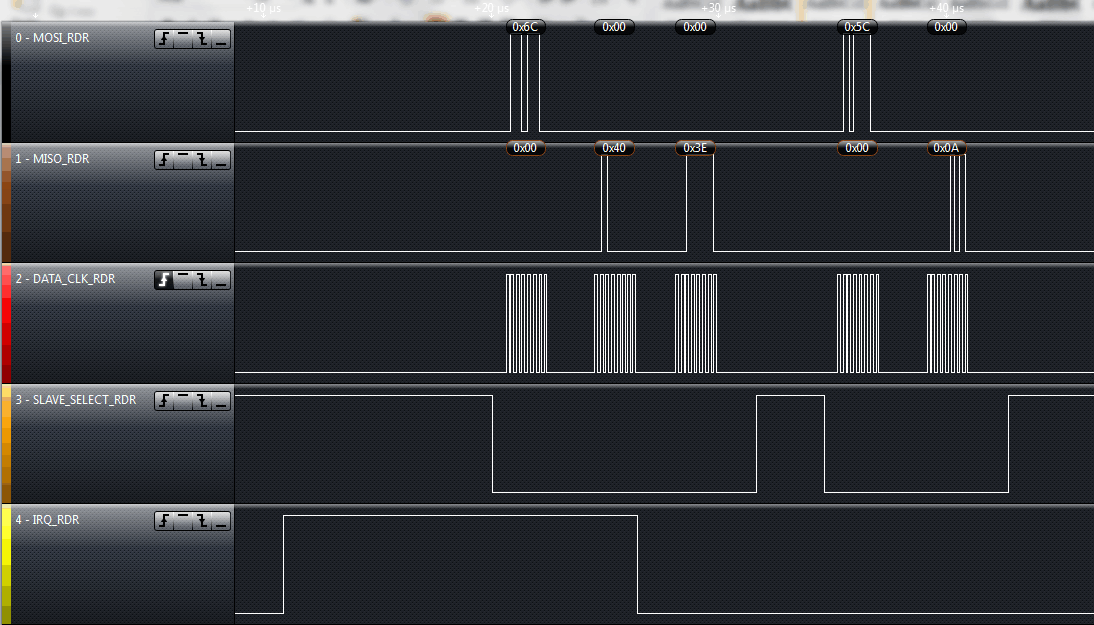

Figure 6-9 Continuous Address Register Read Example Starting With Register 0x00 Using SPI With SS

Figure 6-9 Continuous Address Register Read Example Starting With Register 0x00 Using SPI With SS

6.10.1.2 Noncontinuous Address Mode (Single Address Mode)

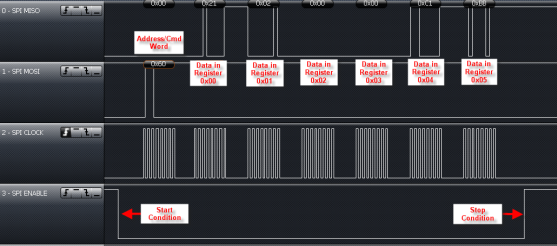

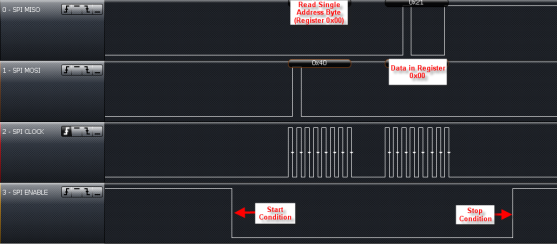

Table 6-12 summarizes the noncontinuous address (single address) mode communication. Figure 6-10 and Figure 6-11 show the signals between the MCU and the TRF7964A.

Table 6-12 Noncontinuous Address Mode (Single Address Mode)

| Start | Adr x | Data(x) | Adr y | Data(y) | ... | Adr z | Data(z) | StopSgl |

Figure 6-10 Single Address Register Write Example of Register 0x00 Using SPI With SS

Figure 6-10 Single Address Register Write Example of Register 0x00 Using SPI With SS

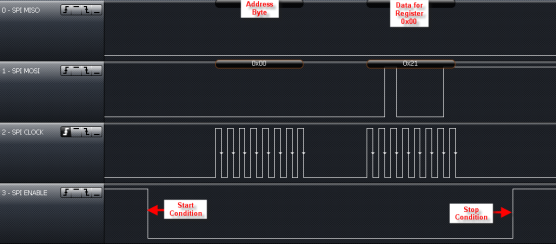

Figure 6-11 Single Address Register Read Example of Register 0x00 Using SPI With SS

Figure 6-11 Single Address Register Read Example of Register 0x00 Using SPI With SS

6.10.1.3 Direct Command Mode

Table 6-13 summarizes the direct command mode communication. Figure 6-12 shows the signals between the MCU and the TRF7964A.

Table 6-13 Direct Command Mode

| Start | Cmd x | (Optional data or command) | Stop |

Section 6.13 describes the other direct command codes from the MCU to the TRF7964A IC.

6.10.1.4 FIFO Operation

The FIFO is a 127-byte register at address 0x1F with byte storage locations 0 to 126. FIFO data is loaded in a cyclical manner and can be cleared by a reset command (0x0F) (see Figure 6-12 showing this direct command).

