SSZTB25 july 2016

Testing switching power supplies includes many different tests, one of them being the output-voltage peak-to-peak ripple. Output-voltage ripple is the alternating current (AC) component of the direct current (DC) output voltage. It’s generated by a combination of factors, including the output capacitor’s equivalent series resistance (ESR), the voltage drop across the output capacitance, duty cycle and switching frequency.

Because it impacts the overall voltage tolerance of the rail, the peak-to-peak output-voltage ripple is a target specification in many processor, field-programmable gate array (FPGA), application-specific integrated circuit (ASIC) and system-on-chip (SoC) data sheets and design guides.

How you measure the ripple can affect your ability to meet the design requirements.

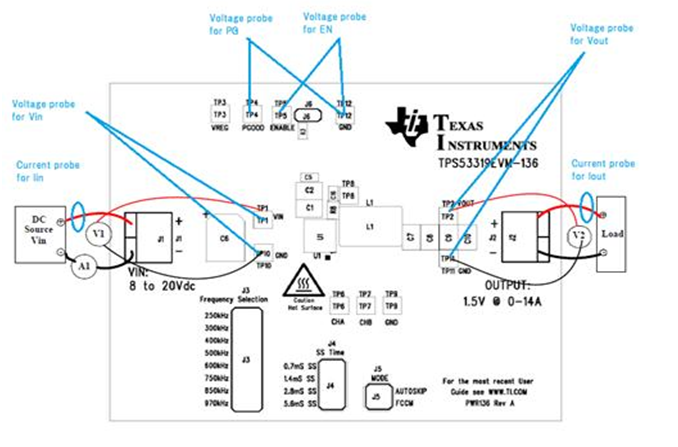

Figure 1 shows a typical output-voltage ripple probe setup.

Figure 1 Output-voltage Ripple Probe

Setup

Figure 1 Output-voltage Ripple Probe

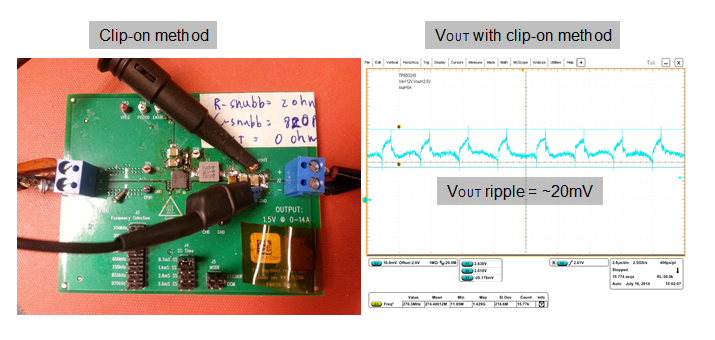

SetupProbing using a clip-on probe shows an increased ripple that may be partly the result of the ground-wire loop picking up noise, as shown in Figure 2.

Figure 2 Output Voltage Ripple Probe

with a Clip-on Probe and Ground Wire Fully Extended, Picking up Noise from the

Nearby Switch Node

Figure 2 Output Voltage Ripple Probe

with a Clip-on Probe and Ground Wire Fully Extended, Picking up Noise from the

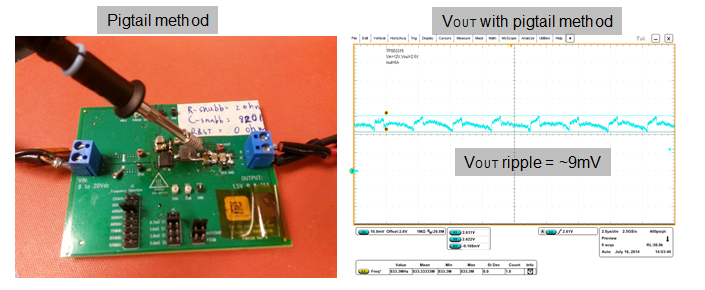

Nearby Switch NodeProbing using the pigtail method improves ripple, even though the tip is again near the switch node, as Figure 3 shows. The ground loop is much shorter; thus the noise pickup is less severe.

