SSZTCX6 April 2023 TPS7H5001-SP , TPS7H5002-SP , TPS7H5003-SP , TPS7H5004-SP , TPS7H5005-SEP , TPS7H5006-SEP , TPS7H5007-SEP , TPS7H5008-SEP , TPS7H6003-SP

In the satellite industry, dramatic increases in local data processing, support for higher throughput communication links and the rapid adoption of electrical propulsion systems are driving demand for much higher performance electrical power systems (EPSs). The EPS is part of the bus section of a satellite, providing structural support and housing subsystems such as power, thermal management, communication and propulsion. The EPS generates, stores, regulates and distributes power to all other subsystems and payloads onboard the satellite.

The unique challenges and constraints of space missions require optimizing size, weight and power (SWaP). Here are some of the reasons why SWaP is such a big deal in satellite designs:

- Mission requirements: Requirements such as data transmission rate, resolution and sensitivity can impact a satellite’s SWaP requirements.

- Launch limitations: Satellites have size constraints, weight constraints and cost-of-launch constraints that can be $10,00 to $1000,00 per kilogram based on the intended orbit.

- Power generation: Satellites generally rely on solar panels, and the size and weight of the panels limit the amount of generated power. The power-generation capacity also affects the weight and size of components, like batteries, and functions such as power distribution and thermal management.

- Operational efficiency: SWaP optimization enables satellites to operate more efficiently in space, resulting in better performance and longer mission lifetimes.

Because power is one of the most valuable resources on a satellite, maximizing EPS efficiency can help extend mission lifetimes, reduce mass and volume, and minimize thermal management overhead.

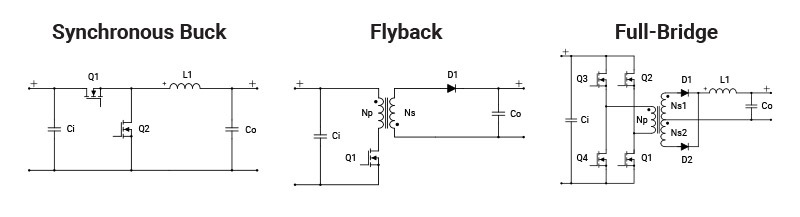

Beyond efficiency, an EPS must also handle a wide range of voltages and currents because of the number of power-supply topologies. Figure 1 shows some of the most common topologies.

Figure 1 Common power-supply topologies

in satellite power architectures

Figure 1 Common power-supply topologies

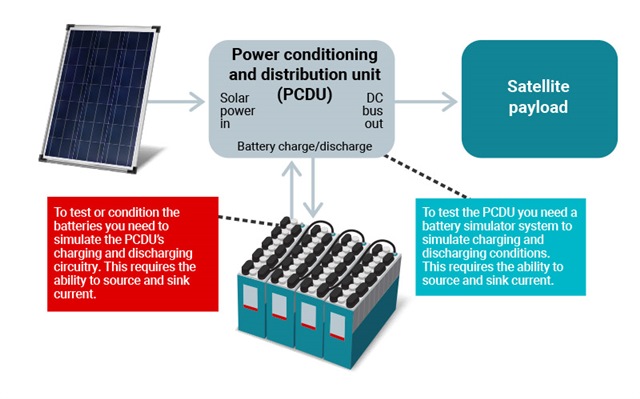

in satellite power architecturesThe components and functions, shown in Figure 2, of a typical satellite EPS are:

- Solar panels (or energy generation): Solar panels are the primary power source for most satellites.

- A battery (or energy storage): The battery stores excess power generated by the solar panels during daylight hours, and provides power to the satellite during an eclipse or when the solar panels are not generating enough power.

- Power-conditioning unit (PCU): The PCU regulates the electrical output of the solar panels and battery to provide a stable and consistent voltage and current to the rest of the satellite.

- Power-distribution unit (PDU): The PDU distributes power generated by the solar panels and battery to the various subsystems and payloads onboard the satellite.

- Backup power supply: If the primary EPS fails, a backup power supply will help maintain the most essential functions until the restoration of the primary system.

Figure 2 A typical satellite

EPS

Figure 2 A typical satellite

EPSOne way to optimize the SWaP design challenge in these types of systems is to use pulse-width modulation (PWM) controllers. For example, the radiation-hardened TPS7H5001-SP (100 krad TID, 75 MeV⋅cm2/mg) and radiation-tolerant TPS7H5005-SEP (rad-tolerant 30 to 50 krad TID, 43 MeV⋅cm2/mg) controller families enable the use of a common power architecture for many of the circuits in an EPS across a number of different missions and diverse orbits.

To help engineers optimize the SWaP in their satellite power system, the following reference designs use space-grade PWM controllers in various power-supply circuits across the satellite, not only in the EPS, but also on select payload boards:

-

Isolated flyback design:

- A 100-W isolated synchronous flyback topology that supports an input of 22 V to 36 V with an output of 5 V and uses GaN FETs in the power stage.

- This design is optimized for power-supply topologies that require only a single output.

-

Non-isolated high-current dual-phase buck design:

- This design uses the TPS7H5001-SP controller in a single-phase synchronous buck topology supporting an input of 11 V to 14 V with an output of 1 V and uses GaN FETs in the power stage. The design is capable of supporting 20 A and maintains tight DC and AC tolerance.

- You can extend this design to a multiphase solution optimized for payload designs that require high current (>50 A) and low input voltages (sub-1 V) to power the core rails of some advanced field-programmable gate arrays and multicore central processing units.

-

Non-isolated high-voltage buck design:

- A 200-W non-isolated synchronous buck topology that supports an input of 50 V to 150 V with an output of 28 V, using all radiation-hardened devices and radiation-hardened metal-oxide semiconductor field-effect transistors.

- This design is optimized for regulating the highly variable output of 100-V solar panels before the satellite passes the power to the battery storage portion of an EPS subsystem.

Conclusion

With power being one of the most valuable resources on a satellite, the EPS architecture can have a significant impact on the overall design. TI’s radiation-validated PWM controller families provide high efficiency and support a wide range of topologies, as well as an architecture that’s deployable in a diverse set of missions and orbits.

Additional resources

- Check out the TI Space Products Guide, Radiation Handbook for Electronics and Spacecraft Circuit Design Handbook.

- Watch our on-demand webinar, Basics of Flyback Power Converter Modeling in SIMPLIS for Satellite Applications.