Associated with the FIFO are two counters and three FIFO status flags. The first counter is a 7-bit FIFO byte counter (bits B0 to B6 in register 0x1C) that tracks the number of bytes loaded into the FIFO. If the number of bytes in the FIFO is n, the register value is n (number of bytes in FIFO register). For example, if 8 bytes are in the FIFO, the FIFO counter (Register 0x1C) has the hexadecimal value of 0x08 (binary value of 00001000).

A second counter (12 bits wide) indicates the number of bytes being transmitted (registers 0x1D and 0x1E) in a data frame. An extension to the transmission-byte counter is a 4-bit broken-byte counter also provided in register 0x1E (bits B0 to B3). Together these counters make up the TX length value that determines when the reader generates the EOF byte.

During transmission, the FIFO is checked for an almost-empty condition, and during reception for an almost-full condition. The maximum number of bytes that can be loaded into the FIFO in a single sequence is 127 bytes.

NOTE

The number of bytes in a frame, transmitted or received, can be greater than 127 bytes.

During transmission, the MCU loads the TRF7964A FIFO (or during reception the MCU removes data from the FIFO), and the FIFO counter counts the number of bytes being loaded into the FIFO. Meanwhile, the byte counter keeps track of the number of bytes being transmitted. An interrupt request is generated if the number of bytes in the FIFO triggers the watermark levels, which are configured in the Adjustable FIFO IRQ Levels register (0x14). The default setting is for the interrupt to be triggered when receiving 124 bytes during RX or having 4 bytes remaining during TX. These watermark levels are used so that MCU can send new data or read the data as necessary. The MCU must also validate the number of data bytes to be sent, so as to not surpass the value defined in the TX Length Byte registers (0x1D and 0x1E). The MCU also signals the transmit logic when the last byte of data is sent or was removed from the FIFO during reception.

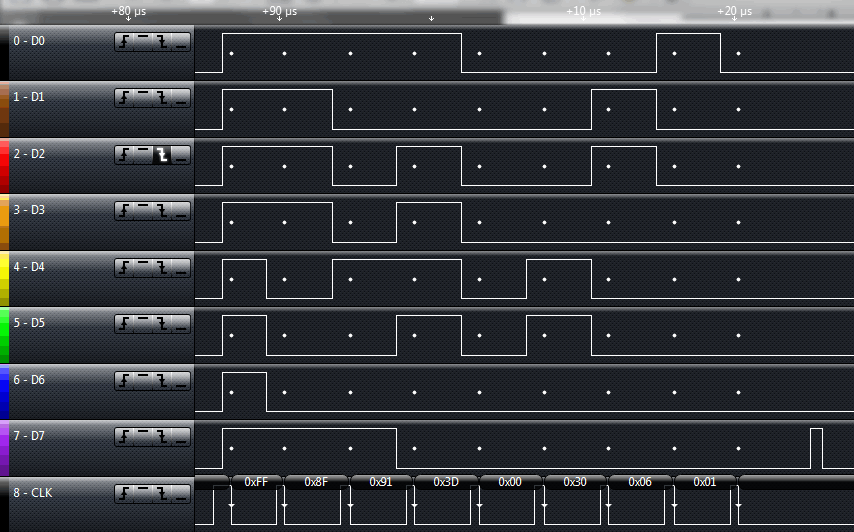

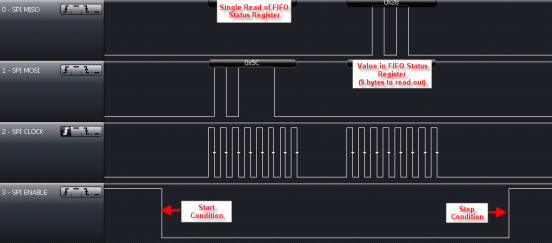

Figure 6-13 shows an example of checking the FIFO Status register using SPI with SS.

Figure 6-13 Example of Checking the FIFO Status Register Using SPI With SS

Figure 6-13 Example of Checking the FIFO Status Register Using SPI With SS

6.10.2 Parallel Interface Mode

In parallel mode, the start condition is generated on the rising edge of the I/O_7 pin while the CLK is high.

This is used to reset the interface logic. Figure 6-14, Figure 6-15, and Figure 6-16 show the sequence of the data, with an 8-bit address word first, followed by data.

Communication is ended by:

- The StopSmpl condition, where a falling edge on the I/O_7 pin is expected while CLK is high.

- The StopCont condition, where the I/O_7 pin must have a successive rising and falling edge while CLK is low to reset the parallel interface and be ready for the new communication sequence.

- The StopSmpl condition is also used to terminate the direct mode.

