SSZT593 november 2018 MSP430F6736A , MSP430F6779A , MSP430I2041

Over the last decade, electronic electricity meters, or e-meters, have replaced conventional electromechanical meters across today’s electric grid. This shift has led to increased accuracy and features, reduced cost and size, and enabled a smarter grid.

As shown in Figure 1a, electromechanical meters are identifiable by their rotating disks and gauges, while the e-meters shown in Figure 1b are identifiable by their LCDs.

Figure 1 Electromechanical Meters (a);

and E-meters (b)

Figure 1 Electromechanical Meters (a);

and E-meters (b)Although both types of meters measure active energy, e-meters can calculate other important parameters, such as voltage, current, power, reactive energy, frequency, power factor and phase angle, whereas electromechanical meters cannot. These parameters provide extremely insightful information to energy consumers and utility providers by indicating power quality, power outages, load balancing and tampering.

Energy measurement is primarily used in e-meters to bill consumers, identify load conditions and monitor faults. However, the expanding emphasis on energy conservation, smart city initiatives and load disaggregation requires more equipment to accurately measure energy, including sub-meters, smart plugs, server power monitors, protection relays, fault indicators and circuit breakers. For example, today’s smart appliances feature embedded metering plus wireless connectivity that can improve efficiency and controllability. Whether you’re a homeowner or business owner, you can conserve energy by remotely monitoring and managing these types of appliances, as shown in Figure 2.

Figure 2 Example of Viewing Power

Consumption for Smart Appliances with Embedded Metering

Figure 2 Example of Viewing Power

Consumption for Smart Appliances with Embedded MeteringAn appliance is just one example of a load. It’s possible to classify most loads and sources into single-, dual- and three-phase configurations. In most homes, single-phase AC mains deliver one voltage, typically between 110 V and 230 V, referenced to neutral. Current consumed by the load depends directly on the type of equipment used. Power is the instantaneous sum of products of the AC voltage and current. When the power is averaged over time, it equals energy.

You can easily calculate power and energy using one of TI’s MSP430™ microcontrollers (MCUs). MSP430F67xxA and MSP430i20xx MCUs feature high-performance 24-bit sigma-delta analog-to-digital converters and other integrated analog and digital modules that capture and process AC waveforms to calculate power, energy, and other parameters.

Engineers designing embedded metering applications may have limited experience working with MCUs, developing algorithms or processing complex signals. Hardware design challenges include implementing the analog front-end circuitry for the type of voltage and current sensors selected. Software design challenges include configuring and synchronizing the MCU’s modules and optimizing calculations to achieve a comprehensive set of accurate and stable results. System-level design challenges may be the most difficult – integrating everything, implementing and performing calibration, and migrating between MCUs across single- and poly-phase configurations.

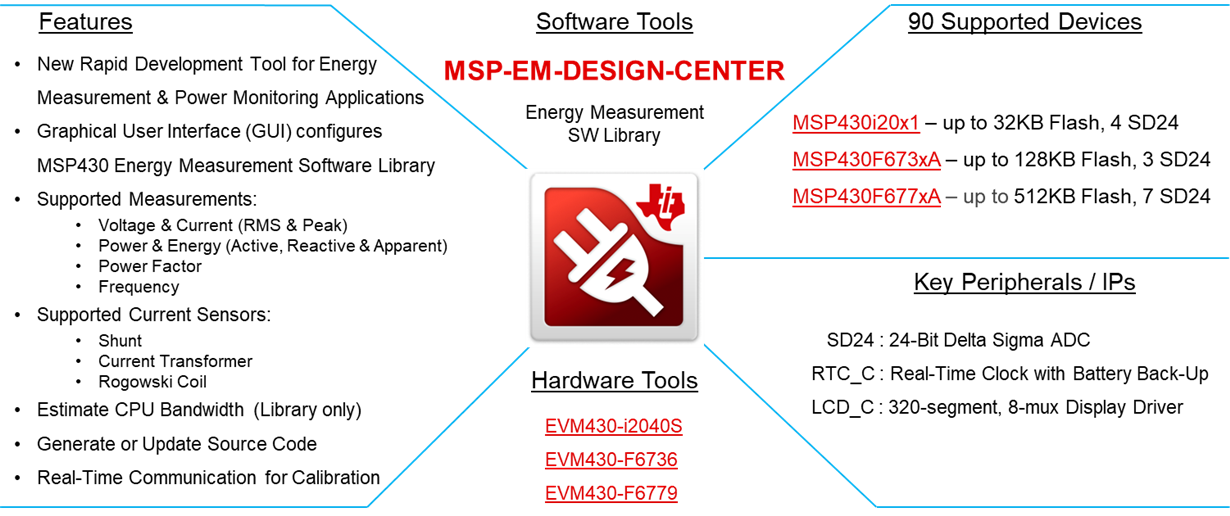

Figure 3 summarizes the new Energy Measurement Design Center (EMDC) graphical user interface (GUI) and software library, which TI developed to simplify, automate and accelerate these embedded metering designs. Rather than developing everything behind the embedded metering functionality, you can use the EMDC and focus on developing other features such as wireless connectivity. In fact, it’s possible to shorten the design time from months to days.

