SLYA056 December 2021 DRV5011 , DRV5012 , DRV5013 , DRV5015 , DRV5021 , DRV5023 , DRV5032 , DRV5033 , TMAG5123 , TMAG5124 , TMAG5231

1 Two-State Selector Using Hall-Effect Sensors

Two state switches in the form of push-buttons, switches, and levers can be found in several applications, such as a cordless power tool, seat buckle, or even a smoke detector. While the applications that they are found in are ubiquitous and often unrelated, the operating principle is always basically the same. You have a system with binary states that you want to monitor. For example, the monitored object is either plugged in or not; the switch is either on or off; lastly the button is either toggled one way or not. All states or positions in between are expected to be brief, transitory, and do not need to be precisely monitored. Only the spatial bounds of the switch path are monitored.

There are many technologies and implementations of a switch, and each of those different technologies has key benefits or drawbacks that impact system behavior. Using Hall sensors as switches provides a highly reliable and cost-effective methodology with a large amount of flexibility for size, performance, and mechanical arrangements. Since Hall sensors are a true contactless switch mechanism, they are subject to lower mechanical or frictional wear, and are also immune to dust or other contaminants that could render a mechanical, optical, or other switch mechanisms inoperable.

Designing with a Hall-Effect Sensor

The first step for any given design is to choose the implementation. How the switch is implemented will likely depend upon the desired aesthetics, ergonomics, and the space constraints of your system enclosure. Figure 1-1 shows four possible structural implementations of a two-state selector. On the left is a toggle or lever switch similar to what you might see with a light switch. Second to the left is a slider switch. Second to the right is a push-button switch. On the right is a dial switch. It can be noted that each of these could be spring loaded such that one state is transitory while the other possible state is the default. Such spring behavior might be something more common to push buttons.

Figure 1-1 Mechanical Implementation

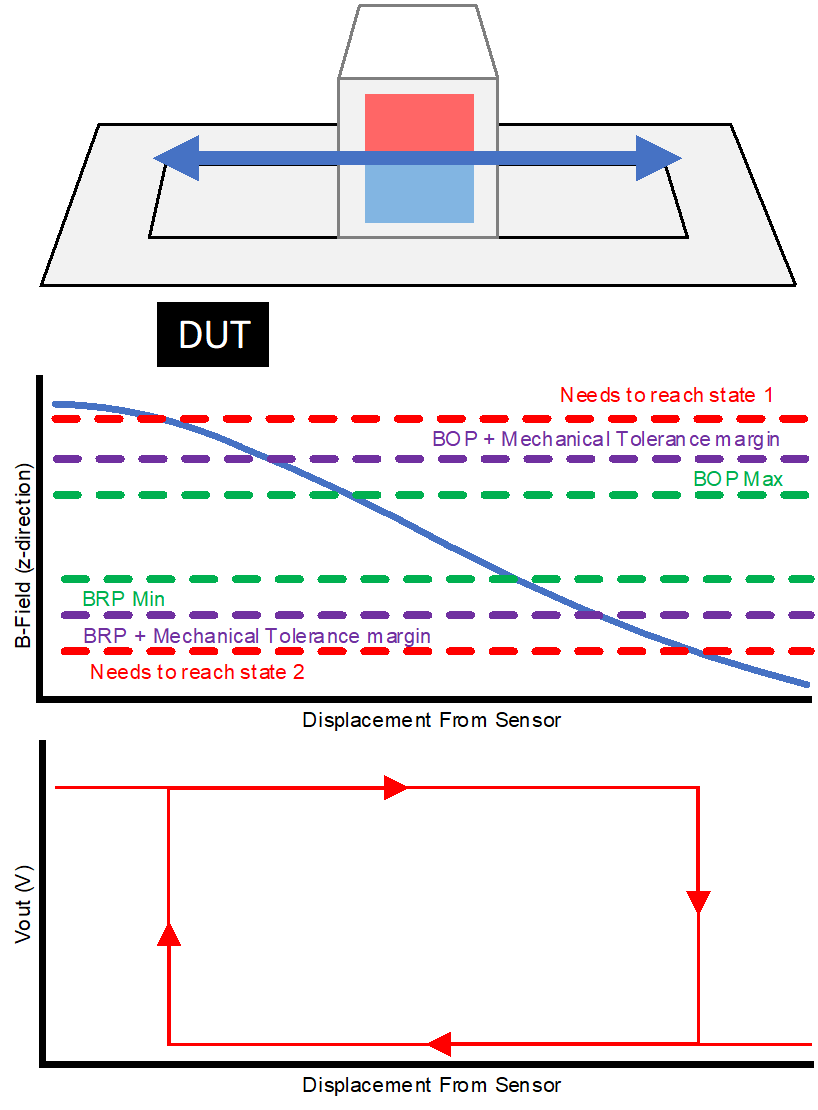

Figure 1-1 Mechanical ImplementationAside from the mechanical aspect of implementation, there is also the magnetic aspect of implementation. Depending on the movement and placement of your magnet, you might be able to use either a Hall-effect switch or a latch. In Figure 1-2, we have two different magnetic implementations with the sensor monitoring the field in the z direction or normal to the xy plane. In the first example, the B-field characteristic is good for a latch as the polarity seen by the sensor reverses once the slider crosses the midpoint of its travel path and the field strength is strong for both polarities.

