SSZTC96 august 2015 DLP7000UV , DLP9500UV , DLPA200 , DLPC410

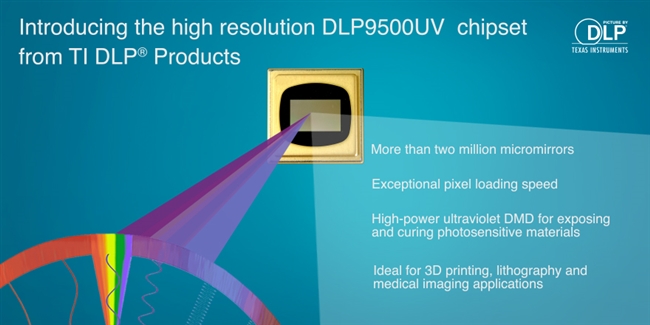

TI DLP® Products is reinforcing its reputation in imaging technology with the release of the DLP9500UV chipset. The latest addition to its portfolio features the highest resolution Ultraviolet (UV) DLP chip to quickly expose and cure photosensitive materials in industrial and medical imaging applications.

DLP Products is no stranger to working with UV imaging, having previously offered UV products to our DLP Design House partners. Along with the DLP9500UV, this fall we will offer a second UV chipset, the DLP7000UV, available publicly for developers.

Both the DLP7000UV and DLP9500UV digital micromirror devices (DMD) enable high resolution, fast-pattern switching speed, and are optimized for exposure in the 363 – 420 nm wavelengths.

While both chipsets offer low thermal resistance, high optical power (up to 2.5W/cm²), and a package window optimized for UV wavelength transmission, there are a few key differences between the chipsets that developers should note. If you’re looking for the fastest UV DLP chip available and one that is suited for mid-range platforms with a competitive price point, the DLP7000UV chipset is a great solution. But, if you want higher resolution with a pixel loading speed of up to 48Gps (Giga pixels per second) for fast production cycle times, you should consider the DLP9500UV chipset.

The DLP9500UV chipset boasts a powerful combination of resolution and speed for developers to get started. It has more than 2 million micromirrors (1920 x 1080) which enable end equipment to image large exposure areas with few print heads, and it supports print feature sizes approaching 1µm. Additionally, it’s combined with the DLPC410 Digital Controller, DLPR410 Configuration PROM, and DLPA200 DMD Micromirror Driver, which enable its fast micromirror loading speed.

This flexible solution can be used in a wide range of applications, including direct imaging lithography; 3D printing; laser marking; LCD/OLED repair; computer-to-plate printers for industrial applications; and ophthalmology, phototherapy and hyperspectral imaging for medical applications.

So, what does all this mean for developers? The DLP UV chipsets have already helped to make the production of printed circuit boards an efficient process with the unique patterning of the electronic designs and solder masks on boards. These efficiencies lead to a high output at a low cost. Adding the DLP7000UV and DLP9500UV to the TI DLP portfolio allows the chipsets to be accessible and available to developers.

Eager to get started with TI DLP Ultraviolet Solutions? Check out these resources:

- An overview page for DLP UV Solutions

- A video on High-power DLP UV Technology

- A video on DLP-enabled PCB lithography

- For MyTI users, an application note covering system design considerations using DLP technology in UVA