SSZT550 january 2019 TPD6S300 , TPD6S300A

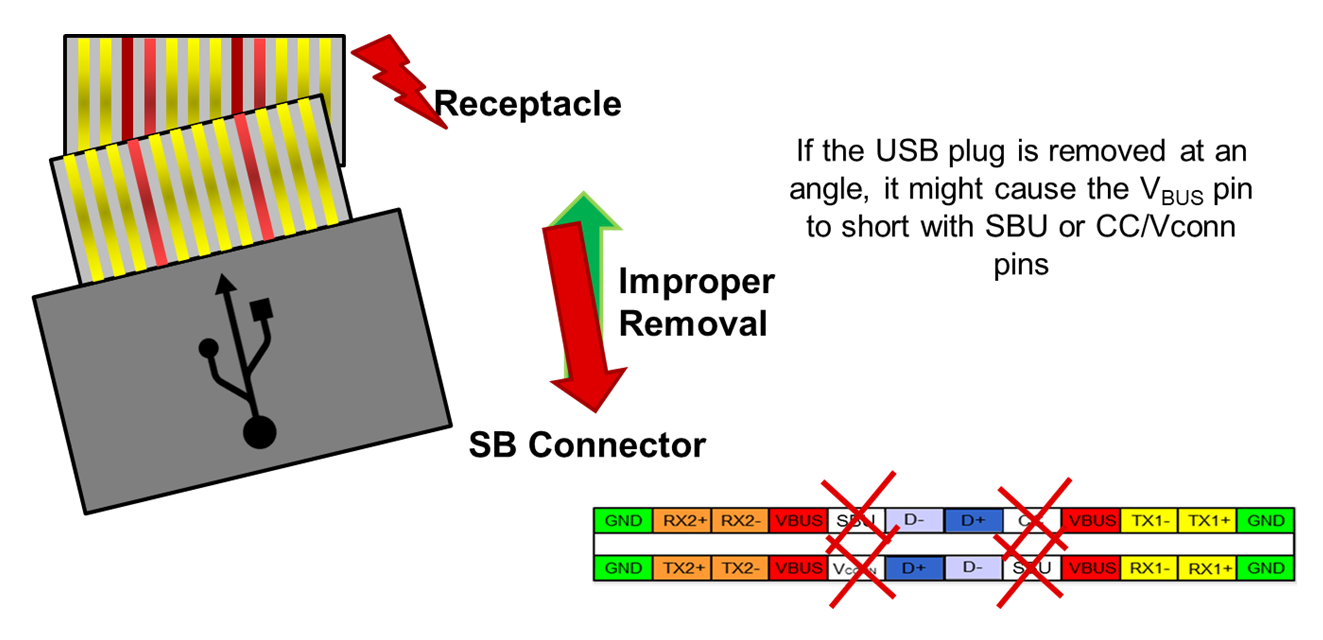

Due to the smaller connector/receptacle size and reduced pin pitch, USB Type-C presents several new failure scenarios that can damage downstream circuitry. The most common failure scenario is mechanical twist; see Figure 1. Once a USB PD contract >5 V (such as 20 V, 15 V or 9 V) has been received by the USB PD Controller, if the USB plug is removed at an angle, it might cause the USB Type-C connector’s bus power lines (VBUS) to short with the adjacent pins – or more specifically the configuration channel (CC) and sideband use (SBU) lines.

Figure 1 Mechanical Twist Failure Scenario

Figure 1 Mechanical Twist Failure ScenarioWhy does this matter? Well, for most systems, the downstream circuitry (or USB Type-C/USB PD controller) is rated for only 6 V maximum on the CC/SBU pins. Engineers have two choices: add an external protection chip or select a USB Type-C/USB PD Controller with CC/SBU lines rated for 24 V or more. Let’s look into why forgoing the protection chip may not be the best idea.

