SSZT045 january 2023 DP83826E

Imagine a robot arm bending and turning, each of its axes equipped with beautifully precise motor drives, sensors and perhaps machine vision – a symphony of movement. But if the conductor wasn’t there to tell each part of the system how and when to perform its role, that robot arm could devolve into a cacophony of clashing and grinding metal.

In previous editions of our real-time control series, we’ve talked about the instruments of real-time control (RTC): sensing, actuation and processing. The last piece needed to pull it all together is the conductor: real-time communications. In this article, I will use Industry 4.0 as the basis for the discussion because it is predicated on real-time communication and control.

What’s Driving the Push toward Big Data in Automation

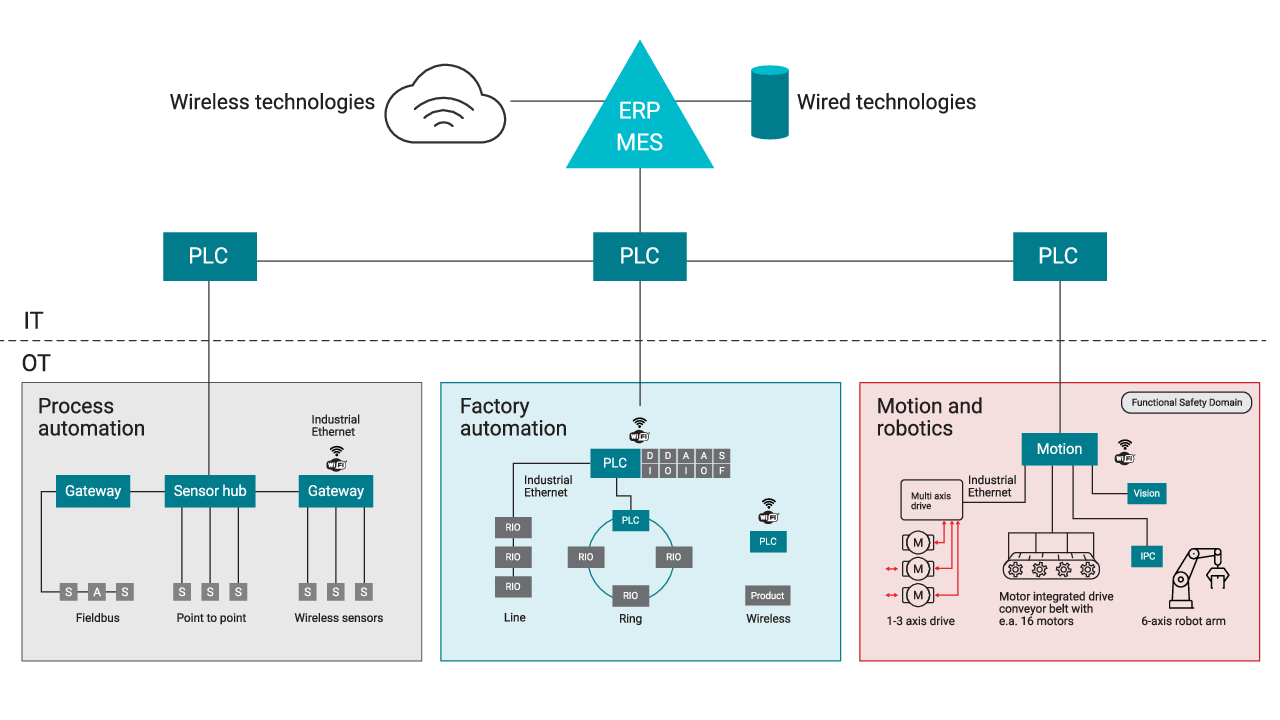

Figure 1 Communications in Industrial Automation Today

Figure 1 Communications in Industrial Automation TodayIndustrial communications implementations are starting to change. Single-pair Ethernet (SPE) can maintain existing two-wire system architectures while also supporting the faster speeds and benefits of industrial Ethernet. Advanced in situ diagnostics support both distributed and centralized monitoring and actions. And of course, SPE is able to reuse the existing two-wire infrastructure established by multiple existing fieldbuses, simplifying and minimizing the cost of convergence-driven upgrades.

Enter Ethernet

Let’s talk about timing characteristics and how they apply to Ethernet physical layers (PHYs).

