SNVS692G January 2011 – October 2015 LMZ14203H

PRODUCTION DATA.

- 1 Features

- 2 Applications

- 3 Description

- 4 Revision History

- 5 Pin Configuration and Functions

- 6 Specifications

- 7 Detailed Description

-

8 Application and Implementation

- 8.1 Application Information

- 8.2

Typical Application

- 8.2.1 Design Requirements

- 8.2.2

Detailed Design Procedure

- 8.2.2.1 Design Steps for the LMZ14203H Application

- 8.2.3 Application Curve

- 9 Power Supply Recommendations

- 10Layout

- 11Device and Documentation Support

- 12Mechanical, Packaging, and Orderable Information

10 Layout

10.1 Layout Guidelines

PCB layout is an important part of DC-DC converter design. Poor board layout can disrupt the performance of a DC-DC converter and surrounding circuitry by contributing to EMI, ground bounce and resistive voltage drop in the traces. These can send erroneous signals to the DC-DC converter resulting in poor regulation or instability. Good layout can be implemented by following a few simple design rules.

- Minimize area of switched current loops.

- Have a single point ground.

- Minimize trace length to the FB pin.

- Make input and output bus connections as wide as possible.

- Provide adequate device heat-sinking.

From an EMI reduction standpoint, it is imperative to minimize the high di/dt paths during PCB layout. The high current loops that do not overlap have high di/dt content that will cause observable high frequency noise on the output pin if the input capacitor (Cin1) is placed at a distance away from the LMZ14203. Therefore place CIN1 as close as possible to the LMZ14203 VIN and GND exposed pad. This will minimize the high di/dt area and reduce radiated EMI. Additionally, grounding for both the input and output capacitor should consist of a localized top side plane that connects to the GND exposed pad (EP).

The ground connections for the feedback, soft-start, and enable components should be routed to the GND pin of the device. This prevents any switched or load currents from flowing in the analog ground traces. If not properly handled, poor grounding can result in degraded load regulation or erratic output voltage ripple behavior. Provide the single point ground connection from pin 4 to EP.

Both feedback resistors, RFBT and RFBB, and the feed forward capacitor CFF, should be close to the FB pin. Since the FB node is high impedance, maintain the copper area as small as possible. The trace are from RFBT, RFBB, and CFF should be routed away from the body of the LMZ14203 to minimize noise.

This reduces any voltage drops on the input or output of the converter and maximizes efficiency. To optimize voltage accuracy at the load, ensure that a separate feedback voltage sense trace is made to the load. Doing so will correct for voltage drops and provide optimum output accuracy.

Use an array of heat-sinking vias to connect the exposed pad to the ground plane on the bottom PCB layer. If the PCB has a plurality of copper layers, these thermal vias can also be employed to make connection to inner layer heat-spreading ground planes. For best results use a 6 × 6 via array with minimum via diameter of 8 mils thermal vias spaced 59 mils (1.5 mm). Ensure enough copper area is used for heat-sinking to keep the junction temperature below 125°C.

10.1.1 Power Module SMT Guidelines

The recommendations below are for a standard module surface mount assembly

- Land Pattern – Follow the PCB land pattern with either soldermask defined or non-soldermask defined pads

- Stencil Aperture

- For the exposed die attach pad (DAP), adjust the stencil for approximately 80% coverage of the PCB land pattern

- For all other I/O pads use a 1:1 ratio between the aperture and the land pattern recommendation

- Solder Paste – Use a standard SAC Alloy such as SAC 305, type 3 or higher

- Stencil Thickness – 0.125 mm to 0.15 mm

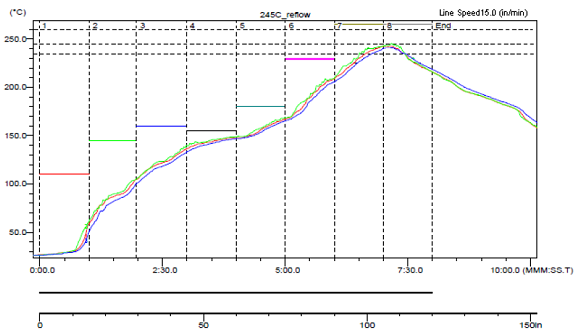

- Reflow - Refer to solder paste supplier recommendation and optimized per board size and density

- Refer to AN Design Summary LMZ1xxx and LMZ2xxx Power Modules Family (SNAA214) for Reflow information.

- Maximum number of reflows allowed is one

Figure 48. Sample Reflow Profile

Figure 48. Sample Reflow Profile

Table 1. Sample Reflow Profile Table

| PROBE | MAX TEMP (°C) | REACHED MAX TEMP | TIME ABOVE 235°C | REACHED 235°C | TIME ABOVE 245°C | REACHED 245°C | TIME ABOVE 260°C | REACHED 260°C |

|---|---|---|---|---|---|---|---|---|

| 1 | 242.5 | 6.58 | 0.49 | 6.39 | 0 | – | 0 | – |

| 2 | 242.5 | 7.1 | 0.55 | 6.31 | 0 | 7.1 | 0 | – |

| 3 | 241 | 7.09 | 0.42 | 6.44 | 0 | – | 0 | – |

10.2 Layout Example

Figure 49. Minimize Area of Current Loops in Buck Module

Figure 49. Minimize Area of Current Loops in Buck Module

Figure 50. PCB Layout Guide

Figure 50. PCB Layout Guide

10.3 Power Dissipation and Board Thermal Requirements

For a design case of VIN = 24 V, VOUT = 12 V, IOUT = 3 A, TA (MAX) = 65°C , and TJUNCTION = 125°C, the device must see a maximum junction-to-ambient thermal resistance of:

This RθJA-MAX will ensure that the junction temperature of the regulator does not exceed TJ-MAX in the particular application ambient temperature.

To calculate the required RθJA-MAX we need to get an estimate for the power losses in the IC. The following graph is taken form the Typical Characteristics section (Figure 16) and shows the power dissipation of the LMZ14203H for VOUT = 12 V at 85°C TA.

Figure 51. Power Dissipation VOUT = 12V TA = 85°C

Figure 51. Power Dissipation VOUT = 12V TA = 85°C

Using the 85°C TA power dissipation data as a conservative starting point, the power dissipation PD for VIN = 24 V and VOUT = 12V is estimated to be 3.5W. The necessary RθJA-MAX can now be calculated.

To achieve this thermal resistance the PCB is required to dissipate the heat effectively. The area of the PCB will have a direct effect on the overall junction-to-ambient thermal resistance. In order to estimate the necessary copper area we can refer to Figure 52. This graph is taken from the Typical Characteristics section (Figure 31) and shows how the RθJA varies with the PCB area.

Figure 52. Package Thermal Resistance RθJA 4-Layer PCB With 1-oz Copper

Figure 52. Package Thermal Resistance RθJA 4-Layer PCB With 1-oz Copper

For RθJA-MAX< 17.1°C/W and only natural convection (that is., no air flow), the PCB area will have to be at least 52 cm2. This corresponds to a square board with 7.25 cm x 7.25 cm (2.85 in x 2.85 in) copper area, 4 layers, and 1oz copper thickness. Higher copper thickness will further improve the overall thermal performance. As a reference, the evaluation board has 2-oz copper on the top and bottom layers, achieving RθJA of 14.9°C/W for the same board area. Note thermal vias should be placed under the IC package to easily transfer heat from the top layer of the PCB to the inner layers and the bottom layer.

For more guidelines and insight on PCB copper area, thermal vias placement, and general thermal design practices see the application note, AN-2020 Thermal Design By Insight, Not Hindsight (SNVA419).