SSZT949 september 2017 DRA710

Cars use communication protocols such as Controller Area Network (CAN), Local Interconnect Network (LIN), FlexRay, Media Oriented Systems Transport (MOST), and Ethernet to communicate between different electronic control units (ECUs). For example, a body control module (BCM) communicates with a rain sensor using LIN. Similarly, an onboard diagnostic scan tool communicates with the ECUs in a car using CAN or Ethernet.

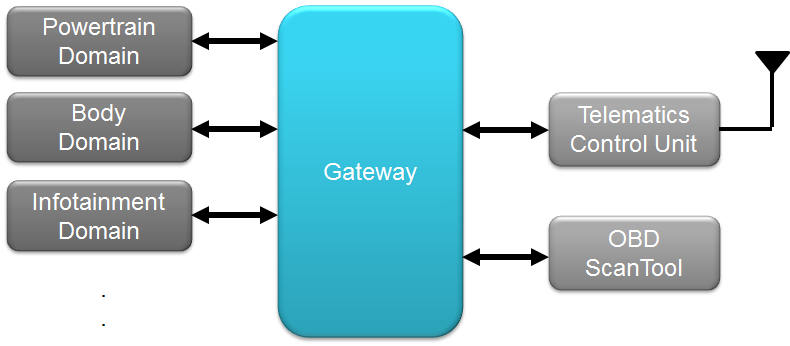

In order for these ECUs to communicate and exchange data, they need a way to bridge across different domains and protocols. That’s where gateways come in. As Figure 1 shows, gateways connect different ECUs, translating data from one protocol to another before forwarding it on to the intended recipient.

Figure 1 A Typical Vehicle Network

Configuration Showing the Gateway

Figure 1 A Typical Vehicle Network

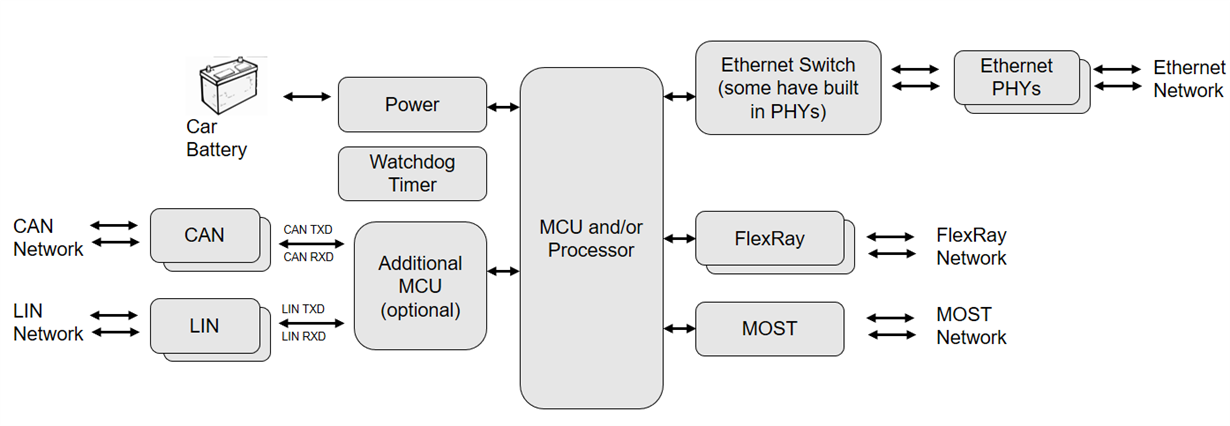

Configuration Showing the GatewayFigure 2 shows a typical block diagram of a gateway module. As you can see, a gateway is a collection of communication interface physical layers (PHYs), along with a processor and corresponding power-management devices.

Figure 2 Automotive Gateway Block

Diagram

Figure 2 Automotive Gateway Block

DiagramAs cars become more connected they require more data, which has led Ethernet to become more prevalent in cars; gateways evolved to meet this need. Whereas older gateways have smaller, simpler microcontrollers (MCUs) as their controllers, newer gateways use processors, sometimes with a supplementary MCU. The difference between a processor and MCU is the memory – processors have external memory, while MCUs store everything on-chip.

Why the shift to processors? Part of it is from a support standpoint. Many processors have Ethernet integrated, as well as the software to support it. Processors with more memory can run familiar operating systems such as Linux, which enable greater portability and cut down on development time. Additionally, some ECUs have gateway functionality integrated. By using a multicore processor from the Jacinto family, for example, you can divide the tasks for the ECU’s functionality from the gateway functionality. Divvying up the tasks gives each core a smaller load, allowing their clocks to run at a lower speed while still letting them meet the real-time requirements of a gateway.

Another reason for the shift from MCUs to processors is the amount of processing power needed to translate data between different communication domains. Ethernet is much faster than either CAN or LIN, with the single-twisted pair 100BASE-T1 leading the way into automotive Ethernet. Gateways must be able to keep up with 100Mbps and eventually gigabit speeds. Plus, some gateways may contain eight or more CAN ports and 10 to 12 Ethernet ports. Add to that the time-critical nature of communications and you’ll find you need a lot more processing power than an MCU can provide.

As I mentioned, many gateways have several ports for each protocol – more than a processor. While an external Ethernet switch may be able to take care of Ethernet, other protocols such as CAN and LIN will need another solution. A supplementary MCU can provide those ports for the gateway and forward the data to the processor, while still leveraging the computing power of a processor to translate and forward packets from one domain to another.

The automotive stand-alone gateway with Ethernet and CAN reference design provides a building block for Ethernet- and CAN-capable gateways. It features a JacintoTM DRA710 processor with two Ethernet ports (one 100BASE-TX protocol and one 100BASE-T1), two CAN ports, and an associated power tree.

Additional Resources

- Learn more about the Automotive Stand-alone Gateway with Ethernet and CAN Reference Design

- Learn more about Jacinto infotainment processors

- Learn more about Body Control Modules