SSZTAH9 january 2017 LM5109B

Just like every MOSFET needs a gate driver to switch it, there’s always a driving force behind each motor. Depending on the complexity level and the system’s cost, size and performance requirements, there are different ways to drive motors.

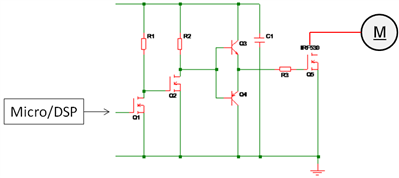

The most simple and discrete solution is a totem-pole/push-pull circuit consisting of two transistors. These transistors, which can be different combinations of NPN and PNP transistors, create an amplifier that converts the input logic signal to a high current signal, which in turn switches the MOSFETs and IGBTs on and off. In Figure 1, the emitters are connected to give an amplified output to drive the FET. This kind of solution has been widely used in many different applications including motor drives, mainly due to its low cost and ease of use, but there are still some limitations and drawbacks.

Figure 1 A Typical Push-pull/totem Pole

Gate Drive Circuit

Figure 1 A Typical Push-pull/totem Pole

Gate Drive CircuitFor example, the transistors can generate heat, which causes a thermal issue in some systems. Or both transistors can turn on for a short amount of time, which causes circuit shoot-through. For applications with limited PCB space, a totem-pole circuit is not an ideal choice either, as it requires multiple components to realize the gate drive function. For higher output voltages, the solution shown in Figure 1 will require additional level-shift circuitry to achieve the voltage level on the output – and on the input as well, when using a controller that only supplies 5V or less to drive the switch. The transistors and level-shift circuitry increase the bill of materials (BOM) count and required printed circuit board (PCB) space for totem-pole circuit solutions.

A gate-driver integrated circuit (IC) can resolve these issues. Gate-driver ICs implement the same functions as a totem-pole circuit but have many extra benefits:

- A gate-driver IC saves space and resources because it integrates all of the components into a single package. Thus, the physical size is smaller, the design is more straightforward and assembly is easier.

- A gate-driver IC simplifies board layout and reduces design uncertainty, as the data sheet has all of the specifications.

- The drive current is not limited to input base current and gain, so the drive capability is stronger, thus reducing switching losses and increasing efficiency.

- Protection features like under voltage-lockout (UVLO) and “anti-shoot-through” increase system robustness.

Although the totem-pole circuit is a mature solution that has been popular for many years, modern and future systems require higher integration and higher performance. With advances in semiconductor technology, the cost of gate-driver ICs is already comparable to discrete circuits, which makes the IC solution even more attractive and feasible for most applications.

TI offers a broad gate-driver portfolio that can fit in almost all markets and applications. TI’s gate drivers support voltages up to 620V for non-isolated solutions and 5kV for isolated solutions. The LM5109B is a popular solution for motor solutions below 100V. For more details, see the TI gate driver page.

If you prefer an even more integrated solution, there are system-level solutions available that offer not only gate-driving capability but also have MOSFETs, on-chip communication, and different levels of protection and control, all integrated into one chip. These solutions further reduce physical size and design uncertainty. TI’s DRV8xxx series, for example, is a popular solution for brushed-DC, brushless-DC and stepper motors. For more information, see the TI motor driver page.

All options have their pros and cons, and you need to choose the one that’s the best for your system. Start your design with the various solutions provided by TI and you will find the right one.

Additional Resources

- Check out these motor drive reference designs:

- Download the white paper, “Power electronics in motor drives: Where is it?”