SSZT178 april 2021 ADS131M02 , INA188 , OPA188 , REF70

Test and measurement applications like battery test, electrochemical impedance spectroscopy and semiconductor test require accurate current- and voltage-output DC power supplies. The current and voltage control accuracy of the equipment need to be better than ±0.02% of the full-scale range over a ±5°C ambient temperature change. The accuracy largely depends on temperature drift of the current-sense resistor and amplifiers. In this article, you will learn how different components affect system accuracy, and how to choose suitable components for a precision DC power-supply design.

The Output Driver

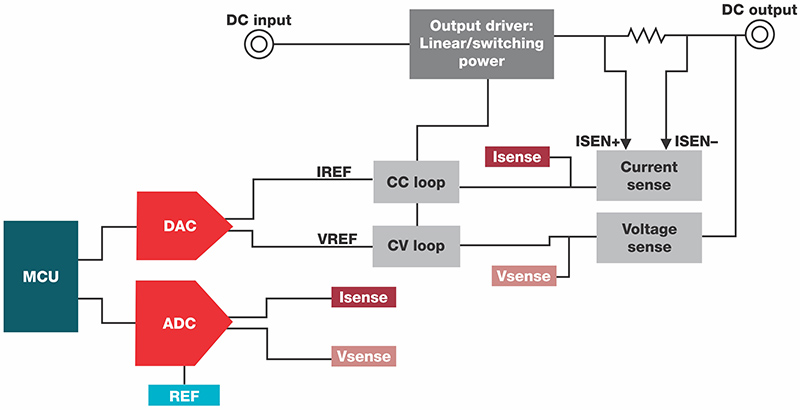

Figure 1 is a block diagram of a power supply, including an output driver, current- and voltage-sensing circuits, control loops, an analog-to-digital converter (ADC) and a digital-to-analog converter (DAC). The selection of an output driver depends on output accuracy, noise and power level. A linear power is used as an output driver for low-power (<5 W) or low-noise applications. A power operational amplifier (op amp) with integrated thermal and overcurrent protection is suitable for low-power applications.

Figure 1 Typical Block Diagram of a DC

Source

Figure 1 Typical Block Diagram of a DC

SourceUsing a linear output driver for higher output power is challenging because of power dissipation, however, so you’ll need a synchronous buck converter for higher output power, which can achieve 0.01% of full-scale range accuracy by keeping big filters at the output. For example, a 5-V output range can achieve 500-µV accuracy using a buck converter. You’ll also need to confirm that there are no pulse-skip and diode emulation modes in the converter, which increase output ripple at light loads. The C2000™ real-time microcontroller (MCU) is a good fit for precision synchronous buck converter power supplies because you can disable features you don’t want in the software.

Current and Voltage Sensing

A high-precision current shunt resistor and a low-drift instrumentation amplifier can measure the output current. The instrumentation amplifier’s input offset error and gain error are not a concern, as both errors are accounted for during system calibration. The instrumentation amplifier’s offset and gain drift, output noise, and gain nonlinearity are difficult to calibrate, however, and you should consider these errors when selecting a current-sense amplifier.

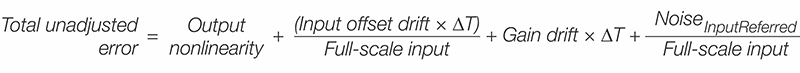

Equation 1 calculates the total unadjusted error of the current-sense amplifiers shown in Figure 2. The error from the common-noise rejection ratio is relatively small, and you can ignore it.

The INA188 has the least error among the amplifiers listed in the table. The error calculations use a ±5°C temperature variation, with 100-mΩ and 1-mΩ current resistors chosen for 1-A and 25-A outputs, respectively.

Figure 2 Total Unadjusted Error of

Current-sensing Amplifiers

Figure 2 Total Unadjusted Error of

Current-sensing AmplifiersUsing a differential or instrumentation amplifier enables you to monitor the load voltage very accurately. The amplifier senses both loads’ output voltage and ground to eliminate error from any voltage drop in the cables. System calibration adjusts the offset and gain errors of the amplifier, leaving only input offset drift. You can calculate the drift in parts per million by dividing the offset drift by the full-scale voltage. For example, with a 2.5-V full-scale range and 1-µV/°C offset drift, the drift will be 0.4 ppm/°C. If you need a lower-output voltage drift, you can choose a zero-drift op amp such as the OPA188, which has a maximum input offset drift of 85 nV/°C. However, 1-µV/°C offset drift precision op amps are sufficient for most applications.

