-

Driving Daytime Running Lights LEDs With Thermal Foldback Reference Design

- 1 Overview

- 2 Resources

- 3 Features

- 4 Applications

- 5 Design Images

- 6 System Overview

-

7 System Design Theory

- 7.1 PCB and Form Factor

- 7.2 Optimizing Board Performance Based on LED String Voltage and Current

- 7.3 Switching Frequency

- 7.4 Output Overvoltage Protection (OVP)

- 7.5 Current Monitoring (IMON)

- 7.6 Thermal Foldback

- 7.7 Clock Generation (PWM)

- 7.8 Onboard Supply and Setting Duty Cycle

- 7.9 Buffering, Averaging, and Filtering

- 7.10 Boost Converter

- 8 Getting Started Hardware

- 9 Testing and Results

- 10Design Files

- 11Related Documentation

- 12About the Author

- IMPORTANT NOTICE

DESIGN GUIDE

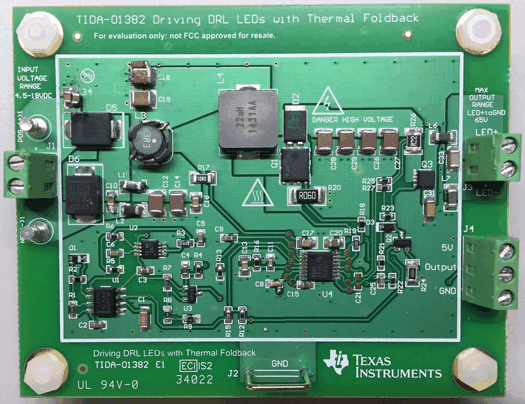

Driving Daytime Running Lights LEDs With Thermal Foldback Reference Design

1 Overview

The TIDA-01382 implements thermal foldback for derating current through the LEDs without using a microcontroller. This TI Design uses the following devices: the TPS92691-Q1 multi-topology LED driver in boost configuration to control the LEDs, the TLC555-Q1 LinCMOS™ timer together with the OPA2377-Q1 operational amplifier to measure and generate the accurate PWM signal by applying a feedback loop and a precision shunt regulator for setting the accurate duty cycle, and the LMT87-Q1 to implement thermal foldback. The input and output stage of the design is EMI- and EMC-filtered and can be directly supplied by a car battery.

2 Resources

| TIDA-01382 | Design Folder |

| TPS92691-Q1 | Product Folder |

| LMT87-Q1 | Product Folder |

| TLC555-Q1 | Product Folder |

| OPA2377-Q1 | Product Folder |

| TL431A-Q1 | Product Folder |

3 Features

- Thermal Foldback

- Precision PWM Dimming

- Efficiency-Optimized Design

- Operation Through Cold Crank

- Load Dump Tolerant

4 Applications

- Automotive Front Lighting

- Automotive Daytime Running Lights

- Automotive Tail and Brake Lights

5 Design Images

|

An IMPORTANT NOTICE at the end of this TI reference design addresses authorized use, intellectual property matters and other important disclaimers and information. |