SSZTAZ2 August 2016 LM5160 , TPS65130

Reducing solution size, component costs and power losses are getting more and more important in industrial applications. Analog I/O modules for Programmable Logic Controllers (PLC) are a good example for a need to meet those requirements.

Industry 4.0 describes a trend towards further automation combined with intelligent communication. As a result, PLCs need to be equipped with more I/O ports in process engineering, industrial automation and facility management. If space is limited, the controller cannot take up more real estate, so we have to increase module density to support the increasing I/O demand. An optimized power design can clearly contribute to these targets.

Let’s have a look on the power requirements and the power design of analog I/O modules.

Figure 1 PLC I/O Module Array

Figure 1 PLC I/O Module ArrayAnalog I/O modules typically signal with a 4-20mA current loop or +/-10V. We need DACs/ADCs for the conversion, typically supplied by 5V. To protect, but also to ensure the required performance is met, the power-supply rails need to be isolated to cancel out ground shifts or noise.

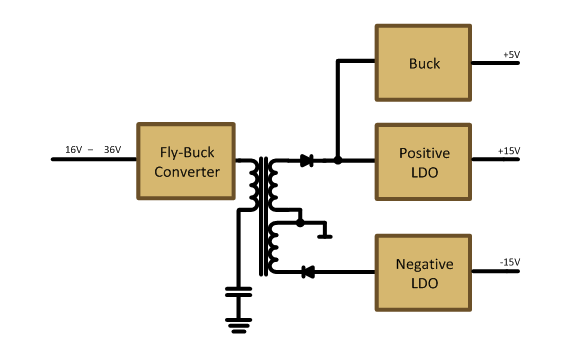

Thus, analog I/O modules need a 5V rail and a +/-12 to +/- 15V split-rail for voltage signaling or sourcing/sinking with the current loop, supplied isolated from a 24-V rail. Figure 2 illustrates an ordinary implementation.

Figure 2 ORdinary Power Supply

Implementation

Figure 2 ORdinary Power Supply

ImplementationIs there room to optimize the power supply and its design?

Analyzing for where to improve best, the transformer stands out as a candidate. With its two secondary windings, the production costs and footprint will be large. More importantly, its profile height is around 5mm. Space savings will enable smaller switching cabinets or more I/O modules, reducing cost significantly as well. Ideally, the active modules could be as thin as passive terminals. Consequently, the profile height of the board needs to be reduced.

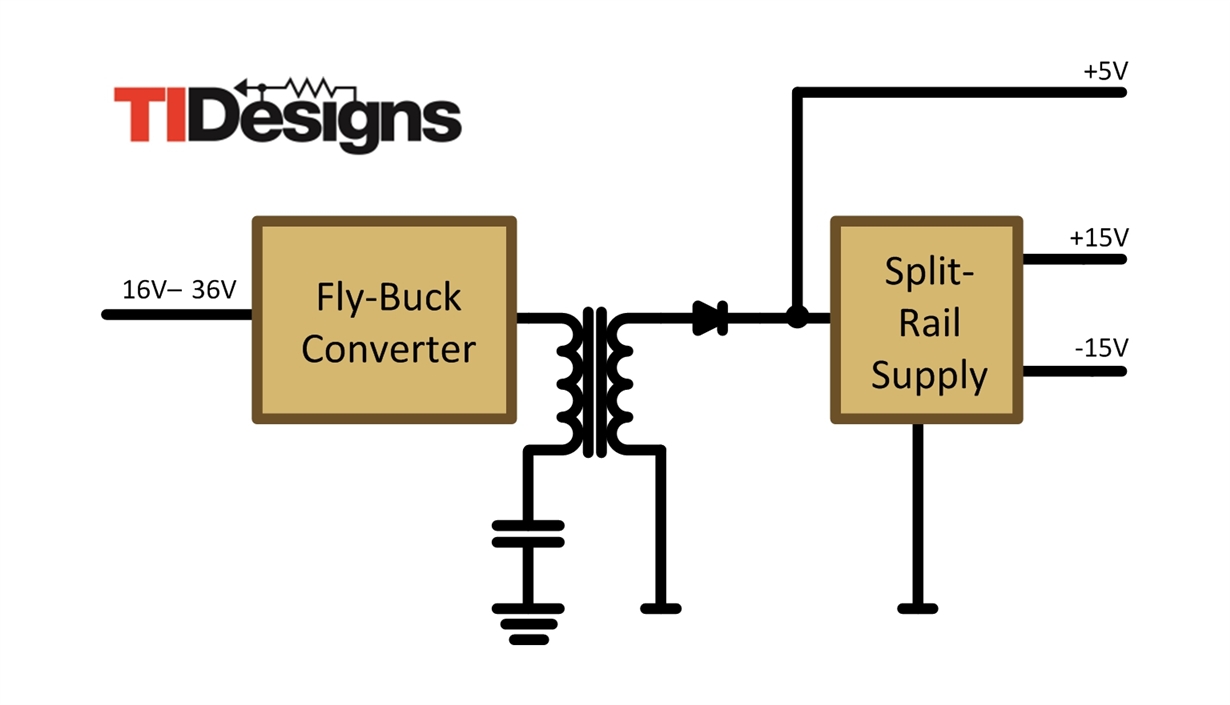

Let’s start with that thought. If we use a 1:1 transformer with a single secondary winding, you could actually pick a cost-optimized component with a profile height of only 1.8mm in a fly-buck converter configuration. Setting the LM5160 fly-buck converter output to 5V, you can eliminate the buck converter. To generate the +/- 12V to +/- 15V split-rail outputs, the all-integrated TPS65130 split-rail converter enables further optimization. This device integrates a boost converter for the positive voltage output and an inverting buck-boost stage for the negative voltage output. Since its output voltages are regulated individually and tightly, there is another positive side-effect: We can eliminate the two LDOs.

From a power-conversion-efficiency perspective, there is a disadvantage that the split-rail goes through two conversion stages. However, the 5V rail is now optimized - it was going through two stages in the first design. Also the need for the two LDOs is gone, with approximately 2V dropout voltages each. So the power loss from the LDOs that had been contributing to heat in the system is gone, too.

Figure 3 illustrates the new solution.

Figure 3 New Power Supply

Implementation

Figure 3 New Power Supply

ImplementationThis solution needs only two active devices and has a 1.8mm maximum component height, which is so flat one could slide it under a door. The required board space is shrunk to 50%. It enables the building of extremely thin analog I/O modules at optimized costs. The output voltages are accurately regulated and have a very low 5mV voltage ripple.

This concept is available as a Small Footprint Isolated Analog DC/DC Converter Reference Design (TIDA-00689), including the system description, schematic, layout proposal and bill of materials. The test report contains test data and thermal measurements.