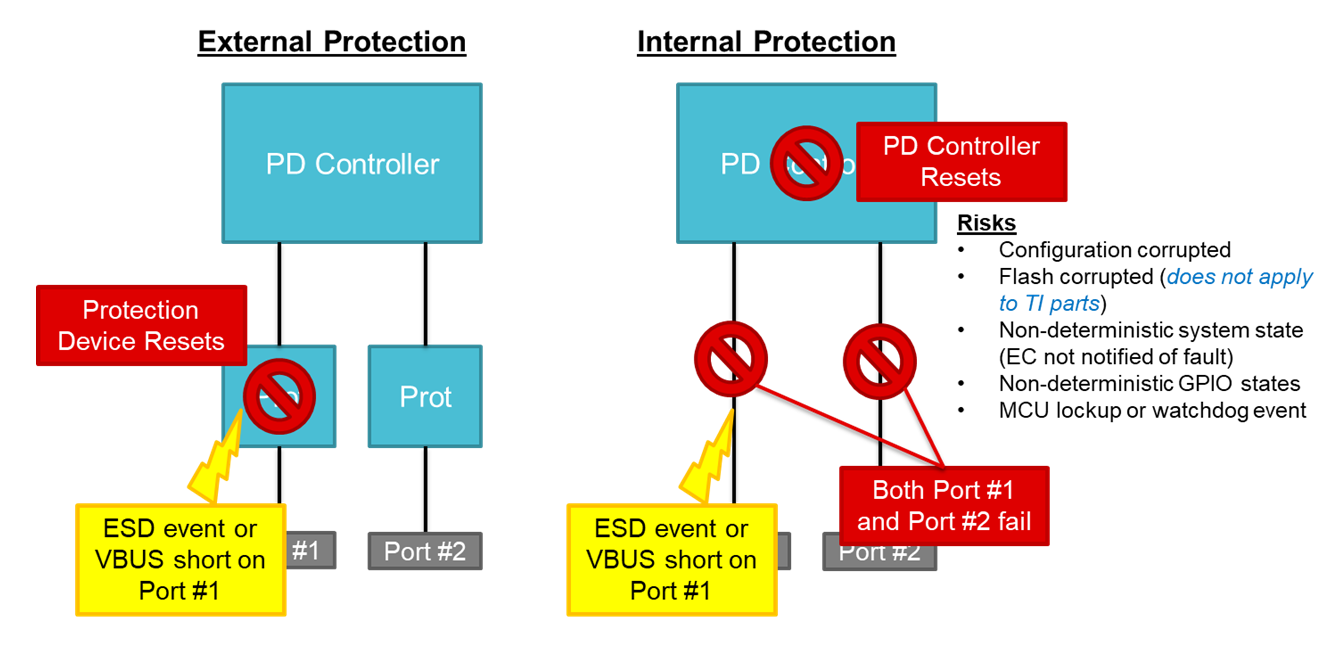

External protection works because if there’s an electrostatic discharge (ESD) event or VBUS shorting on port No. 1, the protection chip opens series field-effect transistors – thus isolating the high voltage from the rest of the system. The chip also dissipates any residual energy (on both system and connector sides) through internal clamping diodes. Then, the protection device resets and protects the rest of the system.

Internal protection doesn’t work because in the case of an ESD event or VBUS short on Port No. 1, the USB PD controller resets itself, bringing down both port No. 1 and port No. 2 as seen in Figure 2. In addition, the USB PD controller runs the risk of having the configuration or flash corrupted during this high rate of voltage change (dv/dt) event. It could leave the system in a nondeterministic state with unknown general-purpose input/output values or even cause the microcontroller to lock up. Even worse, if the USB PD controller doesn’t have properly designed internal clamps to absorb the energy, the device itself could be damaged.

Figure 2 External Protection Offers Fault Isolation

Figure 2 External Protection Offers Fault IsolationThese failures are easily avoidable by adding an external protection device such as the TPD6S300A. The TPD6S300A’s ability to clamp the voltage quickly and efficiently helps enable a robust and reliable solution for designers.

Additional Resources

- Read more about this topic in the white paper, “Circuit Protection for USB Type-C.”

- Download the TPD6S300A USB Type-C™ Port Protector: Short-to-VBUS Overvoltage and IEC ESD Protection datasheet.

- Jump-start your design with the TPD6S300 USB Type-C™ Overvoltage and IEC ESD Protection Evaluation Module and Short protection over Type-C port reference design.