ZHCSEQ8 March 2016 DRV10964

PRODUCTION DATA.

- 1 特性

- 2 应用范围

- 3 说明

- 4 修订历史记录

- 5 Pin Configuration and Functions

- 6 Specifications

-

7 Detailed Description

- 7.1 Overview

- 7.2 Functional Block Diagram

- 7.3 Feature Description

- 7.4 Device Functional Modes

- 8 Application and Implementation

- 9 Power Supply Recommendations

- 10Layout

- 11器件和文档支持

- 12机械、封装和可订购信息

8 Application and Implementation

NOTE

Information in the following applications sections is not part of the TI component specification, and TI does not warrant its accuracy or completeness. TI’s customers are responsible for determining suitability of components for their purposes. Customers should validate and test their design implementation to confirm system functionality.

8.1 Application Information

DRV10964 is used in sensorless three-phase BLDC motor control. The driver provides a high performance, high reliability, flexible and simple solution for compute fan applications. The following design shows a common application of the DRV10964.

8.2 Typical Application

Figure 16. Typical Application Schematic

Figure 16. Typical Application Schematic

8.2.1 Design Requirements

Table 3 lists several key motor characteristics and recommended ranges which the DRV10964 is capable of driving. However, that does not necessarily mean motors outside these boundaries cannot be driven by DRV10964.

Recommended ranges listed in Table 3 can serve as a general guideline to quickly decide whether DRV10964 is a good fit for an application. Motor performance is not ensured for all uses.

Table 3. Key Motor Characteristics and Recommended Ranges

| Rm (Ω) | Lm (µH) | Kt (mV/Hz) | fFG_max (Hz) | |

|---|---|---|---|---|

| Recommended Value | 2.5 ~ 10 | 50 ~ 1000 | 1 ~ 100 | 1300 |

Rm - Motor phase resistance between phase to phase;

Lm - Motor phase to phase inductance between phase to phase;

Kt - Motor BEMF constant from phase to center tape;

fFG_max - Maximum electrical frequency. Maximum motor speed can be calculated from:

- If FGS = 1, RPM = (fFG_max × 3 x 60)/ number of pole pairs

- If FGS = 0, RPM = (fFG_max × 120)/ number of pole pairs

8.2.2 Detailed Design Procedure

1. Refer to Design Requirements and make sure your system meets the recommended application range.

2. Refer to the DRV10964 Tuning Guide and measure the motor parameters.

3. Refer to the DRV10964 Tuning Guide. Configure the parameters using DRV10964 GUI, and optimize the motor operation. The Tuning Guide takes the user through all the configurations step by step, including: start-up operation, closed-loop operation, current control, initial positioning, lock detection, and anti-voltage surge.