Figure 6-14 Parallel Interface Communication With Simple Stop Condition (StopSmpl)

Figure 6-14 Parallel Interface Communication With Simple Stop Condition (StopSmpl)

Figure 6-15 Parallel Interface Communication With Continuous Stop Condition (StopCont)

Figure 6-15 Parallel Interface Communication With Continuous Stop Condition (StopCont)

6.10.3 Reception of Air Interface Data

At the start of a receive operation (when SOF is successfully detected), B6 is set in the IRQ Status register. An RX complete interrupt request is sent to the MCU at the end of the receive operation if the receive data string is shorter than or equal to the number of bytes configured in the Adjustable FIFO IRQ Levels register (0x14). An IRQ_FIFO interrupt request is sent to the MCU during the receive operation if the data string is greater than the level set in the Adjustable FIFO IRQ Levels register (0x14). After receiving an IRQ_FIFO or RX complete interrupt, the MCU must read the FIFO Status register (0x1C) to determine the number of bytes to be read from the FIFO. Next, the MCU must read the data in the FIFO. It is optional but recommended to read the FIFO Status register (0x1C) after reading FIFO data to determine if the receive is complete. In the case of an IRQ_FIFO, the MCU should expect either another IRQ_FIFO or RX complete interrupt. This is repeated until an RX complete interrupt is generated. The MCU receives the interrupt request, then checks to determine the reason for the interrupt by reading the IRQ Status register (0x0C), after which the MCU reads the data from the FIFO.

If the reader detects a receive error, the corresponding error flag is set (framing error, CRC error) in the IRQ Status register, indicating to the MCU that reception was not completed correctly.

6.10.4 Data Transmission From MCU to TRF7964A

Before beginning data transmission, the FIFO should always be cleared with a reset command (0x0F). Data transmission is initiated with a selected command (see Section 6.13). The MCU then commands the reader to do a continuous write command (0x3D) starting from register 0x1D. Data written into register 0x1D is the TX Length Byte 1 (upper and middle nibbles), while the following byte in register 0x1E is the TX Length Byte 2 (lower nibble and broken byte length) (see Table 6-47 and Table 6-48) . Note that the TX byte length determines when the reader sends the end of frame (EOF) byte. After the TX length bytes are written, FIFO data is loaded in register 0x1F with byte storage locations 0 to 127. Data transmission begins automatically after the first byte is written into the FIFO. The loading of TX length bytes and the FIFO can be done with a continuous-write command, as the addresses are sequential.

At the start of transmission, the flag B7 (IRQ_TX) is set in the IRQ Status register, and at the end of the transmit operation, an interrupt is sent to inform the MCU that the task is complete.

6.10.5 Serial Interface Communication (SPI)

When an SPI interface is used, I/O pins I/O_2, I/O_1, and I/O_0 must be hard wired according to Table 6-9. On power up, the TRF7964A looks for the status of these pins and then enters into the corresponding mode.

The serial communications work in the same manner as the parallel communications with respect to the FIFO, except for the following condition. On receiving an IRQ from the reader, the MCU reads the TRF7964A IRQ Status register to determine how to service the reader. After this, the MCU must to do a dummy read to clear the reader's IRQ status register. The dummy read is required in SPI mode because the reader's IRQ status register needs an additional clock cycle to clear the register. This is not required in parallel mode because the additional clock cycle is included in the Stop condition. When first establishing communications with the TRF7964A, the SOFT_INIT (0x03) and IDLE (0x00) commands should be sent first from the MCU (see Table 6-14).

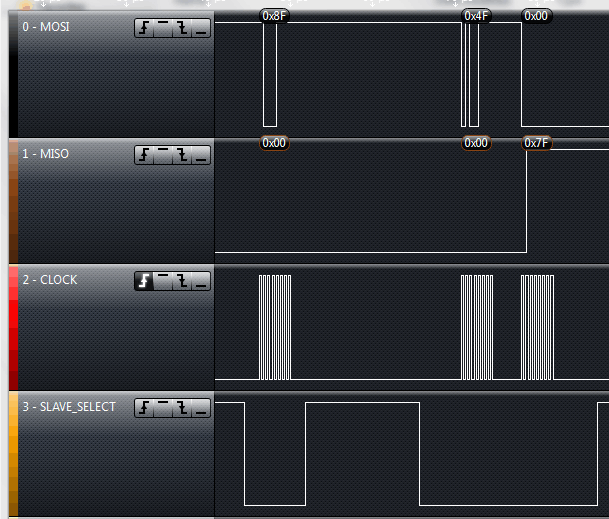

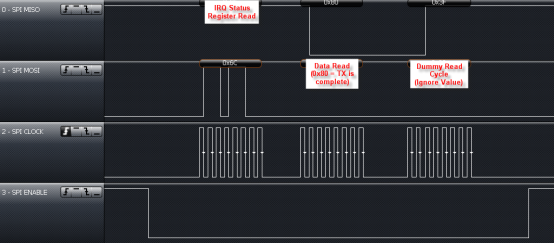

The procedure for a dummy read is as follows (see Figure 6-17 and Figure 6-18):

- Start the dummy read:

- When using slave select (SS): set SS bit low.

- When not using SS: start condition is when Data Clock is high (see Table 6-9).

- Send address word to IRQ status register (0x0C) with read and continuous address mode bits set to 1 (see Table 6-9).

- Read 1 byte (8 bits) from IRQ status register (0x0C).

- Dummy-read 1 byte from register 0x0D (collision position and interrupt mask).

- Stop the dummy read:

- When using slave select (SS): set SS bit high.

- When not using SS: stop condition when Data Clock is high.

Figure 6-17 Procedure for Dummy Read

Figure 6-17 Procedure for Dummy Read

Figure 6-18 Example of Dummy Read Using SPI With SS

Figure 6-18 Example of Dummy Read Using SPI With SS

6.10.5.1 Serial Interface Mode With Slave Select (SS)

The serial interface is in reset while the Slave Select signal is high. Serial data in (MOSI) changes on the rising edge, and is validated in the reader on the falling edge, as shown in Figure 6-19. Communication is terminated when the Slave Select signal goes high.