Figure 3 Output-voltage Ripple Probe

Using the Pigtail Method; the Probe Ground Is in Contact with the Pigtail, Which

Is Connected to the Board Ground

Figure 3 Output-voltage Ripple Probe

Using the Pigtail Method; the Probe Ground Is in Contact with the Pigtail, Which

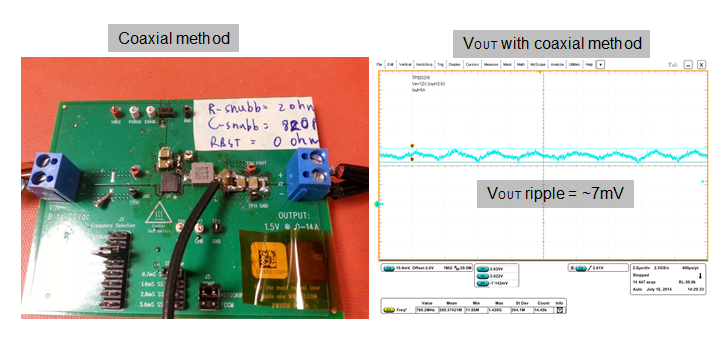

Is Connected to the Board GroundUsing a coaxial cable method improves results even more, as Figure 4 shows. Directly soldering the woven copper shield on the board ground minimizes the ground loop further.

Figure 4 Output-voltage Ripple Probe

Using Coaxial Method

Figure 4 Output-voltage Ripple Probe

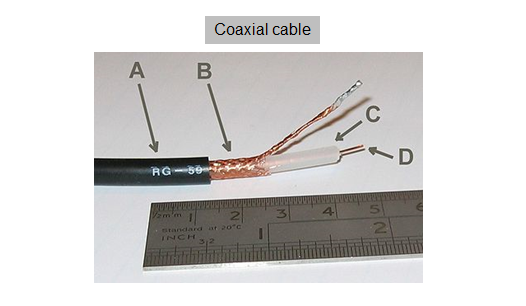

Using Coaxial MethodFigure 5 shows a close-up of the coaxial cable.

Figure 5 Coaxial Cable Close-up: the

Outer Plastic Sheath (a); Woven Copper Shield (Ground) (b); Inner Dielectric

Insulator (c); and Copper Core (vOUT) (d)

Figure 5 Coaxial Cable Close-up: the

Outer Plastic Sheath (a); Woven Copper Shield (Ground) (b); Inner Dielectric

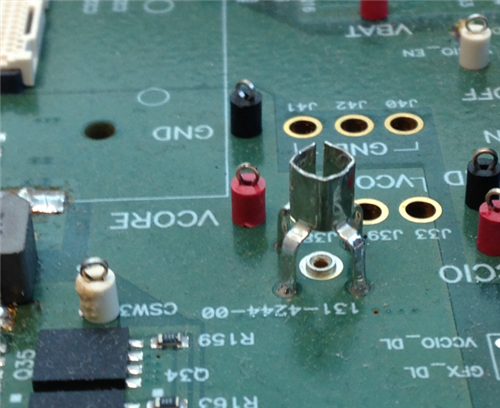

Insulator (c); and Copper Core (vOUT) (d)Another similar measurement method is to use a probe jack like that shown in Figure 6. The outside jacket is the ground connected directly on the board while allowing the probe tip to connect to the voltage test point.

Figure 6 Probe Jack

Figure 6 Probe JackOf all of these methods, using a differential probe is probably the best way to measure ripple accurately. It can eliminate the ground-loop noise pickup error, especially when connecting other electronic equipment to the same board ground (such as electronic loads and multimeters).

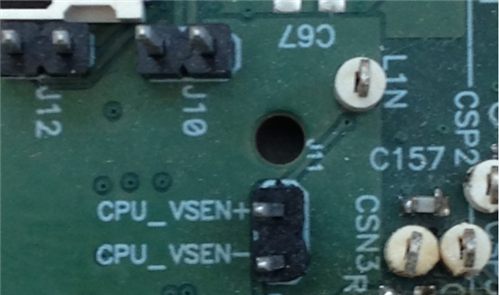

Figure 7 shows the two test points for differential probe connections on the board.

Figure 7 Differential Probe Test Points

CPU_VSEN+ and CPU_VSEN-

Figure 7 Differential Probe Test Points

CPU_VSEN+ and CPU_VSEN-If you are trying to meet tight output-voltage regulation requirements and have a low peak-to-peak voltage-ripple target, how you measure the ripple on your board can make you or break you. Optimizing your probe method will help you with your measurements and meet the specifications. Practice and compare any of the probe methods discussed in this post on a switching regulator evaluation module (EVM) like the TPS40304EVM-353. As well, read the application report, “Output Ripple Voltage for Buck Switching Regulator” and understand how ripple voltage is calculated and reported in WEBENCH® Power Designer.