SLVS515D December 2004 – November 2015 TLC5940

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Parameter Measurement Information

- 8 Detailed Description

- 9 Application and Implementation

- 10Power Supply Recommendations

- 11Layout

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

封装选项

机械数据 (封装 | 引脚)

散热焊盘机械数据 (封装 | 引脚)

订购信息

9 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

9.1 Application Information

The device is a 16-channel, constant sink current, LED driver. This device can be connected in series to drive many LED lamps with only a few controller ports. Output current control data, dot correction data and PWM control data can be written from the SIN input terminal.

9.2 Typical Application

Figure 22. Cascading Devices

Figure 22. Cascading Devices

9.2.1 Design Requirements

For this design example, use the input parameters shown in Table 4.

Table 4. Design Parameters

| PARAMETERS | VALUES |

|---|---|

| VCC input voltage range | 3.0 V to 5.5 V |

| LED lamp (VLED) input voltage range | >Maximum LED forward voltage (VF) + IC knee voltage |

| SIN, SCLK, XLAT, GSCLK, and BLANK voltage range | Low level = GND, High level = VCC |

9.2.2 Detailed Design Procedure

9.2.2.1 Serial Data Transfer Rate

Figure 22 shows a cascading connection of n TLC5940 devices connected to a controller, building a basic module of an LED display system. The maximum number of cascading TLC5940 devices depends on the application system and is in the range of 40 devices. Equation 9 calculates the minimum frequency needed:

where

- f(GSCLK): minimum frequency needed for GSCLK

- f(SCLK): minimum frequency needed for SCLK and SIN

- f(update): update rate of whole cascading system

- n: number cascaded of TLC5940 device

9.2.2.2 Grayscale (GS) Data

There are a total of 16 sets of 12-bit GS data for the PWM control of each output. Select the GS data of each LED lamp and write the GS data to the register following the signal timing.

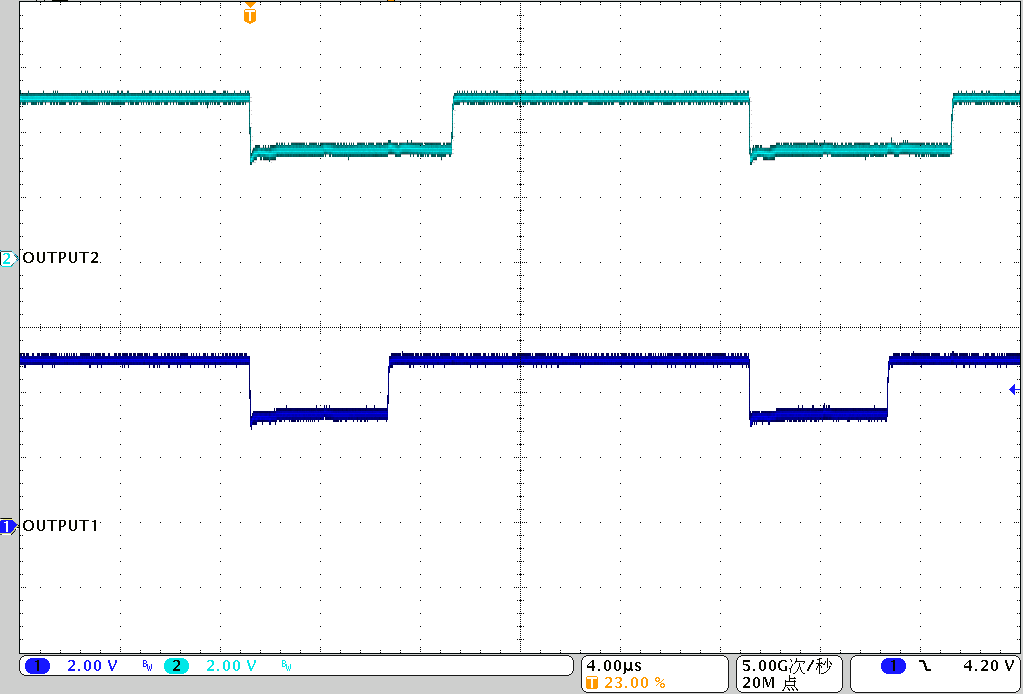

9.2.3 Application Curve

Figure 23. Output Waveform with Different Grayscale PWM Data

Figure 23. Output Waveform with Different Grayscale PWM Data