All words must be 8 bits long with the MSB transmitted first.

Figure 6-19 SPI With Slave Select Timing Diagram

Figure 6-19 SPI With Slave Select Timing Diagram

The read command is sent out on the MOSI pin, MSB first, in the first eight clock cycles. MOSI data changes on the rising edge, and is validated in the reader on the falling edge, as shown in Figure 6-19. During the write cycle, the serial data out (MISO) is not valid. After the last read command bit (B0) is validated at the eighth falling edge of SCLK, valid data can be read on the MISO pin at the falling edge of SCLK. It takes eight clock edges to read out the full byte (MSB first). See Section 5.4 for electrical specifications related to Figure 6-19.

Figure 6-20 and Figure 6-21 show the continuous read operation.

Figure 6-20 Continuous Read Operation Using SPI With Slave Select

Figure 6-20 Continuous Read Operation Using SPI With Slave Select

Figure 6-21 Continuous Read of Registers 0x00 to 0x05 Using SPI With SS

Figure 6-21 Continuous Read of Registers 0x00 to 0x05 Using SPI With SS

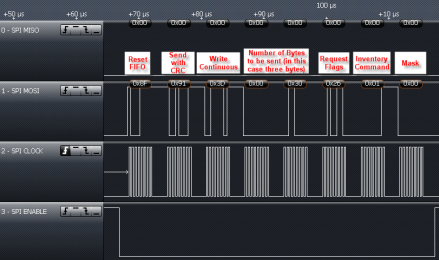

Figure 6-22 shows an example of performing a single slot inventory command. Reader registers (in this example) are configured for 5 VDC in and default operation.

Figure 6-22 Inventory Command Sent From MCU to TRF7964A

Figure 6-22 Inventory Command Sent From MCU to TRF7964A

The TRF7964A takes these bytes from the MCU and then send out Request Flags, Inventory Command, and Mask over the air to the ISO/IEC 15693 transponder. After these three bytes have been transmitted, an interrupt occurs to indicate back to the reader that the transmission has been completed. In the example in Figure 6-23, this IRQ occurs approximately 1.6 ms after the SS line goes high after the Inventory command is sent out.

The IRQ status register read (0x6C) yields 0x80, which indicates that TX is indeed complete. This is followed by a dummy clock. Then, if a tag is in the field and no error is detected by the reader, a second interrupt is expected and occurs (in this example) approximately 4 ms after first IRQ is read and cleared.

In the continuation of the example (see Figure 6-24), the IRQ Status Register is read using method previously recommended, followed by a single read of the FIFO Status register, which indicates that there are 10 bytes to be read out.

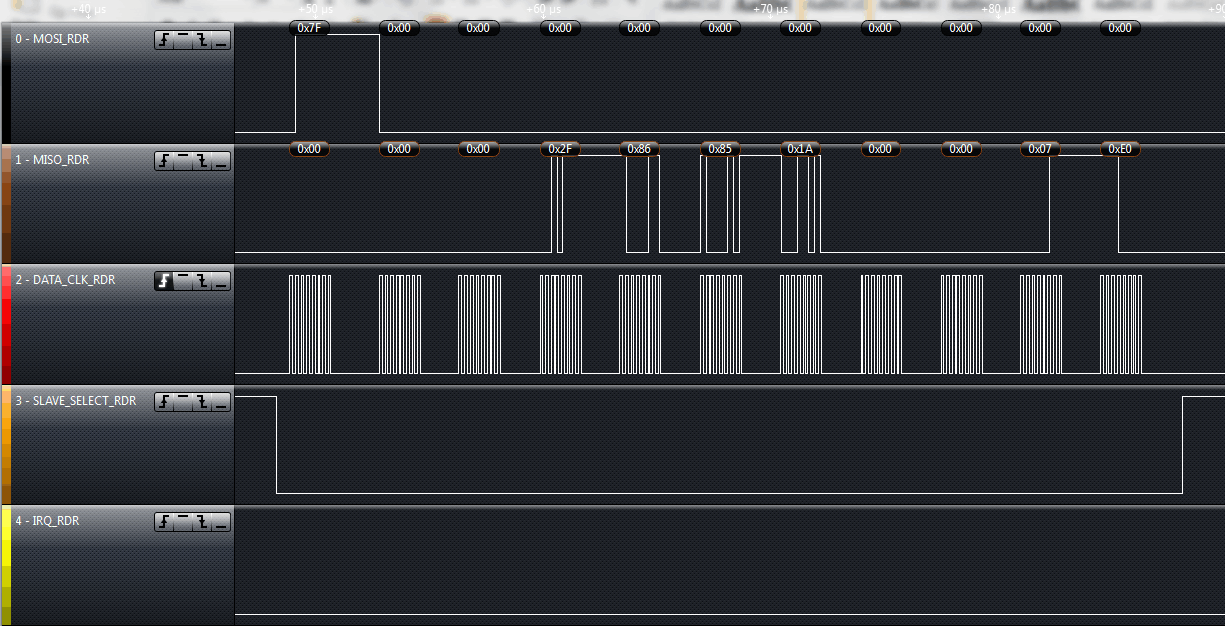

This is then followed by a continuous read of the FIFO (see Figure 6-25). The first byte is (and should be) 0x00 for no error. The next byte is the DSFID (usually shipped by manufacturer as 0x00), then the UID, shown here up to the next most significant byte, the MFG code [shown as 0x07 (TI silicon)].

