SSZTAR2 october 2016 LM25037-Q1 , UC3525A , UC3846 , UCC28083

For those of you who don’t know me, let me get the formalities out of the way. I absolutely love digital control! You know, stuff like z-transforms, Kalman filters, nonlinear control, adaptive control and ultimately the ability to customize a power-supply solution.

Before you say anything, let me point out that I know I’m an uber geek – but you have to admit that this stuff can be really cool (and of course, really useful). One of the principle ways that digital control is useful is that you can take a pre-packaged controller and add to it or modify it to meet end-solution requirements that may not have been explicitly envisioned by the original device architects. To that end, digital controllers are a power-supply designer’s dream come true.

But let’s be honest: digital control also has some overhead that some of us don’t like or are just not equipped to deal with. In my opinion, that is where a general-purpose pulse width modulation (PWM) can step in and really shine. These devices have been around for some time, and have in many respects served as the workhorse of the power-supply industry. They have a significant track record of outstanding performance and a long list of proven capability of adapting to a designer’s needs. From this vantage point, PWMs kind of look like the analog controller’s version of digital control. In many applications, this can be exactly what a power-supply designer needs: flexibility without complexity.

For example, take the UC3846 or the UC3525A. Many of you probably cut your teeth in power-supply design using one of these devices. Their continued popularity speaks volumes to their reliability and robustness. From an application standpoint, these devices are routinely used for boost, buck, flyback, forward, full bridge, half bridge, peak current-mode, voltage-mode and input-voltage feed-forward use cases in end equipment such as welding, telecom, industrial, lighting and aerospace. I’m sure many of you are thinking of several other topology/application variations you’ve been able to use these parts for. Their flexibility makes the UC3846 or the UC3525A fundamental power-supply building blocks with which you can create dozens of application variations.

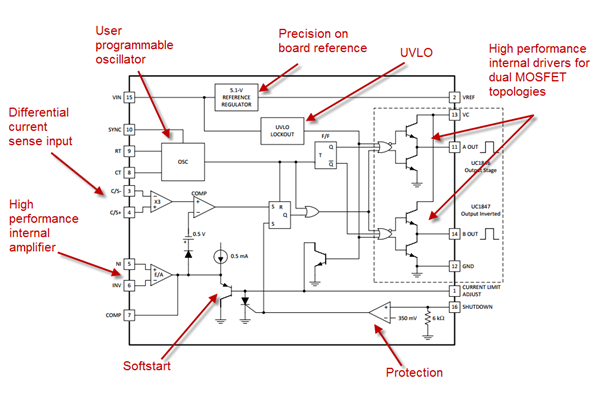

Take a look at what’s under the hood of one of these devices.

Figure 1 UC3846 Block Diagram

Figure 1 UC3846 Block DiagramYou have drivers, control and protection: all of the key must-have elements. Because you have access to the key comparator and amplifier inputs and outputs, you have a tremendous amount of freedom to make the device do precisely what you need it to do. Here are a few examples I can think of off the top of my head:

- Summing the C/S inputs with the RT/CT ramp enables peak current-mode control with slope compensation.

- Directly feeding the C/S inputs with a ramp achieves voltage-mode control. If you make this ramp proportional to the input, you have input voltage feed-forward on a cycle-by-cycle basis.

- The internal operational amplifier has its input and outputs exposed for complete customization of the compensation.

- You can use the external circuits for pull down or up on the COMP pin to shut down or introduce some flavor of nonlinear control.

While that doesn’t necessarily have the same level of flexibility found in digital control, it brings a boat-load of similar flexibility benefits that excite a geek like me.

What kind of uses do you have for general-purpose PWM controllers? What flexibility do you value most in these kinds of devices? I’d love to hear your thoughts on this subject in the comments section.

TI has a large selection of general-purpose PWM controllers to satisfy your every need, from the eight-pin UCC28083 to the automotive-qualified LM25037-Q1.

Additional Resources

- Discover TI’s portfolio of PWM controllers.

- Read other blog posts about analog controllers: