ZHCSM61C November 2014 – September 2020 CC3200MOD

PRODUCTION DATA

- 1 特性

- 2 应用

- 3 说明

- 4 Functional Block Diagrams

- 5 Revision History

- 6 Device Comparison

- 7 Terminal Configuration and Functions

-

8 Specifications

- 8.1 Absolute Maximum Ratings

- 8.2 ESD Ratings

- 8.3 Power-On Hours (POH)

- 8.4 Recommended Operating Conditions

- 8.5 Power Consumption Summary

- 8.6 Brownout and Blackout Conditions

- 8.7 WLAN RF Characteristics

- 8.8 Reset Requirement

- 8.9 Thermal Resistance Characteristics for MOB and MON Packages

- 8.10 Timing and Switching Characteristics

- 9 Detailed Description

- 10Applications, Implementation, and Layout

- 11Environmental Requirements and Specifications

- 12Device and Documentation Support

- 13Mechanical, Packaging, and Orderable Information

请参考 PDF 数据表获取器件具体的封装图。

机械数据 (封装 | 引脚)

- MOB|63

散热焊盘机械数据 (封装 | 引脚)

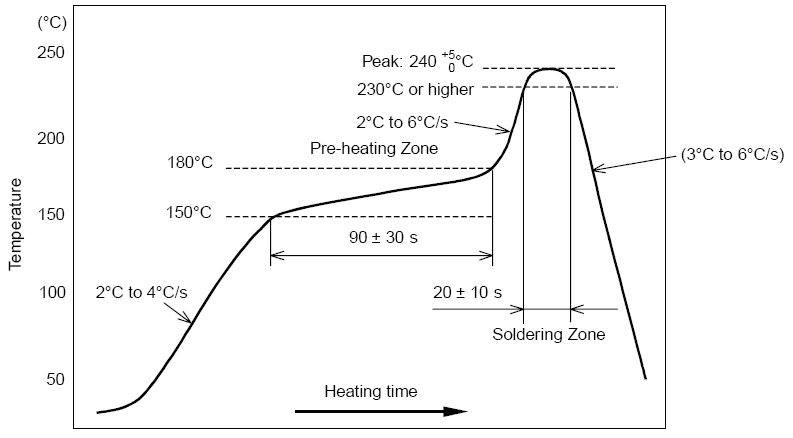

11.5 Soldering and Reflow Condition

- Heating method: Conventional convection or IR convection

- Temperature measurement: Thermocouple d = 0.1 mm to 0.2 mm CA (K) or CC (T) at soldering portion or equivalent method

- Solder paste composition: Sn/3.0 Ag/0.5 Cu

- Allowable reflow soldering times: 2 times based on the reflow soldering profile

(see Figure 11-1) - Temperature profile: Reflow soldering will be done according to the temperature profile (see

Figure 11-1) - Peak temperature: 245°C

Figure 11-1 Temperature Profile for Evaluation of Solder Heat Resistance of a Component (at Solder Joint)

Figure 11-1 Temperature Profile for Evaluation of Solder Heat Resistance of a Component (at Solder Joint)

Note:

TI does not recommend the use of conformal coating or similar material on the SimpleLink™ module. This coating can lead to localized stress on the solder connections inside the module and impact the module reliability. Use caution during the module assembly process to the final PCB to avoid the presence of foreign material inside the module.