4. Build your hardware based on Layout Guidelines.

5. Connect the device into system and validate your system solution

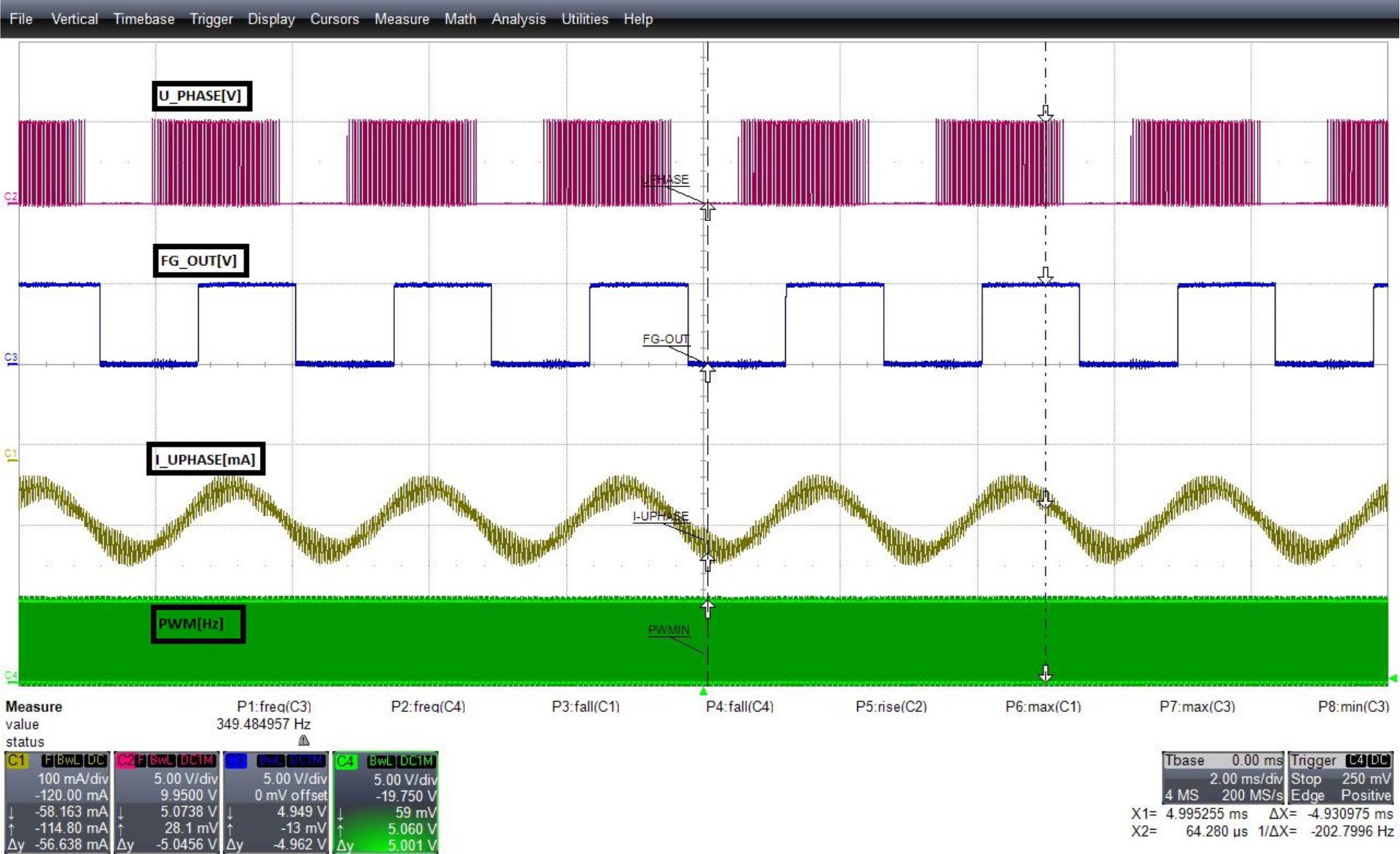

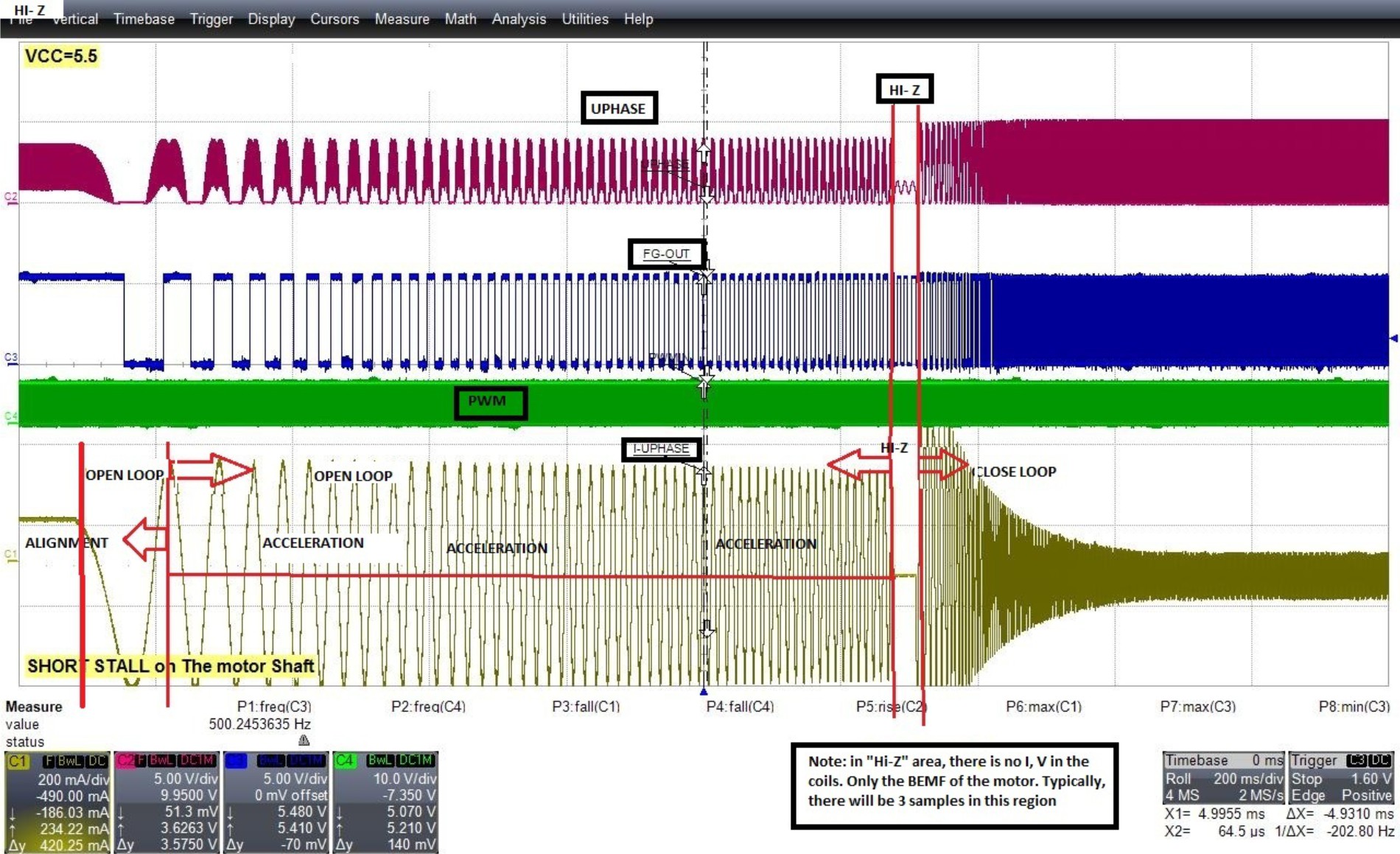

