ZHCSTJ0 October 2023 DLP651LE

PRODUCTION DATA

- 1

- 1 特性

- 2 应用

- 3 说明

- 4 Revision History

- 5 Pin Configuration and Functions

-

6 Specifications

- 6.1 Absolute Maximum Ratings

- 6.2 Storage Conditions

- 6.3 ESD Ratings

- 6.4 Recommended Operating Conditions

- 6.5 Thermal Information

- 6.6 Electrical Characteristics

- 6.7 Timing Requirements

- 6.8 System Mounting Interface Loads

- 6.9 Micromirror Array Physical Characteristics

- 6.10 Micromirror Array Optical Characteristics

- 6.11 Window Characteristics

- 6.12 Chipset Component Usage Specification

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3 Feature Description

- 7.4 Optical Interface and System Image Quality Considerations

- 7.5 Micromirror Array Temperature Calculation

- 7.6 Micromirror Power Density Calculation

- 7.7 Window Aperture Illumination Overfill Calculation

- 7.8 Micromirror Landed-On/Landed-Off Duty Cycle

- 8 Application and Implementation

- 9 Layout

- 10Power Supply Recommendations

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

7.7 Window Aperture Illumination Overfill Calculation

The amount of optical overfill on the critical area of the window aperture cannot be measured directly. For systems with uniform illumination on the array the amount is determined using the total measured incident optical power on the DMD, and the ratio of the total optical power on the DMD that is on the defined critical area. The optical model is used to determine the percent of optical power on the window aperture critical area and estimate the size of the area.

- QAP-ILL = [QINCIDENT × OPAP_ILL_RATIO] ÷ AAP_ILL (W/cm2)

where:

- QAP-ILL = window aperture illumination overfill (W/cm2)

- QINCIDENT = total incident optical power on the DMD (Watts) (measured)

- OPAP_ILL_RATIO = ratio of the optical power on the critical area of the window aperture to the total optical power on the DMD (optical model)

- AAP-ILL = size of the window aperture critical area (cm2) (datasheet)

- OPCA_RATIO = percent of the window aperture critical area with incident optical power (%) (optical model)

Sample calculation:

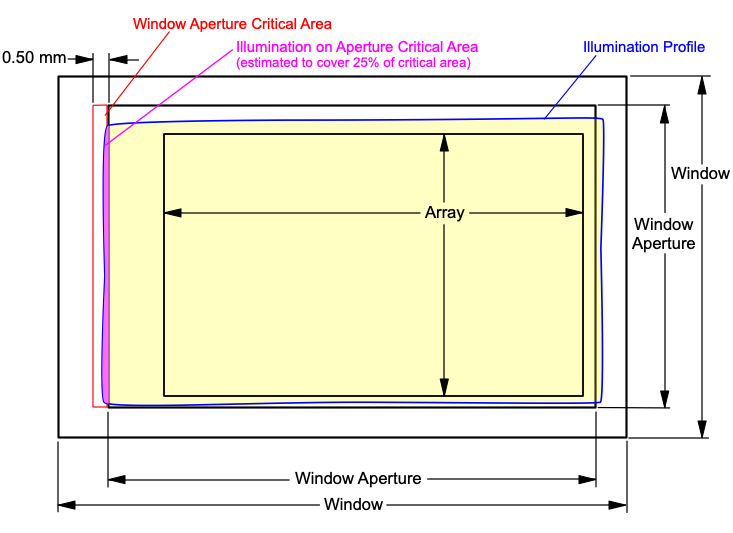

Figure 7-2 Window Aperture Overfill Example

Figure 7-2 Window Aperture Overfill Example See the figure for the length of the critical aperture.

Equation 18. QINCIDENT = 45 W (measured)

Equation 19. OPAP_ILL_RATIO = 0.312% (optical model)

Equation 20. OVCA_RATIO = 25% (optical model)

Equation 21. Length of the window aperture for critical area = 0.9997 (data sheet)

Equation 22. Width of critical area = 0.050 cm (data sheet)

Equation 23. AAP-ILL = 0.99977 cm × 0.050 cm = 0.049989 (cm2)

Equation 24. QAP-ILL = (45 × 0.00312) ÷ (0.049989 × 0.25) = 11.2 (W/cm2)