The Importance of Timing Characteristics

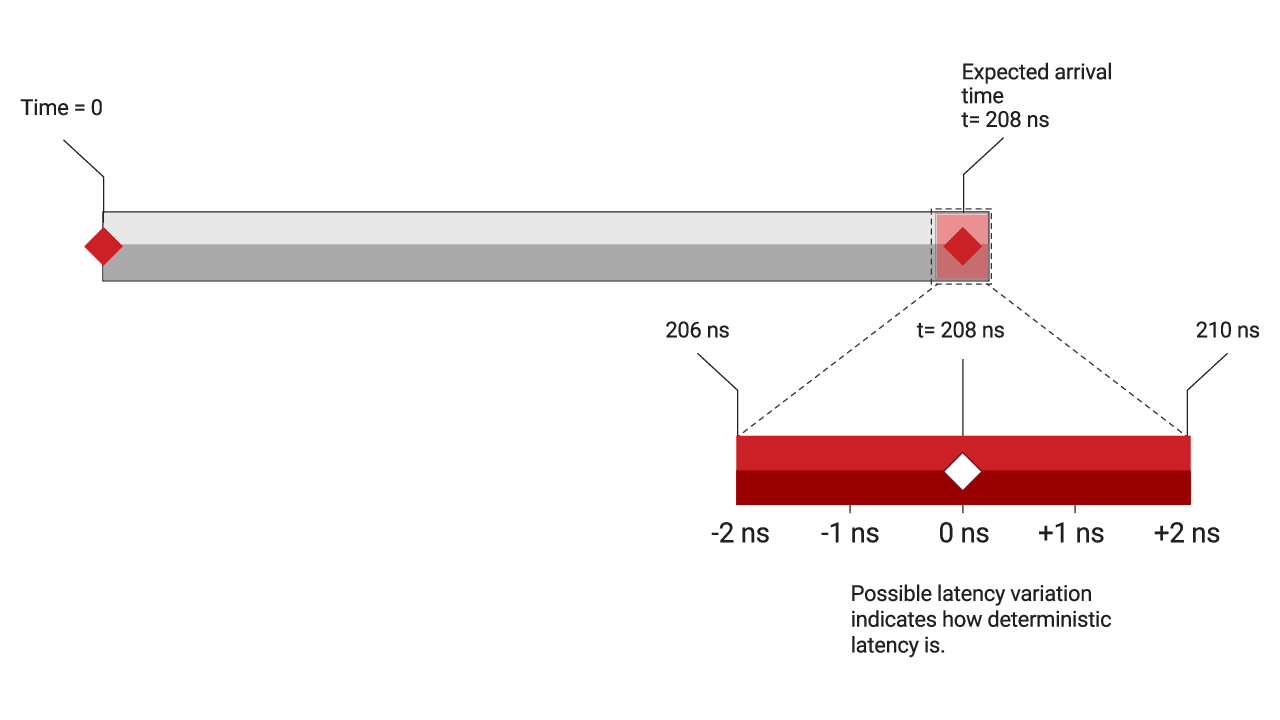

- Latency. In this context, think of latency like propagation delay: It is the length of time from when data enters a system, subsystem or subsystem component until it leaves. For example, TI’s DP83826E 10-/100-Mbps Ethernet PHY has a round-trip latency of 208 ns. Lower latency can provide faster cycle times, or enable more nodes on a bus.

- Determinism. It doesn’t matter how low the latency is if the arrival time varies widely each time data passes through the system. Determinism refers to this variation in arrival time. Very low jitter in determinism is good

determinism. Low determinism means that you’ll need to build less headroom into the system to accommodate changing latencies. Figure 2 illustrates the latency (208 ns) and determinism (2 ns) of the DP83826E. Real-time Ethernet protocols

such as EtherCAT can take advantage of low and deterministic latency in Ethernet PHYs.

Figure 2 Latency and Its Determinism

Figure 2 Latency and Its Determinism - Synchronization. Tying the timing of an entire system or several entire systems together has benefits as well. Different subsystems may need to “know” exactly when another subsystem performs an operation, both to maximize efficiency and throughput and to operate safely. Industrial Ethernet protocols all support some kind of synchronization. Time-Sensitive Networking (TSN) is one example of time synchronization that can be used in RTC systems. Institute of Electrical and Electronic Engineers (IEEE) 1588v2 – or Precision Time Protocol (PTP) – helps multiple devices remain synchronized with each other. IEEE 802.1as, also known as generalized PTP (gPTP), provides further synchronization for time-sensitive applications like RTC.

Conclusion

Additional Resources

- Learn more about TI’s SPE PHYs.

- Watch the video, “IEPE Vibration Monitoring Front End and High-Speed Data Capturing with Edge-AI Processing.”

- Read the application note, “The Importance of Single Twisted-Pair Ethernet (SPE) for Robotics System Designs.”