TI recommends resetting the FIFO after receiving data. Additionally, the RSSI value of the tag can be read out at this point. In the example in Figure 6-26, the transponder is very close to the antenna, so value of 0x7F is recovered.

6.10.6 Direct Mode

Direct mode allows the user to configure the reader in one of two ways. Direct mode 0 (bit 6 = 0, as defined in ISO Control register) allows the user to use only the front-end functions of the reader, bypassing the protocol implementation in the reader. For transmit functions, the user has direct access to the transmit modulator through the MOD pin (pin 14). On the receive side, the user has direct access to the subcarrier signal (digitized RF envelope signal) on I/O_6 (pin 23).

Direct mode 1 (bit 6 = 1, as defined in ISO Control register) uses the subcarrier signal decoder of the selected protocol (as defined in ISO Control register). This means that the receive output is not the subcarrier signal but the decoded serial bit stream and bit clock signals. The serial data is available on I/O_6 (pin 23) and the bit clock is available on I/O_5 (pin 22). The transmit side is identical; the user has direct control over the RF modulation through the MOD input. This mode is provided so that the user can implement a protocol that has the same bit coding as one of the protocols implemented in the reader, but needs a different framing format.

To select direct mode, the user must first choose which direct mode to enter by writing B6 in the ISO Control register. This bit determines if the receive output is the direct subcarrier signal (B6 = 0) or the serial data of the selected decoder. If B6 = 1, then the user must also define which protocol should be used for bit decoding by writing the appropriate setting in the ISO Control register.

The reader actually enters the direct mode when B6 (direct) is set to 1 in the chip status control register. Direct mode starts immediately. The write command should not be terminated with a stop condition (see communication protocol), because the stop condition terminates the direct mode and clears B6. This is necessary as the direct mode uses one or two I/O pins (I/O_6, I/O_5). Normal parallel communication is not possible in direct mode. Sending a stop condition terminates direct mode.

NOTE

An additional direct mode known as special direct mode can be used to communicate with certain tags not compliant with ISO standards. For full details on how to use this feature, see Using Special Direct Mode With the TRF7970A.

Figure 6-27 shows the different configurations available in direct mode.

- In mode 0, the reader is used as an AFE only, and protocol handling is bypassed.

- In mode 1, framing is not done, but SOF and EOF are present. This allows for a user-selectable framing level based on an existing ISO standard.

- In mode 2, data is ISO-standard formatted. SOF, EOF, and error checking are removed, so the microprocessor receives only bytes of raw data through a 127-byte FIFO.

Figure 6-27 User-Configurable Modes

Figure 6-27 User-Configurable Modes

The steps to enter direct mode are listed below, using SPI with SS communication method only as one example, as direct modes are also possible with parallel and SPI without SS. The must enter direct mode 0 to accommodate card type communications that are not compliant with ISO standards. Direct mode can be entered at any time, so if a card type started with ISO standard communications, then deviated from the standard after being identified and selected, the ability to go into direct mode 0 is very useful.

Step 1: Configure Pins I/O_0 to I/O_2 for SPI with SS

Step 2: Set Pin 12 of the TRF7964A (ASK/OOK pin) to 0 for ASK or 1 for OOK

Step 3: Program the TRF7964A registers

The following registers must be explicitly set before going into the direct mode.

- ISO Control register (0x01) to the appropriate standard

- Modulator and SYS_CLK register (0x09) to the appropriate clock speed and modulation

- 0x21 for 6.78 MHz Clock and OOK (100%) modulation

- 0x20 for 6.78 MHz Clock and ASK 10% modulation

- 0x22 for 6.78 MHz Clock and ASK 7% modulation

- 0x23 for 6.78 MHz Clock and ASK 8.5% modulation

- 0x24 for 6.78 MHz Clock and ASK 13% modulation

- 0x25 for 6.78 MHz Clock and ASK 16% modulation

(See register 0x09 definition for all other possible values)

Example register setting for ISO/IEC 14443 A at 106 kbps:

- ISO Control register (0x01) to 0x08

- RX No Response Wait Time register (0x07) to 0x0E

- RX Wait Time register (0x08) to 0x07

- Modulator control register (0x09) to 0x21 (or any custom modulation)

- RX Special Settings register (0x0A) to 0x20

Step 4: Entering Direct Mode 0

The following registers must be programmed to enter direct mode 0:

- Set bit B6 of the Modulator and SYS_CLK Control register (0x09) to 1.

