SSZTC29 october 2015 TUSB1002 , TUSB1042I , TUSB1046A-DCI , TUSB211 , TUSB212 , TUSB212-Q1 , TUSB213 , TUSB213-Q1 , TUSB214 , TUSB214-Q1 , TUSB215 , TUSB215-Q1 , TUSB501 , TUSB522P , TUSB542 , TUSB544 , TUSB546A-DCI , TUSB551 , TUSB564

As my family station wagon evolves into a home theater, I am going to need more USB ports. I’ll need at least two for front-seat passengers, but will also want back-seat passengers to be able to provide content (music, videos) in the head unit. Some cars today have USB charging ports in both the second and third rows for passengers to locally enjoy music and videos. However, in the future, I would like to be able to receive data from there also.

Accomplishing what I want proves very difficult, however. Today’s hubs redrive data signals over long distances, but they cannot do USB On-The-Go (OTG) or similar techniques that are required by popular smartphones. USB-compliant hub designers face major challenges as they try to work around this lack of functionality. Designers can use switches to flip the upstream port to the downstream port, yet this negatively impacts signal integrity.

This challenge has driven the need for a new bidirectional redriver. In real time, a bidirectional redriver must analyze the signal, determine the host and device side, determine the data direction, and compensate the signal lost. This capability requires both analog and digital technology.

As a user, I don’t want to find out that my attached device does not have enough receive sensitivity to accept a signal that comes from a short 3m cable. In fact, I want that signal to be able to go the distance between my family station wagon’s head unit and third row!

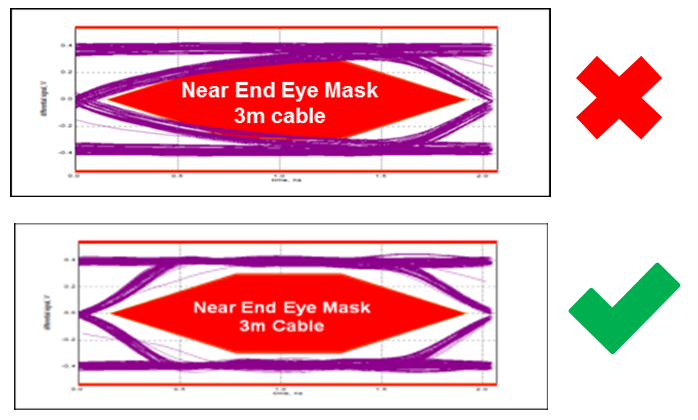

Figure 1 The TUSB211 Improves the

Raising Edge in a Near-side Eye Mask with a 3m Cable

Figure 1 The TUSB211 Improves the

Raising Edge in a Near-side Eye Mask with a 3m CableTo make that possible, my system will need a bidirectional USB 2.0 redriver. TI has introduced the first such redriver, TUSB211. It is compliant with all existing standards such as BC 1.2 and OTG, as well as legacy standards like USB 1.0 and 1.1. As shown in Figure 1, designers using a bidirectional redriver like the TUSB211 can see dramatic improvement in the near-side eye. The raising edge very clearly passes the eye diagram test now.

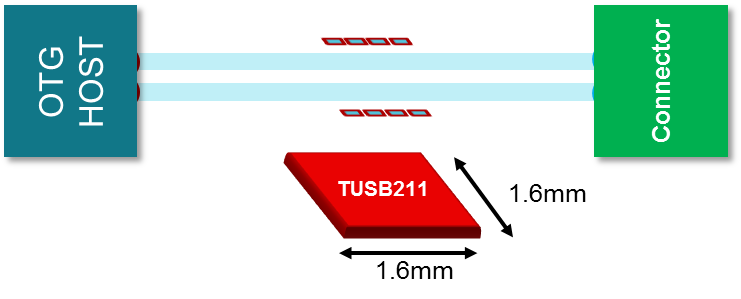

Having been involved with the USB interface for many years, I have seen that designers typically identify a need for a redriver after the first prototype builds if they experience an issue with signal integrity. The unique design of the TUSB211 makes it easy for you to add it after you identify the need, rather than being forced to decide earlier in the design process. You can design and lay out the board with landing pads for the TUSB211 and then wait for prototype test results before deciding whether to populate the redriver. Once you have test results and have decided that you want to add the redriver on the PCB, you simply mount it; there is no need to cut the traces. This is what we refer to as flow-through packaging, as shown in Figure 2.

Figure 2 The TUSB211 Is Designed onto a

Printed Circuit Board (PCB) without Populating the Device to Enable Easy

Modifications

Figure 2 The TUSB211 Is Designed onto a

Printed Circuit Board (PCB) without Populating the Device to Enable Easy

ModificationsI see this redriver greatly helping to achieve my desire for more high-speed data ports in my car. It can also be used in several other applications where people want to extend USB 2.0 to further distances, including home entertainment systems, industrial automation and more. In those applications, you can cascade this device to extend the reach of the cable even further.

Leave us a note below and let us know what application you are most excited to see benefit from a bidirectional redriver.

Additional Resources

- Read the TUSB211 data sheet.

- Learn more about TI’s USB signal-conditioning portfolio.

- Download the white paper, “Active USB cable for automotive applications.”