As for the second example the magnet and sensor are oriented such that the device sees a strong field for one polarity and aside from the momentary switch in polarity, the field decreases as the slider moves away. Such a field characteristic is more suitable for a Hall-effect switch.

After deciding the implementation, you can begin the process of choosing the most suitable magnet and Hall-effect sensor combination. The magnet you use will depend upon the space constraints of where you can put it, its field strength, and its cost. For comparing how suitable various magnets are for your design, you will need to calculate their respective B-fields. Typically, there is a correlation between bigger magnets having a stronger field as well as a higher cost. Upon selecting a magnet, you can then select a Hall-effect switch or latch that is suitable for the magnet’s B-field characteristic over your two-state switch’s desired range of motion. According to the sensor’s location and sensing plane, the B-field from the magnet must cross both BRP, min and BOP, max along the magnet’s path of motion. This guarantees that design will always work regardless of DUT variation. However, some margin should be added in to also guarantee that your switch works regardless of system variation involving mechanical placement.

Figure 1-3 Design Bounds

Figure 1-3 Design BoundsDesign Challenges

One key challenge with the two-state selector is space. Typically, a two-state selector will have less range of motion or smaller implementation area than what might be found in a similar transition detection application involving hinges. To further add to this challenge, structural materials used in the switch module may influence the field of your magnet. For instance, if you use a spring in your switch, you will likely need to account for that in your B-field calculations.

Many springs are made of materials that are not magnetically inert. This can either help or hurt your design by diverting field from the sensor, or alternatively concentrating field toward the sensor. By being aware of this, you also can potentially exploit the material properties to concentrate the magnetic field in your favor or shield your device from unwanted fields.

The top left diagram in Figure 1-4 shows how the magnetic field lines concentrate in a surrounding mu-metal cylinder, thereby dramatically reducing the field seen by the sensor when compared to the unshielded sensor in the right-side diagrams.

Determining the B-field behavior for a given magnet sensor placement can by daunting if done by hand. However, there are various simulation packages and calculators available to do the calculations for you. In that regard, TI has our own Magnetic Proximity Calculator which provides you the means of rapidly adjusting various relevant variables to find the design that is just right for you.

For more details and guides related to using Hall-effect sensors for transition detection, see Table 1-1 and Table 1-2.

| Device | Characteristics | Design Considerations |

|---|---|---|

| DRV5032 | Ultra-low-power digital switch Hall-effect sensor available in SOT-23, X2SON, and TO-92 packages. Both omnipolar and unipolar options available. | Great for low power applications. This device can operate on as little as 1.65 V with typical current consumption below a 1μA. DU and FD are dual unipolar variants that are active low for North and South oriented fields. |

| TMAG5231 | Ultra-low-power digital switch Hall-effect sensor available in SOT-23. | Great for low power applications. This device can operate on as little as 1.65 V with typical current consumption below a 1μA. |

| TMAG5123 | Omnipolar, in-Plane, high-precision, high-voltage, Hall-Effect switch available in SOT-23 package. | Unlike most switch devices on the market that sense in the z-direction, this device is a lateral sensor that detects magnetic fields parallel to the surface of the package. |

| DRV5033 | Omnipolar, wide voltage, 30Khz Bandwidth Hall-effect Switch available in SOT-23 and TO-92 packages | This device is more suitable for designs in which quick response time is the key concern. |

| DRV5012 | Ultra-low-power Hall-effect latch available in X2SON. | Great for low power applications. This device can operate on as little as 1.65 V with typical current consumption below a 2μA. |

| Name | Description |

|---|---|

| HALL-ADAPTER-EVM | Provides a fast, easy, and inexpensive way to interface with Hall-effect switch ICs. |

| Magnetic Sensing Proximity Tool | A tool that can be used to help determine a possible magnet sensor design. |

| TI Precision Labs - Magnetic Sensors | A helpful video series describing the Hall-Effect and how it is used in various applications. |

| Transition Detection Using Hall-effect Sensors | An application report on a similar generic Hall-effect switch application. |