- Set bit B6 of the ISO Control (Register 01) to 0 for direct mode 0 (default its 0)

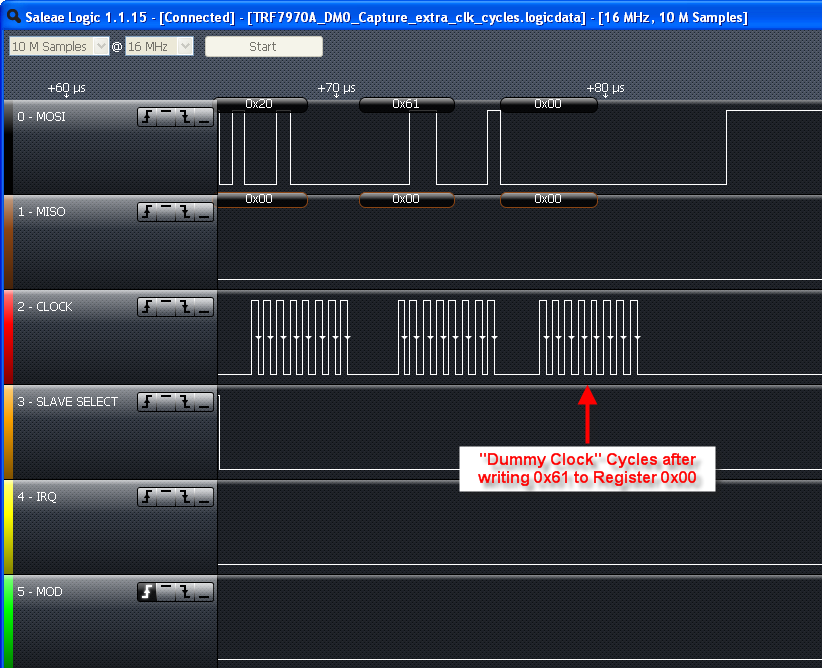

- Set bit B6 of the Chip Status Control register (0x00) to 1 to enter direct mode

- Send extra eight clock cycles (see Figure 6-28, this step is TRF7964A specific)

- It is important that the last write is not terminated with a stop condition. For SPI, this means that Slave Select (I/O_4) stays low.

- Sending a Stop condition terminates the direct mode and clears bit B6 in the Chip Status Control register (0x00).

NOTE

NOTE

Access to Registers, FIFO, and IRQ is not available during direct mode 0.

The reader enters the direct mode 0 when bit 6 of the Chip Status Control register (0x00) is set to a 1 and stays in direct mode 0 until a stop condition is sent from the microcontroller.

NOTE

The write command should not be terminated with a stop condition (for example, in SPI mode this is done by bringing the Slave Select line high after the register write), because the stop condition terminates the direct mode and clears bit 6 of the Chip Status Control register (0x00), making it a 0.

Figure 6-28 Entering Direct Mode 0

Figure 6-28 Entering Direct Mode 0

Step 5: Transmit Data Using Direct Mode

The application now has direct control over the RF modulation through the MOD input (see Figure 6-29).

Figure 6-29 Direct Control Signals

Figure 6-29 Direct Control Signals

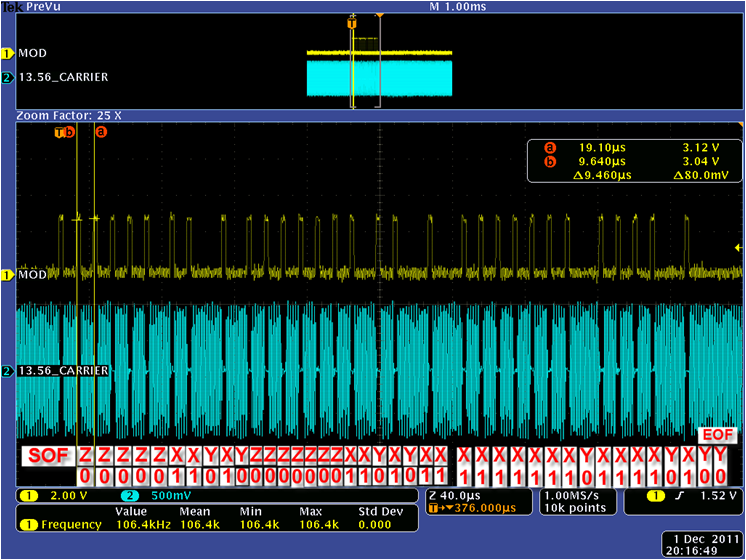

The microcontroller is responsible for generating data according to the coding specified by the particular standard. The microcontroller must generate SOF, EOF, Data, and CRC. In direct mode, the FIFO is not used and no IRQs are generated. See the applicable ISO standard to understand bit and frame definitions. Figure 6-30 shows an example of what the developer sees when using DM0 in an actual application. This figure clearly shows the relationship between the MOD pin being controlled by the MCU and the resulting modulated 13.56-MHz carrier signal.

