SSZT282 july 2020 BQ21061 , BQ24040 , BQ2970 , BQ2971 , BQ2972 , BQ2973 , DRV10964 , MSP430FR2110 , MSP430FR2111 , TPS61023 , TPS7A02 , TPS7A03

Wearing an electric mask, also known as an E-mask or digital mask, can increase your comfort level compared to disposable or N95 masks. An electric mask is similar to a central ventilation system: a fan inside the mask allows users to inhale the outside air, which enters the mask after being filtered through a filter element. This design helps combat breathing difficulties that come from wearing masks for a long time. At the same time, its circulation ventilation function helps reduce the amount of fogging that occurs when wearing a pair of glasses with a mask.

Table 1 compares different types of masks.

| Mask type | Pros | Cons |

|---|---|---|

| Disposable medical mask |

|

|

| N95 mask |

|

|

| Electric mask |

|

|

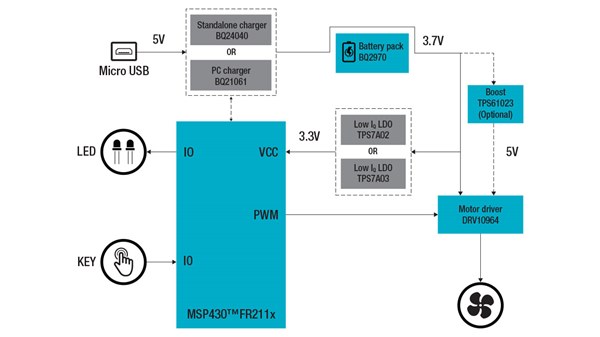

TI provides a complete set of solutions for designing electric masks. Figure 1 is a system diagram of common electric masks.

Figure 1 Electric mask system

diagram

Figure 1 Electric mask system

diagramLithium-ion battery-charging solution

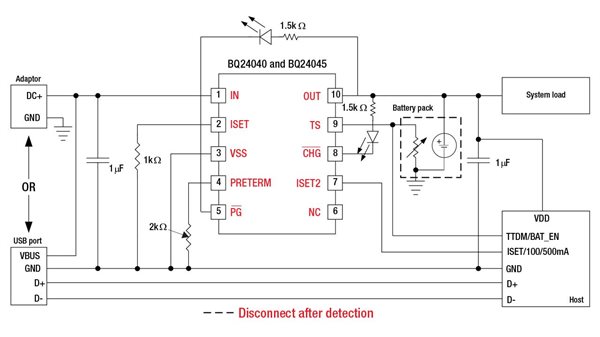

Electric masks are usually powered by single string of small lithium-ion (Li-ion) batteries, which are charged through a USB interface. TI’s BQ24040 battery charger is a good fit for this kind of system configuration. Figure 2 illustrates a typical application block diagram using this device.

Figure 2 BQ24040 block diagram

Figure 2 BQ24040 block diagramThe BQ24040 is an easy to use, high-precision, high-current battery charger designed for space-constrained portable products. The input voltage range (up to 30 V) enables battery charging not only through USB but also various low-cost adapters without being damaged. Its performance specifications enable its use in smartwatches, wristbands, Bluetooth® headsets and electric masks.

The BQ24040 offers:

- A maximum 1-A charging current to meet quick charging needs.

- Charging current control as low as 10 mA.

- A charging voltage accuracy of up to 1% in the full temperature range to significantly extend the battery’s lifespan.

- An integrated battery temperature monitoring function.

- Comprehensive safety protection performance.

- Packaging as small as 2 mm by 2 mm.

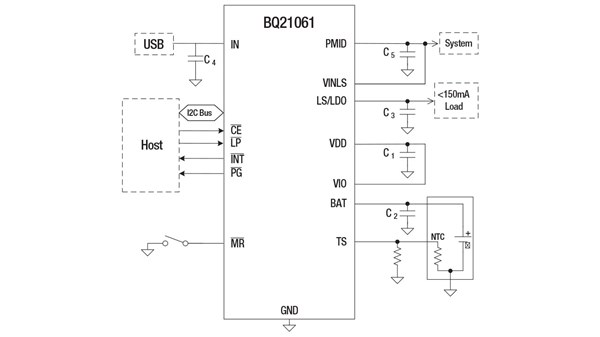

If you need an I2C-programmable Li-ion charger, consider the BQ21061, shown in Figure 3.

Figure 3 BQ21061 block diagram

Figure 3 BQ21061 block diagramThe BQ21061 is a highly programmable battery-management device that integrates a 500-mA linear charger for single-cell Li-ion batteries, a general-purpose low-dropout regulator (LDO) that is configurable as a load switch and a push-button controller. Through its I2C interface, the host may change charging parameters such as the battery regulation voltage and charge current, and obtain detailed device status and fault information. The push-button controller allows you to reset the system without any intervention from the host and wake up the device from ship mode. The BQ21061’s 10-nA ship mode extends battery life and supports immediate use of the battery.