Figure 3 EMDC Overview

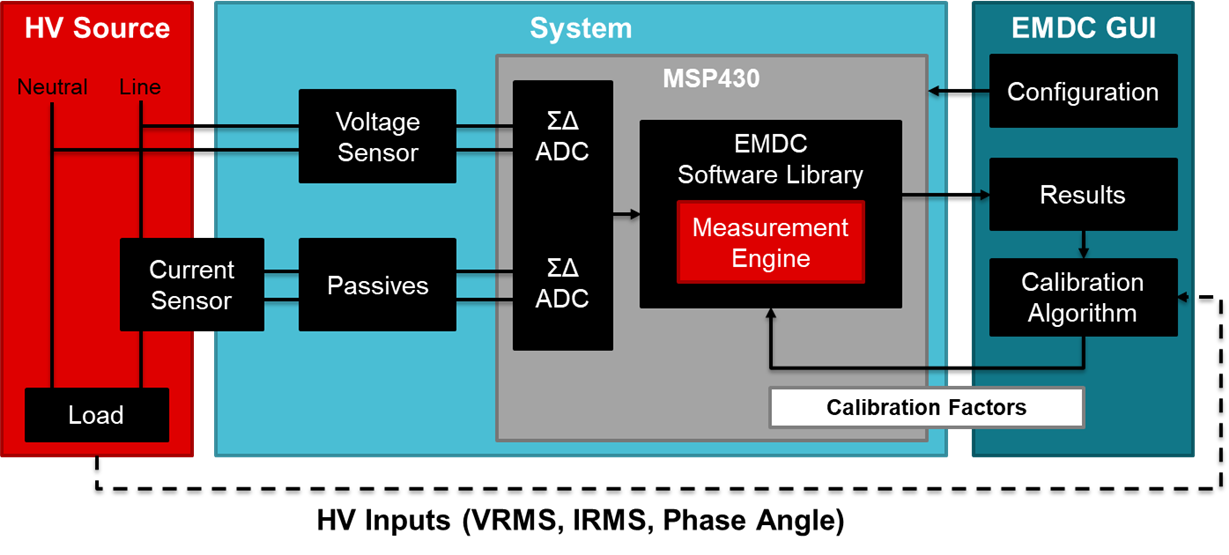

Figure 3 EMDC OverviewFigure 4 shows the three main components in an embedded metering system. First, the high voltage source can be accurate test equipment or AC mains. Next, the system can be an evaluation module or custom board that includes the MCU and sensors. Finally, a GUI or host MCU controls and communicates with the MCU in the system. Here, the EMDC GUI configures the software library, estimates the central processing unit bandwidth, checks for configuration errors, generates the source code for the MCU, calibrates the system and displays the results – all without you writing a single line of code.

Figure 4 Embedded Metering System Block

Diagram for a Single-phase Configuration

Figure 4 Embedded Metering System Block

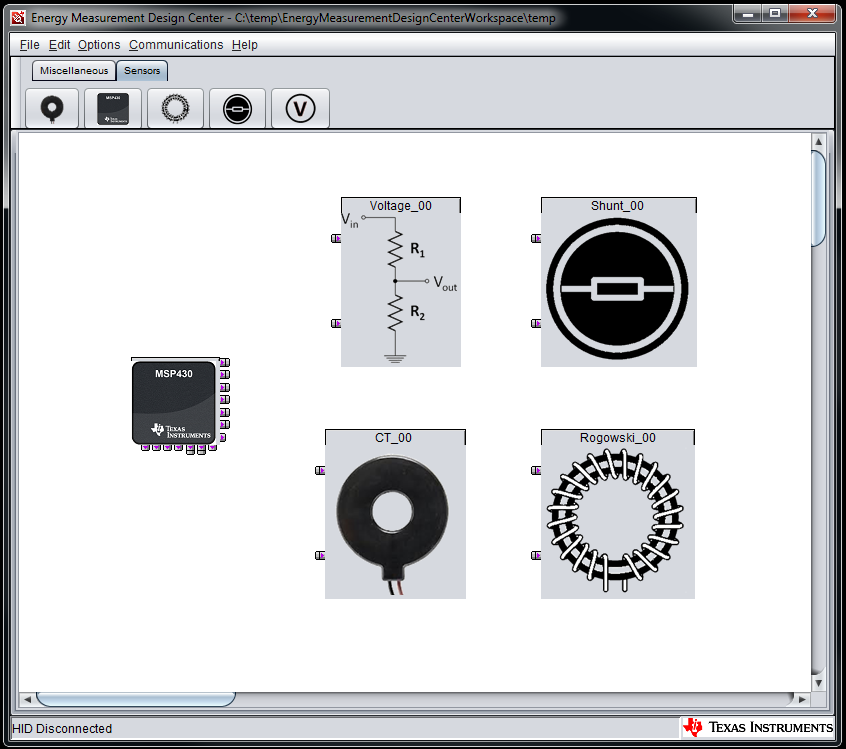

Diagram for a Single-phase ConfigurationInside the EMDC GUI shown in Figure 5, there are icons representing the MCU and sensors, which you can drag and drop according to your system configuration. A drop-down menu enables you to migrate between supported MCUs.

Figure 5 EMDC GUI with MCU and Sensor

Icons

Figure 5 EMDC GUI with MCU and Sensor

IconsFor more information about how to use this free tool in your designs, download the EMDC GUI and software library, learn about the dependencies and supported evaluation modules, or leverage the pre-configured, pre-calibrated projects and associated binary images. You can also modify these EMDC projects if your design is similar or start a new project if it’s different.

Together, these resources can help you quickly and easily evaluate the performance of TI solutions and jump-start your design.

Additional Resources

- Check out the Energy Measurement Design Center (EMDC) for MSP430 MCUs product folder

- Read the EMDC Technology Guide

- Download the EMDC API Guide

- Watch the EMDC Training Series