SSZTC73 september 2015 DRV8305 , TMS320F28027F

Traditionally seen as the high end of DC motor types, brushless DC motors (BLDCs) have typically been reserved for systems with high performance or efficiency requirements. But as motor-drive systems become more integrated and control solutions become more readily available, system designers are finding it simpler than ever to move forward with BLDC motor solutions in order to reap the performance and efficiency benefits. To support this trend, TI is providing quality development tools to help you rapidly get your BLDC motor spinning while minimizing development cost.

In an earlier post, I discussed the LaunchPad™ development kit plus BoosterPack approach that essentially takes a microcontroller (MCU) LaunchPad kit and adds a peripheral BoosterPack, allowing you to evaluate the MCU, peripheral and entire system.

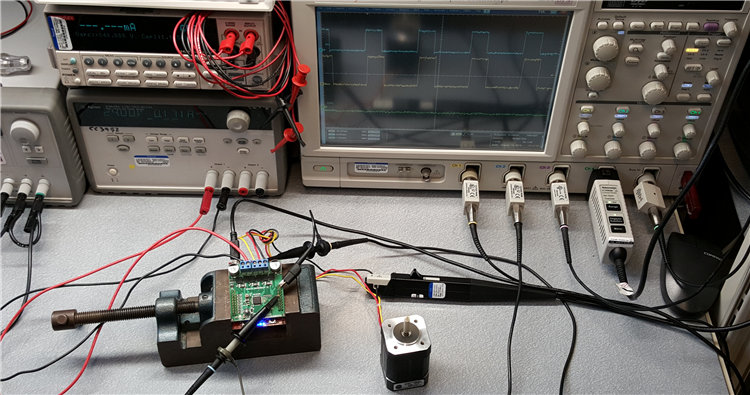

This combination can allow you to skip the costly and time-consuming steps of designing, laying out and debugging a test board for your motor system. The kit allows a motor system designer to connect the motor and immediately begin evaluating the motor, driver and controller performance. Figure 1 shows a standard three-phase BLDC motor connected directly to the kit. A 24V power supply provides both the power stage and controller power rails. The oscilloscope is looking at the input and output switching signals, compared against the motor current at 2kRPM. After initial evaluation, the LaunchPad and BoosterPack design files can be used as a reference for the final system design.

Figure 1 Example lab set-up to

evaluating a motor system

Figure 1 Example lab set-up to

evaluating a motor systemFor example, the LAUNCHXL-F28027F and BOOSTXL-DRV8301 work together for designing BLDC motor systems using (InstaSPIN-FOC™) sensorless field-oriented control technology. Expanding on the approach, the LAUNCHXL-F28069M allows for connecting two BoosterPacks and developing InstaSPIN-MOTION™ encoder-based sensored velocity and position field-oriented control in addition to sensorless InstaSPIN-FOC motor control. Now, we are releasing the BOOSTXL-DRV8305EVM (Figure 2) using our next-generation BLDC motor gate driver.

Figure 2 LAUNCHXL-F28027F +

BOOSTXL-DRV8305EVM

Figure 2 LAUNCHXL-F28027F +

BOOSTXL-DRV8305EVMIn addition to evaluation hardware, TI also provides comprehensive software and technical resources to minimize development overhead and time. MotorWare provides an extensive motor-control library, projects/labs/examples for each hardware kit, GUIs and technical documentation. The LaunchPad + BoosterPack combination allows engineers to begin software design immediately and progress throughout the hardware design phases.

I’d like to hear how you’re trying out these new resources for jump-starting your BLDC motor design. Let me know by logging in to post a comment below! Motor experts are also available 24/7, year-round on the TI E2E™ Community Motor Drive or InstaSPIN forums for device or technical questions.

Additional Resources:

- Visit www.ti.com/launchpad to learn more about how the TI LaunchPad and BoosterPack ecosystem is helping designers rapidly evaluate TI solutions.

- Read our application report describing the new gate drive architecture in the DRV8305.

- Order your own LaunchPad and BoosterPack evaluation kits in order to start your development today.