Figure 6-30 TX Sequence Out in DM0

Figure 6-30 TX Sequence Out in DM0

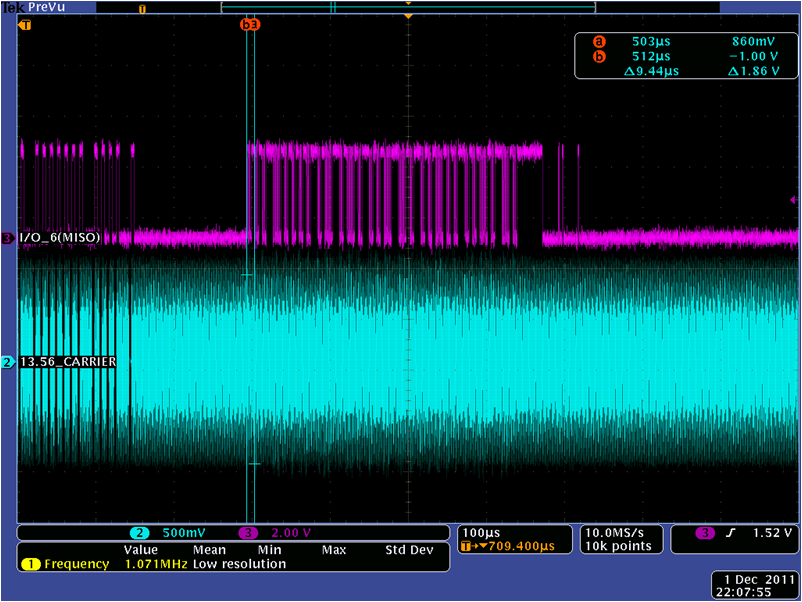

Step 6: Receive Data Using Direct Mode

After the TX operation is complete, the tag responds to the request and the subcarrier data is available on pin I/O_6. The microcontroller needs to decode the subcarrier signal according to the standard. This includes decoding the SOF, data bits, CRC, and EOF. The CRC then needs to be checked to verify data integrity. The receive data bytes must be buffered locally.

As an example of the receive data bits and framing level according to the ISO/IEC 14443 A standard is shown in Figure 6-31 (taken from ISO/IEC 14443 specification and TRF7964A air interface).

Figure 6-31 Receive Data Bits and Framing Level

Figure 6-31 Receive Data Bits and Framing Level

Figure 6-32 shows an example of what the developer should expect on the I/O_6 line during the RX process while in direct mode 0.

Figure 6-32 RX Sequence on I/O_6 in DM0 (Analog Capture)

Figure 6-32 RX Sequence on I/O_6 in DM0 (Analog Capture)

Step 7: Terminating Direct Mode 0

After the EOF is received, data transmission is over, and direct mode 0 can be terminated by sending a Stop Condition (in the case of SPI, make the Slave Select go high). The TRF7964A is returned to default state.

6.11 TRF7964A Initialization

To properly initialize the TRF7964A, perform these steps:

- Raise the EN, EN2, and SS lines at the correct intervals after power up (for timing diagrams, see Figure 6-3 and Figure 6-4).

- Issue a Software Initialization direct command (0x03), followed by an Idle direct command (0x00) to soft reset the TRF7964A.

- Delay 1 ms to allow the TRF7964A to fully process the soft reset.

- Issue a Reset FIFO direct command (0x0F).

- Write the Modulator and SYS_CLK Control register (0x09) with the appropriate application-specific setting for the crystal and system clock settings.

- (Optional) Write the Regulator and I/O Control register (0x0B) with the appropriate application-specific setting.

NOTE

Table 6-16 lists the initial register settings for the TRF7964A after the Software Initialization command.

6.12 Special Direct Mode for Improved MIFARE™ Compatibility

6.13 Direct Commands from MCU to Reader

6.13.1 Command Codes

Table 6-14 summarizes the command codes.

Table 6-14 Address and Command Word Bit Distribution

The command code values from Table 6-14 are substituted in Table 6-15, bits 0 through 4. Also, the most-significant bit (MSB) in Table 6-15 must be set to 1. (Table 6-15 is same as Table 6-10, shown here again for easy reference).

Table 6-15 Address and Command Word Bit Distribution

| BIT | DESCRIPTION | BIT FUNCTION | ADDRESS | COMMAND |

|---|---|---|---|---|

| B7 | Command control bit | 0 = Address 1 = Command |

0 | 1 |

| B6 | Read/Write | 0 = Write 1 = Read |

R/W | 0 |

| B5 | Continuous address mode | 1 = Continuous mode | R/W | 0 |

| B4 | Address/Command bit 4 | Adr 4 | Cmd 4 | |

| B3 | Address/Command bit 3 | Adr 3 | Cmd 3 | |

| B2 | Address/Command bit 2 | Adr 2 | Cmd 2 | |

| B1 | Address/Command bit 1 | Adr 1 | Cmd 1 | |

| B0 | Address/Command bit 0 | Adr 0 | Cmd 0 |

The MSB determines if the word is to be used as a command or address. The last two columns of Table 6-15 show the function of each bit, depending on whether address or command is written. Command mode is used to enter a command resulting in reader action (initialize transmission, enable reader, and turn reader on or off).

6.13.1.1 Idle (0x00)

This command issues dummy clock cycles. In parallel mode, one cycle is issued. In SPI mode, eight cycles are issued. This command should be sent after a Software Initialization command to allow the command to finish operation.

6.13.1.2 Software Initialization (0x03)

This command starts a power-on reset. After sending this command, the register values change as shown in Table 6-16.

