DLPU137 April 2024

- 1

- Description

- Features

- Applications

- 5

- 1Evaluation Module Overview

- 2Hardware

- 3Software

- 4Hardware Design Files

- 5Additional Information

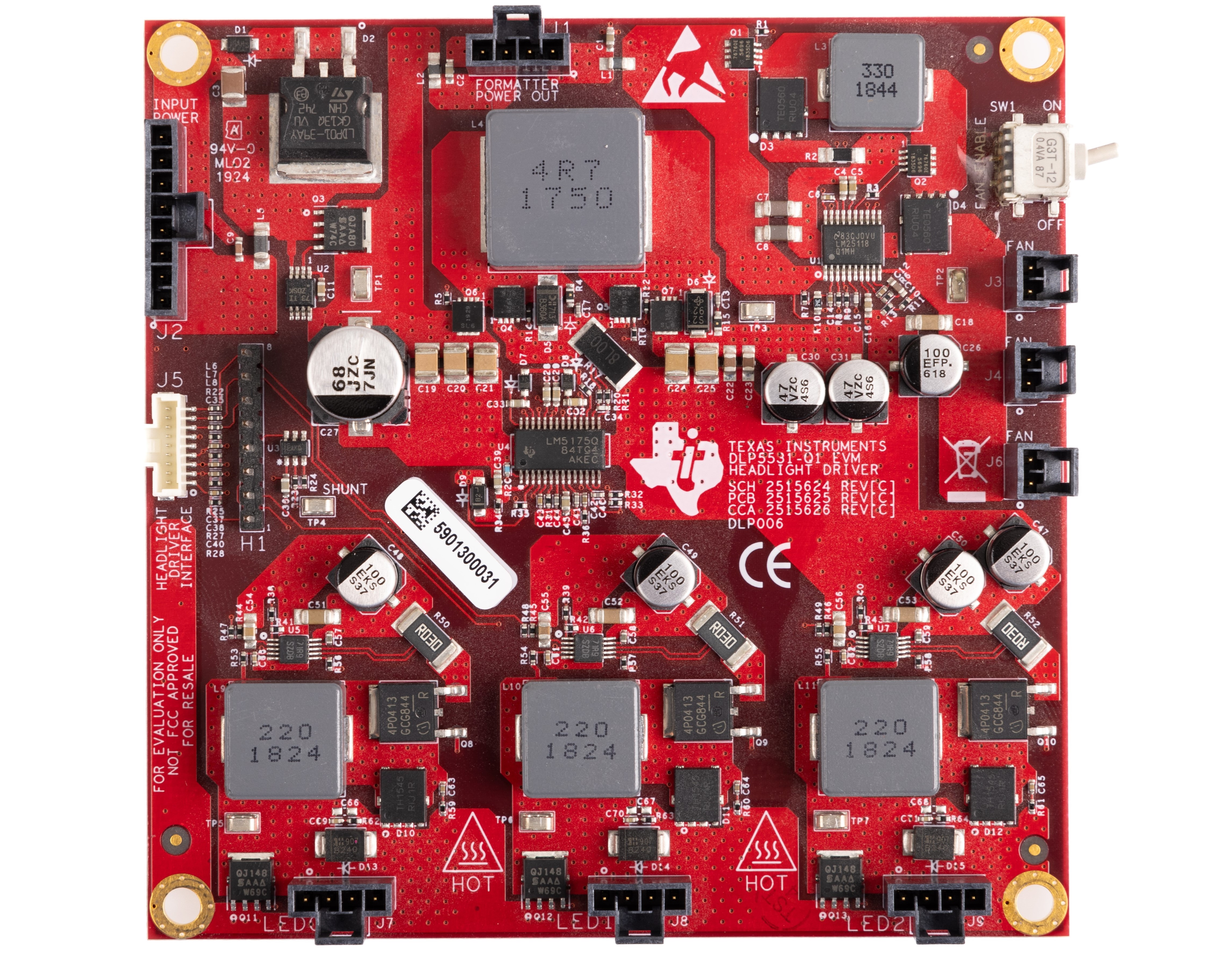

2.6 LED Driver PCB - DLP4621Q1EVM

The DLP4621Q1EVM can be used as a standalone system with just the controller and DMD boards, but can be combined with an LED driver board. The LED driver board shown in Figure 3-6 is designed for monochrome (white light) designs. The LED brightness can be controlled through PWM output from the DLPC231-Q1. Using the Automotive Control Program reference software Headlight Control tab, the PWM slider bars (PWM0, PWM1, and PWM2) control the current through each LED driver channel. Note that the PWM control can exceed the maximum current specification of some LEDs in certain LED configurations.

The LED driver can reach temperatures above 55°C without proper cooling and airflow. Contact can cause burns! |

LED drivers (J7, J8, J9) can produce high currents up to 8A. Do not remove these headers, and do not touch the contact points during operation! |

Figure 2-6 LED Driver PCB - DLP4621Q1EVM

Figure 2-6 LED Driver PCB - DLP4621Q1EVMThe LED driver PCB contains the ports listed in Table 3-7.

| SCHEMATIC REFERENCE | FUNCTION |

|---|---|

| J1 | Controller power |

| J2 | Input power |

| J3 | Fan |

| J4 | Fan |

| J5 | Headlight driver interface |

| J6 | Fan |

| J7 | LED0 - High current output up to 8A, locking connector |

| J8 | LED1 - High current output up to 8A, locking connector |

| J9 | LED2 - High current output up to 8A, locking connector |

The LED driver PCB contains the following ports and switches. SeeTable 3-8.

|

Schematic Reference / Signal Number |

PIN1 |

|---|---|

| SW1 |

Fan enable On position is down in Figure 3-6 |