The ADC

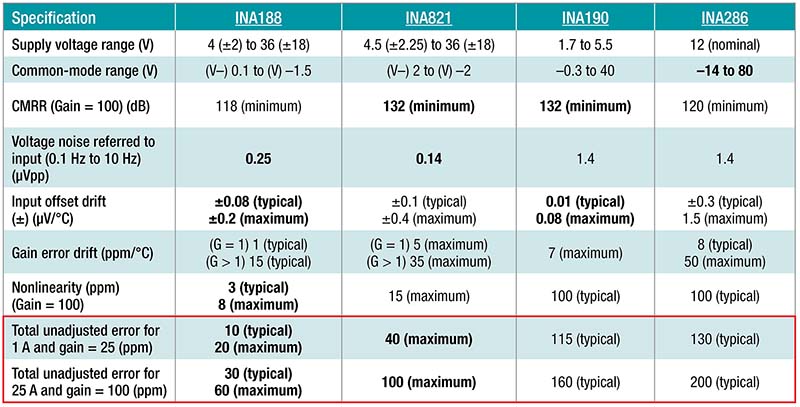

ADC offset and gain errors are adjusted during system calibration. Errors caused by drift and nonlinearity of the ADC are difficult to calibrate. Figure 3 compares errors of three different high-precision delta-sigma ADCs for a temperature variation ±5°C. The ADS131M02 has the least error among the ADCs listed in the table. The error calculation excludes the output noise of the ADC and the voltage reference error.

Figure 3 Total Unadjusted Error of

ADC

Figure 3 Total Unadjusted Error of

ADCYou can reduce error from noise significantly by increasing the oversampling ratio of the ADC. A low-noise (<0.23 ppmp-p) and low-drift voltage reference (<2ppm/°C) such as the REF70 is sufficient for DC power supply applications. The device has only 28 ppm of long-term drift for 0 to 1,000 hours of operation. The subsequent drift will be significantly lower than 28 ppm for the next 1,000 hours.

Control Loops

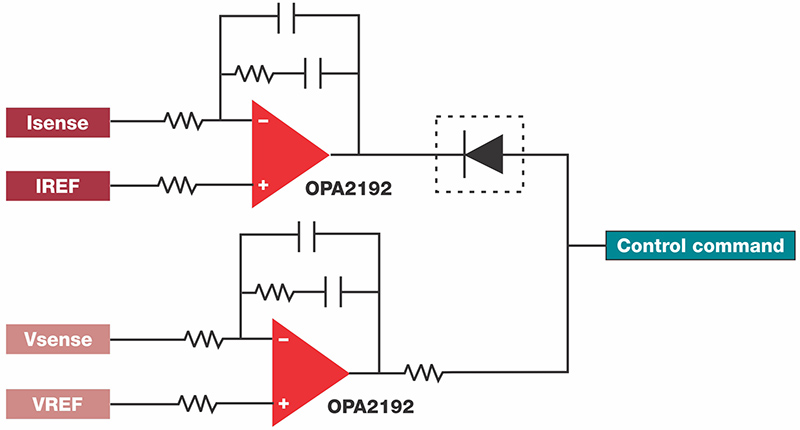

Figure 4 shows an analog control loop for the power supply. Even if you don’t need a constant-current output, keeping the constant-current loop will help with short-circuit protection. The constant-current loop will limit the output current by reducing the output voltage, and the current limit is programmable through the IREF setting.

Using a diode in between the constant-current and constant-voltage loops helps with constant voltage-to-constant current transition, or vice versa. A multiplexer-friendly op amp is suitable for constant-current and constant-voltage loops to avoid a short between amplifier inputs in open-loop operation. When any control loop is in an open-loop condition, the operational amplifier may see a differential voltage at its input pins greater than 0.7 V. A nonmultiplexer-friendly op amp has antiparallel diodes at the input pins, which doesn’t allow the differential voltage to exceed the diode drop. Therefore, a nonmultiplexer-friendly op amp increases the bias current of the amplifier, which may cause self-heating of the device and system inaccuracies as that current interacts with source impedances.

Figure 4 Constant-current and

Constant-voltage Loop Schematic

Figure 4 Constant-current and

Constant-voltage Loop SchematicYou can also implement control loops in digital domain inside C2000 real-time MCUs. High-resolution pulse-width modulation, a precision ADC and other analog peripherals of the C2000 real-time MCU help reduce the total number of components and bill of materials. The C2000 real-time MCU portfolio includes both 16- and 12-bit ADC options.

Conclusion

Consider temperature drift and noise specifications while designing a DC power supply for test and measurement applications. You can achieve less than 0.01% accuracy if you choose a low-drift amplifier and ADC products.

Additional Resources

- Check out the Precision Amplifiers Battery Test Systems video series.

- The Digitally Controlled Non-Isolated DC/DC Buck Converter Reference Design provides an example of buck converter implementation.

- Read the technical article, “How to Design One Battery Tester for a Wide Range of Sizes, Voltages and Form Factors” to understand the benefits of digital control loops.

- For test data, see the Battery Tester Reference Design for High Current Applications.