Table 6-16 Register Values After Sending Software Initialization (0x03)

| ADDRESS | REGISTER | VALUE |

|---|---|---|

| 0x00 | Chip status control | 0x01 |

| 0x01 | ISO control | 0x21(1) |

| 0x02 | ISO/IEC 14443 B TX options | 0x00 |

| 0x03 | ISO/IEC 14443 A high bit rate options | 0x00 |

| 0x04 | TX timer high byte control | 0xC1(1) |

| 0x05 | TX timer low byte control | 0xC1(1) |

| 0x06 | TX pulse length control | 0x00 |

| 0x07 | RX no response wait time | 0x0E |

| 0x08 | RX wait time | 0x07(1) |

| 0x09 | Modulator and SYS_CLK control | 0x91 |

| 0x0A | RX special setting | 0x10(1) |

| 0x0B | Regulator and I/O control | 0x87 |

| 0x0C | IRQ status | 0x00 |

| 0x0D | Collision position and interrupt mask | 0x3E |

| 0x0E | Collision position | 0x00 |

| 0x0F | RSSI levels and oscillator status | 0x40 |

| 0x10 | Special function | 0x00 |

| 0x11 | Special function | 0x00 |

| 0x12 | RAM | 0x00 |

| 0x13 | RAM | 0x00 |

| 0x14 | Adjustable FIFO IRQ levels | 0x00 |

| 0x1A | Test | 0x00 |

| 0x1B | Test | 0x00 |

| 0x1C | FIFO status | 0x00 |

6.13.1.3 Reset FIFO (0x0F)

The reset command clears the FIFO contents and FIFO Status register (0x1C). It also clears the register storing the collision error location (0x0E).

6.13.1.4 Transmission With CRC (0x11)

The transmission command must be sent first, followed by transmission length bytes, and FIFO data. The reader starts transmitting after the first byte is loaded into the FIFO. The CRC byte is included in the transmitted sequence.

6.13.1.5 Transmission Without CRC (0x10)

Same as Section 6.13.1.4 with CRC excluded.

6.13.1.6 Delayed Transmission With CRC (0x13)

The transmission command must be sent first, followed by the transmission length bytes, and FIFO data.

The reader transmission is triggered by the TX timer.

6.13.1.7 Delayed Transmission Without CRC (0x12)

Same as Section 6.13.1.6 with CRC excluded.

6.13.1.8 Transmit Next Time Slot (0x14)

When this command is received, the reader transmits the next slot command. The next slot sign is defined by the protocol selection. This is used by the ISO/IEC 15693 protocol.

6.13.1.9 Block Receiver (0x16)

The block receiver command puts the digital part of receiver (bit decoder and framer) in reset mode. This is useful in an extremely noisy environment, where the noise level could otherwise cause a constant switching of the subcarrier input of the digital part of the receiver. The receiver (if not in reset) would try to catch a SOF signal, and if the noise pattern matched the SOF pattern, an interrupt would be generated, falsely signaling the start of an RX operation. A constant flow of interrupt requests can be a problem for the external system (MCU), so the external system can stop this by putting the receive decoders in reset mode. The reset mode can be terminated in two ways. The external system can send the enable receiver command. The reset mode is also automatically terminated at the end of a TX operation. The receiver can stay in reset after end of TX if the RX wait time register (0x08) is set. In this case, the receiver is enabled at the end of the wait time following the transmit operation.

6.13.1.10 Enable Receiver (0x17)

This command clears the reset mode in the digital part of the receiver if the reset mode was entered by the block receiver command.

6.13.1.11 Test Internal RF (RSSI at RX Input With TX ON) (0x18)

The level of the RF carrier at RF_IN1 and RF_IN2 inputs is measured. Operating range between 300 mVP and 2.1 VP (step size is 300 mV). The two values are displayed in the RSSI Levels and Oscillator Status register (0x0F). The command is intended for diagnostic purposes to set correct RF_IN levels. Optimum RFIN input level is approximately 1.6 VP or code 5 to 6. The nominal relationship between the RF peak level and RSSI code is shown in Table 6-17 and in Section 6.5.1.1.

NOTE

If the command is executed immediately after power-up and before any communication with a tag is performed, the command must be preceded by Enable RX command. The Check RF commands require full operation, so the receiver must be activated by Enable RX or by a normal Tag communication for the Check RF command to work properly.

Table 6-17 Test Internal RF Peak Level to RSSI Codes

| RF_IN1 [mVPP] | 300 | 600 | 900 | 1200 | 1500 | 1800 | 2100 |

| Decimal Code | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Binary Code | 001 | 010 | 011 | 001 | 101 | 011 | 111 |

6.13.1.12 Test External RF (RSSI at RX Input with TX OFF) (0x19)

This command can be used in active mode when the RF receiver is switched on but RF output is switched off. This means bit B1 = 1 in Chip Status Control Register. The level of RF signal received on the antenna is measured and displayed in the RSSI Levels and Oscillator Status register (0x0F). The relation between the 3 bit code and the external RF field strength [A/m] must be determinate by calculation or by experiments for each antenna type as the antenna Q and connection to the RF input influence the result. The nominal relation between the RF peak to peak voltage in the RF_IN1 input and RSSI code is shown in Table 6-18 and in Section 6.5.1.2.

NOTE

If the command is executed immediately after power-up and before any communication with a tag is performed, the command must be preceded by an Enable RX command. The Check RF commands require full operation, so the receiver must be activated by Enable RX or by a normal Tag communication for the Check RF command to work properly.

Table 6-18 Test External RF Peak Level to RSSI Codes

| RF_IN1 [mVPP] | 40 | 60 | 80 | 100 | 140 | 180 | 300 |