SNVS774Q May 2004 – June 2020 LM117 , LM317-N

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Device Comparison Table

- 6 Pin Configuration and Functions

- 7 Specifications

- 8 Detailed Description

-

9 Application and Implementation

- 9.1 Application Information

- 9.2

Typical Applications

- 9.2.1 1.25-V to 25-V Adjustable Regulator

- 9.2.2 5-V Logic Regulator With Electronic Shutdown

- 9.2.3 Slow Turnon 15-V Regulator

- 9.2.4 Adjustable Regulator With Improved Ripple Rejection

- 9.2.5 High Stability 10-V Regulator

- 9.2.6 High-Current Adjustable Regulator

- 9.2.7 Emitter-Follower Current Amplifier

- 9.2.8 1-A Current Regulator

- 9.2.9 Common-Emitter Amplifier

- 9.2.10 Low-Cost 3-A Switching Regulator

- 9.2.11 Current-Limited Voltage Regulator

- 9.2.12 Adjusting Multiple On-Card Regulators With Single Control

- 9.2.13 AC Voltage Regulator

- 9.2.14 12-V Battery Charger

- 9.2.15 Adjustable 4-A Regulator

- 9.2.16 Current-Limited 6-V Charger

- 9.2.17 Digitally Selected Outputs

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

11.1.1.2.2 Heatsinking the TO-263 (KTT) Package

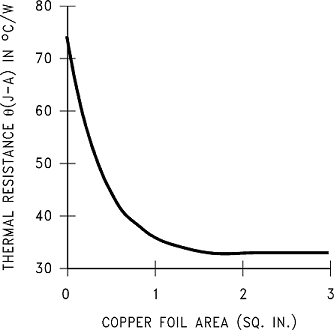

Figure 39 shows for the TO-263 the measured values of RθJA for different copper area sizes using a typical PCB with 1-oz. copper and no solder mask over the copper area used for heatsinking.

As shown in Figure 39, increasing the copper area beyond 1 square inch produces very little improvement. It must also be observed that the minimum value of RθJA for the TO-263 package mounted to a PCB is 32°C/W.

Figure 39. RθJA vs Copper (1-oz.) Area for the TO-263 Package

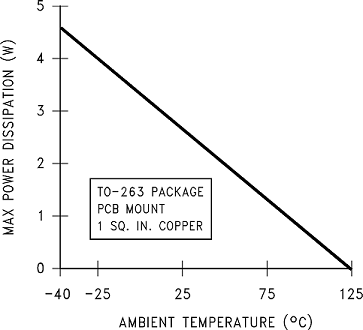

Figure 39. RθJA vs Copper (1-oz.) Area for the TO-263 Package As a design aid, Figure 40 shows the maximum allowable power dissipation compared to ambient temperature for the TO-263 device (assuming RθJA is 35°C/W and the maximum junction temperature is 125°C).

Figure 40. Maximum Power Dissipation vs TAMB for the TO-263 Package

Figure 40. Maximum Power Dissipation vs TAMB for the TO-263 Package