SSZTBV3 december 2015 TPS630250 , TPS63050

Almost every portable system needs a 3.3V rail. And for those systems powered by single-cell lithium batteries, there is always a question of how to make this rail. Stepping up the battery voltage (which typically varies from 3V to 4.2V) to 5V and then stepping the 5V down to 3.3V causes the power to go through double conversion. The efficiency of two power-conversion steps is the product of the efficiency of each of those steps, so the overall efficiency for the scenario I’ve described is low. For example, if the step-up converter is 90% efficient and the step-down converter is 95% efficient, the overall efficiency is just 85.5%. There must be a better way to generate the 3.3V that wastes less power.

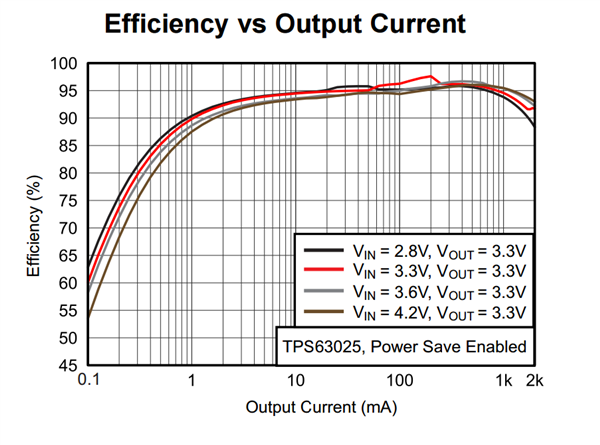

Using the TPS63025 buck-boost converter family provides higher efficiencies in these types of situations. By combining a >95% efficiency step-down converter and a >90% efficient step-up converter, the conversion efficiency is either >95% or >90% based on the battery voltage (see Figure 1). A buck-boost converter does not double-convert the power, but rather operates as a step-down or step-up converter as needed. Efficiency increases, which reduces temperature rise and increases the run time of the battery.

Figure 1 TPS63025 Efficiency vs. Output

Current

Figure 1 TPS63025 Efficiency vs. Output

CurrentYou can design such a buck-boost converter into almost any portable system. If you are designing a smartphone, a wafer chip-scale (WCSP) package provides the smallest solution size and is easily manufactured in high-density systems. But for industrial equipment such as barcode scanners, you’re not fighting for every square millimeter of printed circuit board (PCB). These types of applications can use a standard quad flat no-lead (QFN)-type package, which has solder fillets and can be visually inspected during manufacturing.

With the new buck-boost converters, the TPS630250 and the TPS63050 family of devices, engineers now have their choice of packages. For the absolute smallest size, the YFF package (WCSP) is preferable, while for less demanding manufacturing requirements, the RNC package (QFN) is available. Either way, these devices provide a 3.3V rail from a single-cell lithium battery with over 90% efficiency – giving engineers more choices and more applications.

What Applications Do You Have Which Should You Not Use a WCSP Package?