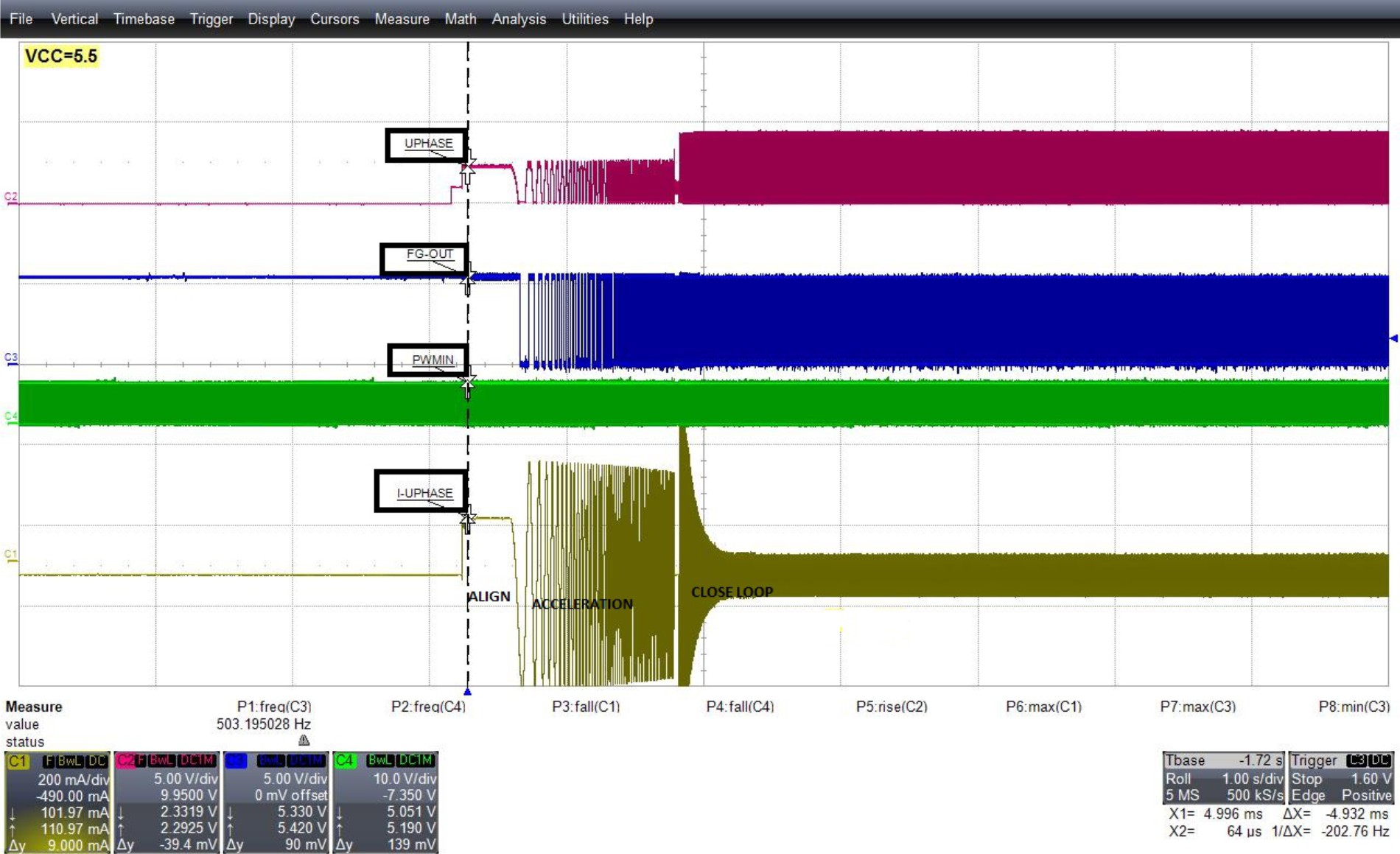

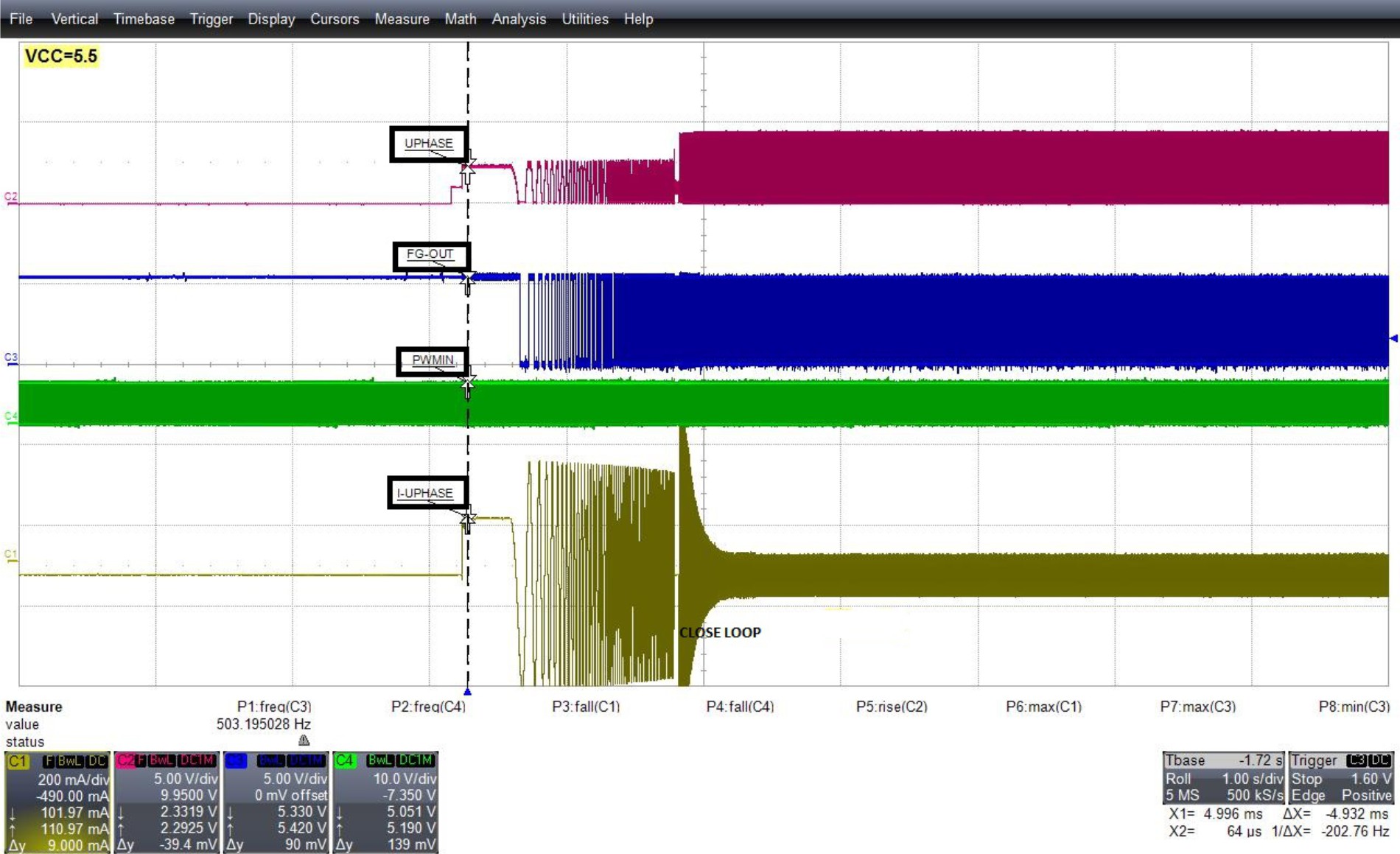

8.2.3 Application Curves