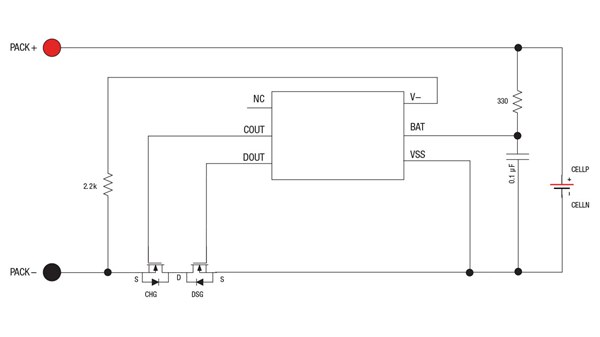

Battery protection scheme

Improper use of a Li-ion battery can lead to safety risks; therefore, protecting the Li-ion battery is crucial to a product’s safety performance. The BQ2970 provides protection functions for single-string low-voltage Li-ion batteries and lithium-polymer batteries and monitors the external power metal-oxide semiconductor field-effect transistor (MOSFET) to provide protection in cases of high charge and discharge currents, including overcharge, overdischarge, overcurrent and short circuits. The current consumed in normal-mode operation is 4 µA, reducing the battery’s power consumption. The size is 1.5 mm by 1.5 mm by 0.75 mm, which is conducive to reducing the volume of the battery pack. Figure 4 shows a typical application block diagram for the BQ2970.

Figure 4 BQ2970 reference schematic

Figure 4 BQ2970 reference schematicBLDC fan motor drive

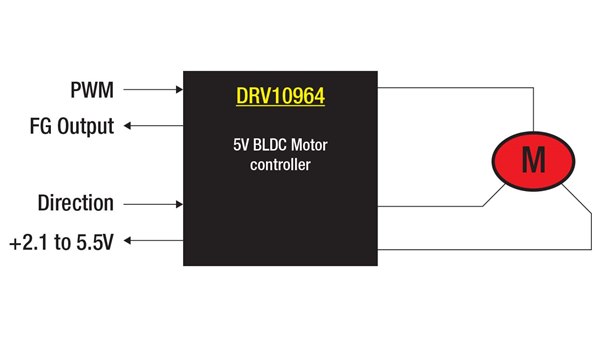

The good air permeability of an electric mask comes from its internal circulation fan. An efficient and silent DC brushless fan motor drive will directly affect the user experience with the mask. The DRV10964, shown in Figure 5, is a three-phase sensorless motor driver with an internally integrated power MOSFET. It is designed for motor-drive applications with high efficiency, low noise and few peripheral devices. A proprietary sensorless 180-degree sine control scheme provides ultra-silent motor-drive performance.

Figure 5 DRV10964 reference schematic

Figure 5 DRV10964 reference schematicThe DRV10964 offers:

- A 180-degree three-phase sine-wave drive without a Hall sensor, which can support a maximum 500-mA continuous working current.

- Locked rotor, overcurrent, overvoltage, undervoltage and overheating protection functions.

- Ultra-low static current as low as 15 µA.

- Packaging as small as 3 mm by 3 mm.

MCU main control scheme

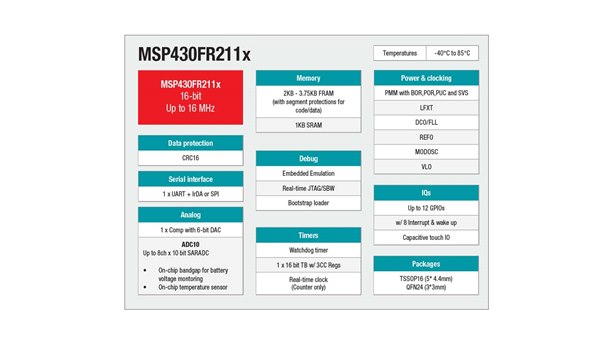

MSP430FR211x devices are part of the MSP430™ microcontroller (MCU) value line sensing portfolio. These ultra-low-power and low-cost MCUs offer up to 16MHz CPU frequency, memory sizes from 2KB to 3.75KB of FRAM unified memory and 1KB SRAM. FRAM technology combines the low-energy fast writes, flexibility and endurance of RAM with the nonvolatile behavior of Flash, allowing system engineers to increase performance while lowering power consumption.

Figure 6 Internal resources of the MSP430FR211x

Figure 6 Internal resources of the MSP430FR211xPower-rail scheme

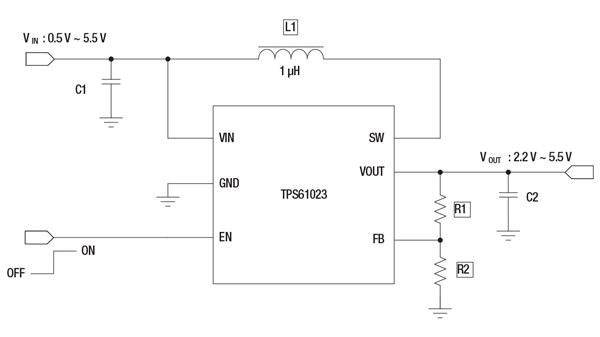

The system may need different power rails for an MCU or motor. To supply the MCU, an LDO can convert the battery power to 3.3 V. The TPS7A03 and TPS7A02 offers high performance with quiescent current as low as 200 nA and 25 nA respectively.

Figure 7 Typical application for the TPS61023

Figure 7 Typical application for the TPS61023TI’s comprehensive products give engineers the resources they need to design electric mask products. Our reference designs and support resources can greatly shorten development time and accelerate time to market for electric masks.