SSZTCS2 april 2015 TMS320F280049C

In parts one, two, and three of his blog series, Yisong Lu discussed different “sensorless” start-up techniques for three-phase synchronous motors and specifically how these techniques are applied to the DRV10x series of integrated motor controllers. In this three-part blog series, I will discuss the start-up options for TI’s high-performance InstaSPIN-FOC™ solution.

Sensorless control has primarily been applied to applications where the majority of the operating time is at higher electrical frequencies (mechanical speeds). This is due primarily to the fact that most sensorless techniques require a back-EMF signal that is generated by the rotor’s rotation at a minimum frequency. With the FAST™ software observer used in the InstaSPIN-FOC solution, this minimum frequency of operation is much lower than other observers, sometimes below 1 Hz. But it still requires a minimum frequency.

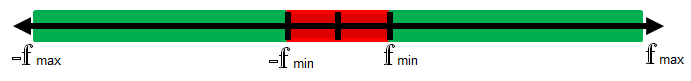

Figure 1 Frequency of operation for

FAST software observer

Figure 1 Frequency of operation for

FAST software observerThe default start-up capability of InstaSPIN-FOC is similar in concept to the methods discussed in parts I and II, however the unique capability of FAST to quickly (in less than 1 Hz) start providing accurate rotor angle estimation at very low rotor speeds means the technique being used to start-up only needs to be applied for a very short amount of time. This is a huge advantage in providing robust start-up, especially in applications with highly dynamic loads.

The primary start-up technique in InstaSPIN-FOC is called ForceAngle. ForceAngle is described in the InstaSPIN User’s Guide, primarily chapter 14.3.

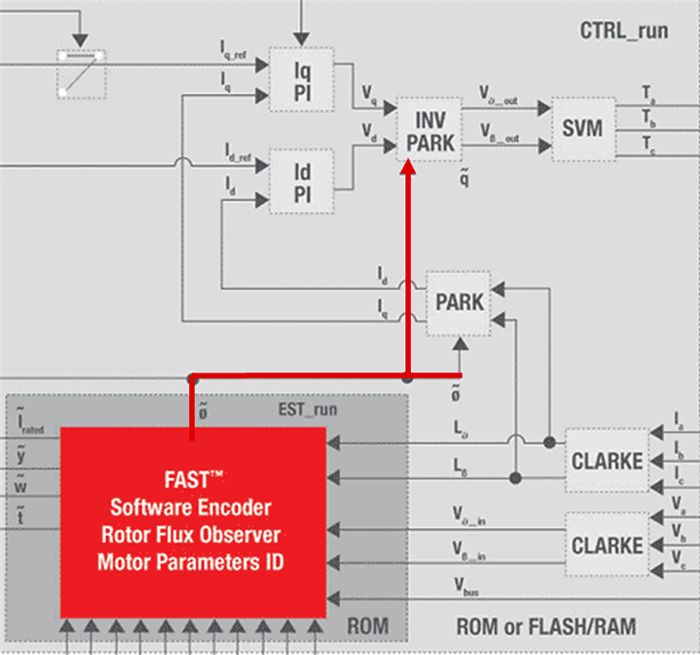

Figure 2 The estimated or forced rotor

flux angle used in the InstaSPIN-FOC system

Figure 2 The estimated or forced rotor

flux angle used in the InstaSPIN-FOC systemThe initial – and until enough Bemf is measured where FAST can start estimating correctly – rotor flux angle is unknown. With the ForceAngle software flag disabled, the angle output of the FAST observer is used in the field-oriented control system for the Park and Inverse Park transforms. Until FAST has enough Bemf voltage feedback, the estimates are unpredictable. But this estimated angle – even though incorrect – will be feeding the control system that will be applied to the motor and that may induce rotor movement. With just a small amount of rotor movement, enough Bemf voltage is produced where FAST can converge on a reasonable angle estimate, allowing controlled high-torque drive into an area of excellent operation. So if enough torque is generated for rotor movement, this method can be used to start the motor, but it may not be consistent in start-up performance.

To have a more regulated start-up, it is recommended to enable the ForceAngle flag. When ForceAngle is enabled, the estimated angle is generated by emulating the angle from a rotor moving at a fixed frequency, as set by the user through the variable USER_FORCE_ANGLE_FREQ_Hz. This emulated rotating angle is used until the frequency estimated from FAST is greater than a user prescribed limit set by USER_ZEROSPEEDLIMIT. It is always recommended to keep the FORCE_ANGLE_FREQ at least two times greater than the ZEROSPEEDLIMIT frequency to insure that the rotor will actually be driven beyond the low speed limit needed for FAST to generate a reasonable estimate.

For example, if it is determined in testing that FAST is providing reasonable estimates at 2 Hz, you would set the following two variables:

#define USER_ZEROSPEEDLIMIT (2.0 / USER_IQ_FULL_SCALE_FREQ_Hz)

// When ForceAngle flag is enabled USER_ZEROSPEEDLIMIT * USER_IQ_FULL_SCALE_FREQ_Hz = the frequency limit where FAST will be use instead of the ForcedAngle:

#define USER_FORCE_ANGLE_FREQ_Hz (4.0)

// Guarantees that the emulated excitation is larger than the frequency limit to provide more robust start-up.

Stay tuned to the next part of the series to learn about how to generate sufficient torque at start up and maximize it while spinning your motor.