SSZT217 december 2020 MSP430I2020 , MSP430I2021 , MSP430I2030 , MSP430I2031 , MSP430I2040 , MSP430I2041

When designing a system, the main goal is to meet high performance requirements at a low overall cost. It’s a delicate balance that influences the architecture of the whole system. Many systems, such as field transmitters, thermometers and electricity meters (also called e-meters) include at least one sensor, which may require an analog front end (AFE) as well. However, simply choosing a fixed-function AFE may not unlock the full potential of your design.

Design choices and flexibility trade-offs

Typically, you select a host microcontroller (MCU) or processor first as the foundation for your design, and then select other building blocks such as power, protection, communication and signal-chain components. If the system includes sensors with low-amplitude or differential outputs, you would probably pick a sigma-delta (also called delta-sigma) analog-to-digital converter (ADC) as the AFE. There are several common AFE options from which to choose, including:

- Discrete sigma-delta ADCs

- Application-specific integrated circuits (ASICs)

- Low-cost MCUs with an integrated sigma-delta ADC

Discrete sigma-delta ADCs

The simplest AFE option is a discrete (or standalone) delta-sigma ADC. While these ADCs offer superior precision and accuracy, they are the least flexible AFE option. These fixed-function ADCs communicate with the host MCU or processor over a common communication interface such as Serial Peripheral Interface (SPI), Inter-Integrated Circuit (I2C) or Universal Asynchronous Receiver/Transmitter (UART). The host is responsible for configuring the ADC and then processing the raw sensor data from the ADC.

ASICs

An ASIC is another AFE option that may include sigma-delta ADCs and other integrated modules that process the sensor data before sending it to the host. These devices vary in complexity but are fixed function. The host MCU or processor configures the ASIC similar to a discrete ADC, but the ASIC offloads some or even all of the data processing from the host, which can free up additional bandwidth and separate certain functions or calculations.

Low-cost MCUs

The most flexible AFE option is a low-cost MCU with integrated sigma-delta ADCs. These MCUs are not fixed function, so they can be programmed to operate like a discrete ADC (sending raw sensor data to the host) or an ASIC (processing the data before sending it to the host). Additionally, these MCUs can perform other valuable housekeeping tasks such as toggling LEDs or controlling other devices in the system.

Another advantage includes the flexibility to add new or advanced features by simply reprogramming them rather than physically replacing the discrete ADC or ASIC in the system. This flexibility also enables these MCUs to be used as AFEs in designs such as thermostats and weighing scales.

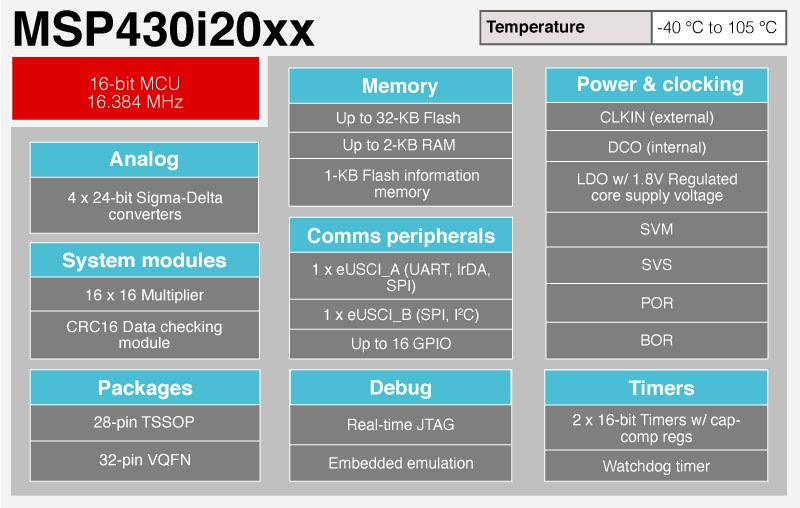

The MSP430i20xx family includes low-cost MCUs like the MSP430i2041, with as many as four 24-bit sigma-delta ADCs and as many as 16 input/output pins. Also, these MCUs feature an integrated 16.384MHz digitally controlled oscillator (DCO), eliminating the need for an external crystal and reducing overall cost. Figure 1 shows technical specifications for the MSP430i20xx family.

Figure 1 MSP430i20xx MCU technical specifications

Figure 1 MSP430i20xx MCU technical specificationsAdditional sensing applications

Several example applications demonstrate the flexibility of MSP430i20xx MCUs. These MCUs can act as an AFE for infrared temperature sensors and battery voltage monitors. They can also act as an AFE in embedded metering applications to measure the power or energy consumption of a load. Using the Energy Measurement Design Center (EMDC) graphical user interface (GUI), you can easily configure the MCU’s software to support several types of current sensors, including shunts, current transformers and Rogowski coils. In this case, the MCU functions like an ASIC by capturing the sensor data, performing the metering calculations, and sending that data to the host MCU or processor.

Let’s say that you wanted to include power quality features such as sag and swell detection in your metering design. You can use the same MCU and simply modify the software generated by the EMDC GUI to add that functionality. If you want to add more advanced power quality features such as harmonic detection to the same metering design a few years later, you could use the same MCU and modify the software to send the raw ADC samples to the host for harmonic analysis.

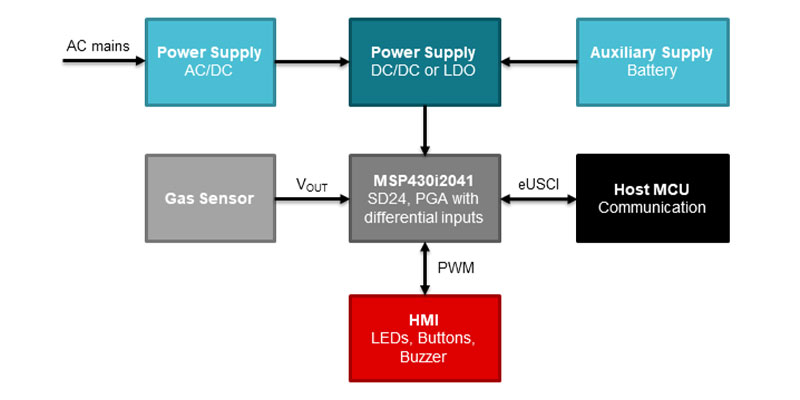

As a low-cost MCU with integrated sigma-delta ADCs, MSP430i20xx MCUs such as the MSP430i2041 are a good fit for field-transmitter applications such as pressure, flow, temperature and gas transmitters. Using gas transmitters as an example, Figure 2 shows how the MCU can capture data from the gas sensor and also support a human machine interface by controlling LEDs and a buzzer, increasing overall flexibility. This example demonstrates how you can easily offload some simple functions from the host onto the MSP430i2041 MCU.

Figure 2 Gas transmitter block diagram

Figure 2 Gas transmitter block diagramFor more information, watch the MSP430i20xx Sigma Delta ADC GUI Demo video.

Conclusion

MSP430i20xx MCUs are low-cost, versatile and can be integrated into various sensing applications. Get started today by using our hardware and software development tools and other resources that may interest you.

Additional Resources

- Start developing with the 32-pin target development board for MSP430i20xx MCUs or the MSP430i2040 submetering evaluation module.

- Run the GUI Composer MSP430i20xx sigma-delta ADC demo or download the Energy Measurement Design Center and Technology Guide.

- Read the application report, “Answers to Common Sigma-Delta ADC Questions on MSP MCUs”.

- Find more housekeeping functions in the technical article, “Integrating multiple functions within a housekeeping MSP430 microcontroller".