SSZTCY8 August 2023 DRV401 , INA228 , INA241A , LM2904 , TMCS1123

In electric vehicle (EV) charging and solar inverter systems, current sensors measure current flow by monitoring the voltage drop across a shunt resistor or the magnetic fields generated by current flowing through a conductor. These high-voltage systems use current flow information to control and monitor power conversion, charging and discharging.

Hall-effect and shunt-based current sensors are among the most common technologies requiring current sensing. However, to date, using Hall-effect sensors in high-voltage applications has been problematic. In this article, I’ll go over the considerations when selecting each topology and highlight recent innovations that make it possible to use Hall-effect current sensors in high-voltage applications to simplify current sensing.

Shunt-based vs. Hall-effect-based current sensing

Shunt-based current sensors are generally more accurate than Hall-effect current sensors across the entire current range. Using stable amplifier technologies or precision analog-to-digital converters (ADCs) and precision shunt resistors, engineers can achieve high accuracy with less than 1% drift over the entire current measurement range, temperature and lifetime. Shunt-based sensors are popular in automotive traction inverters, servo drives and EV charging infrastructure applications.

Amplifiers and precision ADCs generally monitor for a voltage drop across a shunt resistor and provide a proportional output. Each current-sensing solution has different capabilities regarding operational voltages, offset, drift, bandwidth and ease of use. There are a few limiting factors with shunt-based systems – they will generally have a slower propagation delay because of the device’s architecture, and there is added design complexity, such as high- and low-side power. Shunt-based devices also require you to carefully consider shunt resistor parameters and power dissipation.

On the other hand, in-package Hall-effect current sensors are generally more cost-effective than shunt-based solutions, have a faster propagation delay, and are much simpler to design into a system. With in-package solutions, current flows through the package on the leadframe, removing the need for precision resistors and reducing cost and bill of materials. Additionally, there is no need for high- and low-side power supplies; you can use one low-side power supply to power a Hall-effect current, further reducing design complexity.

Simplifying high-voltage current sensing with Hall-effect sensor innovations

Despite the benefits delivered by Hall-effect current sensors, most designers have overlooked these devices for high-voltage systems given their high drift across temperature and lifetime. Hall-effect current sensors can drift significantly over their lifetime because of electronic and isolation decay.

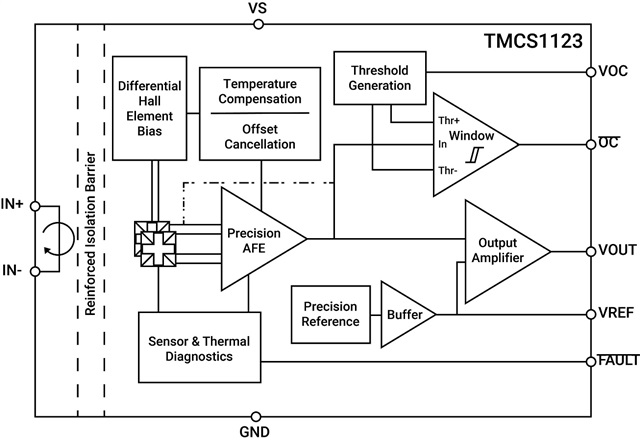

To address these drawbacks, my colleagues have worked on a solution to significantly reduce the lifetime sensitivity drift error of the TMCS1123 Hall-effect current sensor to ±0.5%, enabling engineers to design high-voltage systems that require less calibration or maintenance throughout the life of the system. We also reduced the total maximum sensitivity error over lifetime and temperature to ±1.75%, which helps increase efficiency and reduces costly system calibration. In addition, the TMCS1123 has differential Hall-effect sensing, significantly reducing magnetic field interference or crosstalk, along with other features such as overcurrent detection, a precision voltage reference and a sensor alert. See Figure 1.

Figure 1 TMCS1123 block diagram

Figure 1 TMCS1123 block diagramThe TMCS1123 also addresses some of the other limitations common among Hall-effect sensors, such as leadframe resistance and silicon die thermal constraints that limit the amount of current the device can handle. The TMCS1123 enables 75 ARMS at 25°C and achieves a ±1.75% sensitivity error over temperature and lifetime without calibration, making it a highly accurate solution throughout the lifetime of the system.

Current-sensing design considerations

Let's review some of the primary considerations when selecting a current sensor for a system. First, accuracy is an important consideration and should be one of the first defined parameters to determine a feasible technology. Second, power ratings are essential for all of the technologies mentioned above; the system's voltage and current levels must be within the devices’ specified parameters to safely and effectively operate. Bandwidth and speed are necessary for actively controlling switching systems, such as isolated DC/DC converters in solar energy. Design complexity is another crucial factor – the Hall-effect current sensor is straightforward to use on all voltage levels within the device limits, as it doesn’t require additional power supplies or components.

Conclusion

The need for highly accurate current measurements in high-voltage systems such as EV chargers and solar inverters is continuously growing, and several design challenges exist in high-voltage applications that make systems more complex and costlier to design. With current-sensing devices such as the TMCS1123, you can now accurately sense current in high-voltage applications like EV chargers, while limiting design complexity and tackling design problems quickly and at the right price.