SSZTAX1 september 2016 SN74LVC1G07 , TLK105 , TMS320F28377D

We heard you and now we want to help you! We released our first DesignDRIVE industrial communication reference design (TIDM-DELFINO-ETHERCAT) to help ease your development of IEC 61158-compliant EtherCAT slave nodes based on our C2000™ real-time control microcontrollers (MCUs). Since C2000 MCU DesignDRIVE has the perspective of those developing for industrial real time control; we have seen the popularity worldwide for the support of EtherCAT. The demand appears to fall into two categories primarily: a) when required to interface to a larger/factory-wide EtherCAT network and b) when selected to replace CAN networks to fulfill higher bandwidth and lower latency node to node communication requirements in industrial machines.

There are some very good reasons why EtherCAT is a natural fit for C2000 MCUs in industrial automation applications. First, both have been designed for real time applications. Most EtherCAT slaves rely on hardware gates, versus a software approach, to handle the real-time data link layer thus enabling node-to-node packet latencies in the range of one microsecond. That latency makes EtherCAT one of the best protocols for addressing real-time communication needs. C2000 MCUs, have been built for real-time control. This is evident when you look at C2000 MCU features such as zero wait-state accesses to a 3.5 MSPS ADC with hardware post processing, 50ns PWM trip time from an overcurrent event and a 95ns floating point Park transform time. Both architectural philosophies reduce the CPU loading thus reducing the time/cycles needed to perform the main communications or control loops.

Next, both EtherCAT and C2000 MCUs place a premium on the importance of reducing overall system cost. That’s why the required memory to run an EtherCAT slave stack is kept to a minimum. Likewise, the C2000 MCUs, especially for industrial drives applications, integrate an unprecedented number of drive functions on-chip such as the absolute encoder master, sigma-delta filters, over-current comparators, current loop accelerator, high performance ADCs and DACs, clockwise-counter clock- wise (CW/CCW) inputs, pulse train output (PTO) and program storage. In addition, the mathematically enhanced C28x MCU instruction set has been optimized for real-time, computational code and results in memory-saving high-density code.

Because of the common philosophy placing priority on real-time capabilities and the benefits of using them together, C2000 MCUs and EtherCAT slaves are a natural fit and commonly found together in applications like high performance industrial servo motor control.

Why Did You Base the EtherCAT Reference on the ET1100?

The answer is quite simple. To us, the ET1100 ASIC from Beckhoff Automation GmbH, the inventor of EtherCAT, is the “gold standard” for compliance to the EtherCAT slave implementation and use model.

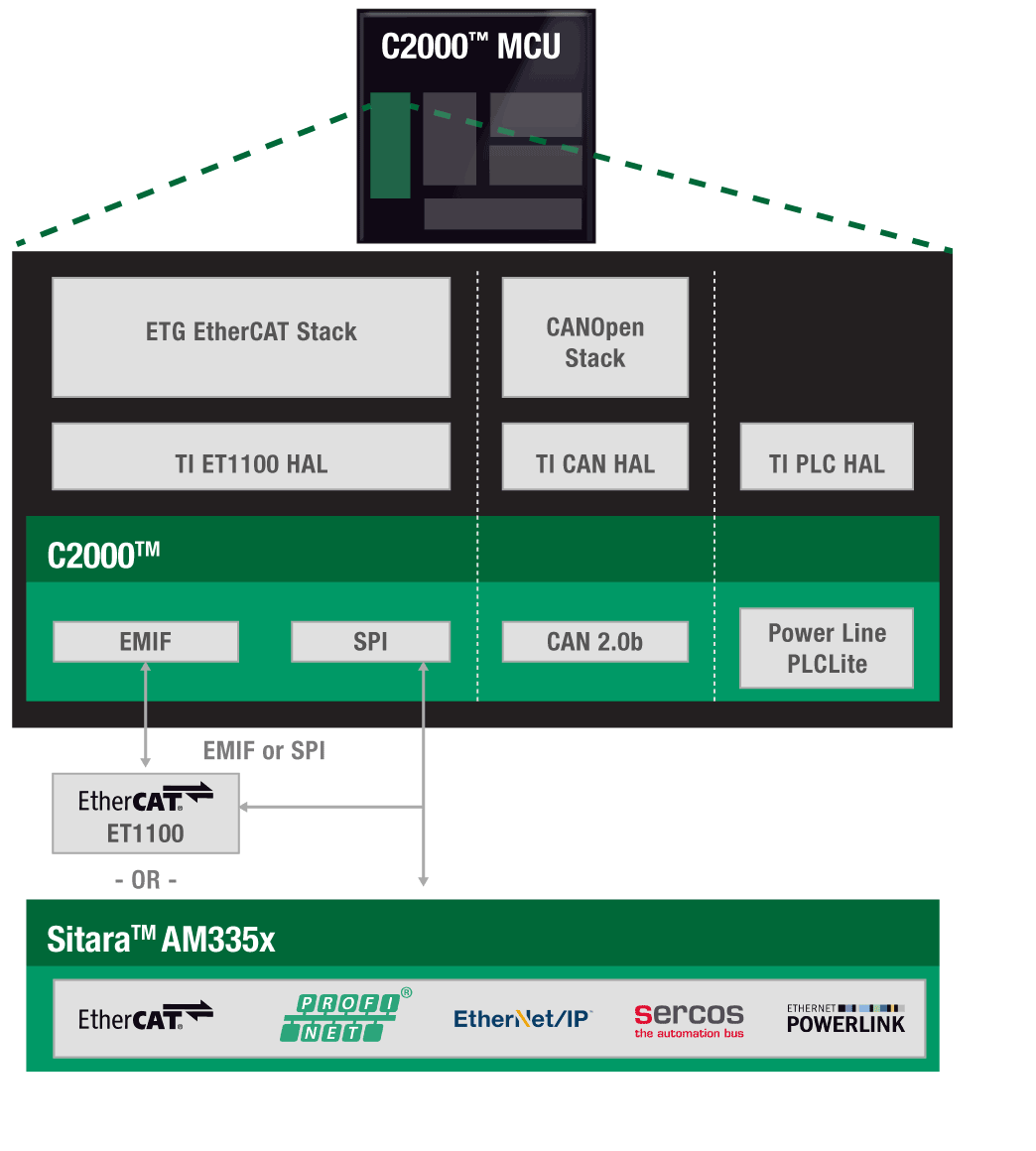

Whether a commercially available EtherCAT slave node is implemented in an FPGA or ASIC, the bases for most designs are derived directly from the Beckhoff or are built to behave compatibly to the Beckhoff design. We want our reference solutions to be held to this same standard and extend seemless compatibility to existing EtherCAT networks, even allowing the slave stack to leverage either 16 bit parallel or SPI interfaces on the ET1100 as is. The DesignDRIVE EtherCAT Slave software solution provided as part of the TIDesign reference design, as well as part of future DesignDRIVE EtherCAT releases, will always strive to be compatible with the gold standard.

Start developing your next design today. Visit the below links for more information:

- Download the TI Design now

- Read more about "Designing the next generation of industrial drive and control systems"

- Read more about industrial drive control with our blog series